Powerware 9315 User Manual

Page 52

A---8

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

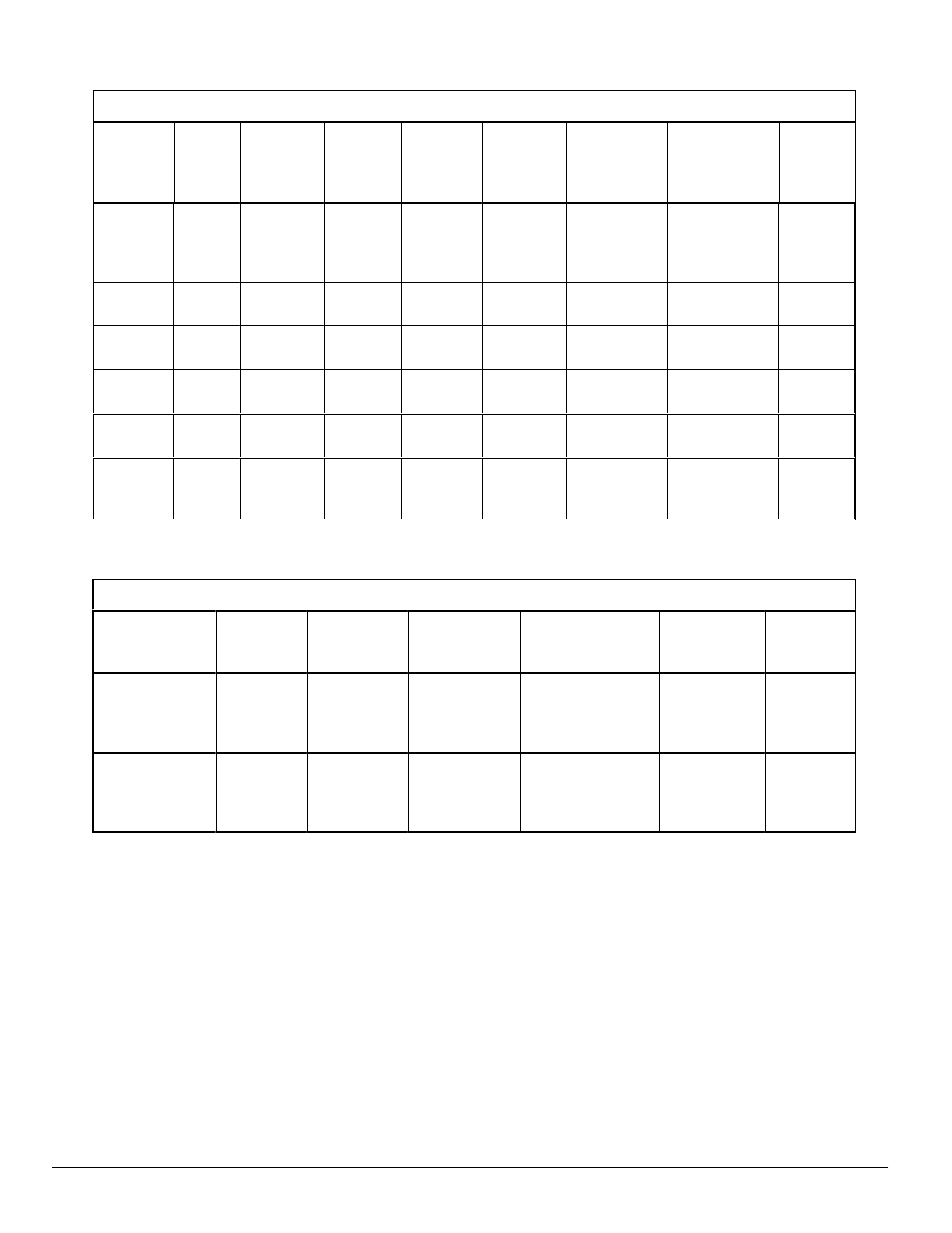

Table A--3. Tie Cabinet Power Inputs and Termination Requirements (cont.)

Internal

Hex Size

(In.)

Tightening

Torque

(lb-in)

Size of

Pressure

Termination

(CU wire)

Function

Terminal

Point in

Tie

Cabinet

Breakers

MOB 1

and 2

(Amps)

Minimum

Conductor

Size

UPS

Output

NP

Voltage

UPS

Model

300

600

(2) 4/0

AWG

400

E9, E10,

E11

Phase A,

B, C

(2) #2/0-400

kcmil or

(1) #6-600

kcmil

#2-600 kcmil,

(375)

#8-#3, (275)

3/8

400

480

(3) 300

kcmil

800

E9, E10,

E11

Phase A,

B, C

(3) #3/0-500

kcmil

#3/0-500 kcmil

(375)

3/8

500

480

(3) 300

kcmil

800

E9, E10,

E11

Phase A,

B, C

(3) #3/0-500

kcmil

#3/0-500 kcmil

(375)

3/8

All

Models

—

—

—

E12

Neutral

(12) #6--350

kcmil

(275)

3/8

All

Models

—

1/0 AWG

—

Ground

Ground

(2) #6--350

kcmil

(275)

3/8

All

Models

(Optional)

—

(2) 1/0

AWG

—

Isolated

Ground

(Optional)

Isolated

Ground

(10) #14--1/0

AWG

(275)

Slotted

Table A--4. Power Output Termination Requirements

UPS Model

Minimum

Conductor

Size

Terminal

Point in Tie

Cabinet

Function

Size of Pressure

Termination

(CU wire)

Tightening

Torque (lb-in)

10%

Internal

Hex Size

(In.)

40 through 300,

except Model

225 at 208 volt

output

Same as

input

E16, E17,

E18

Phase A, B, C (2) #6--350 kcmil

(275)

3/8

Model 225 at

208 volt output

and Models 400

and 500

Same as

input

E16, E17,

E18

Phase A, B, C (4) #6--350 kcmil

(275)

3/8

Notes for Tables A---2, A---3, and A---4:

1.

Refer to national and local electrical codes for acceptable external wiring practices.

2.

Material and labor for external wiring requirements are to be provided by

designated personnel.

3.

Power wiring size recommendation is copper wire rated at 75_C for Powerware

9315 models 40 through 300 and 90_C the Powerware 9315 400 and 500. If the

wire is run in ambient temperature higher than 30_C, larger size and/or higher

temperature wire is necessary.

4.

The output for the UPS is a separately derived source. Output neutral is bonded to

equipment ground through the main bonding jumper. Refer to NEC Article 250 and

local codes for proper grounding practices.