Control wiring interconnect details – Powerware 9315 User Manual

Page 29

23

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

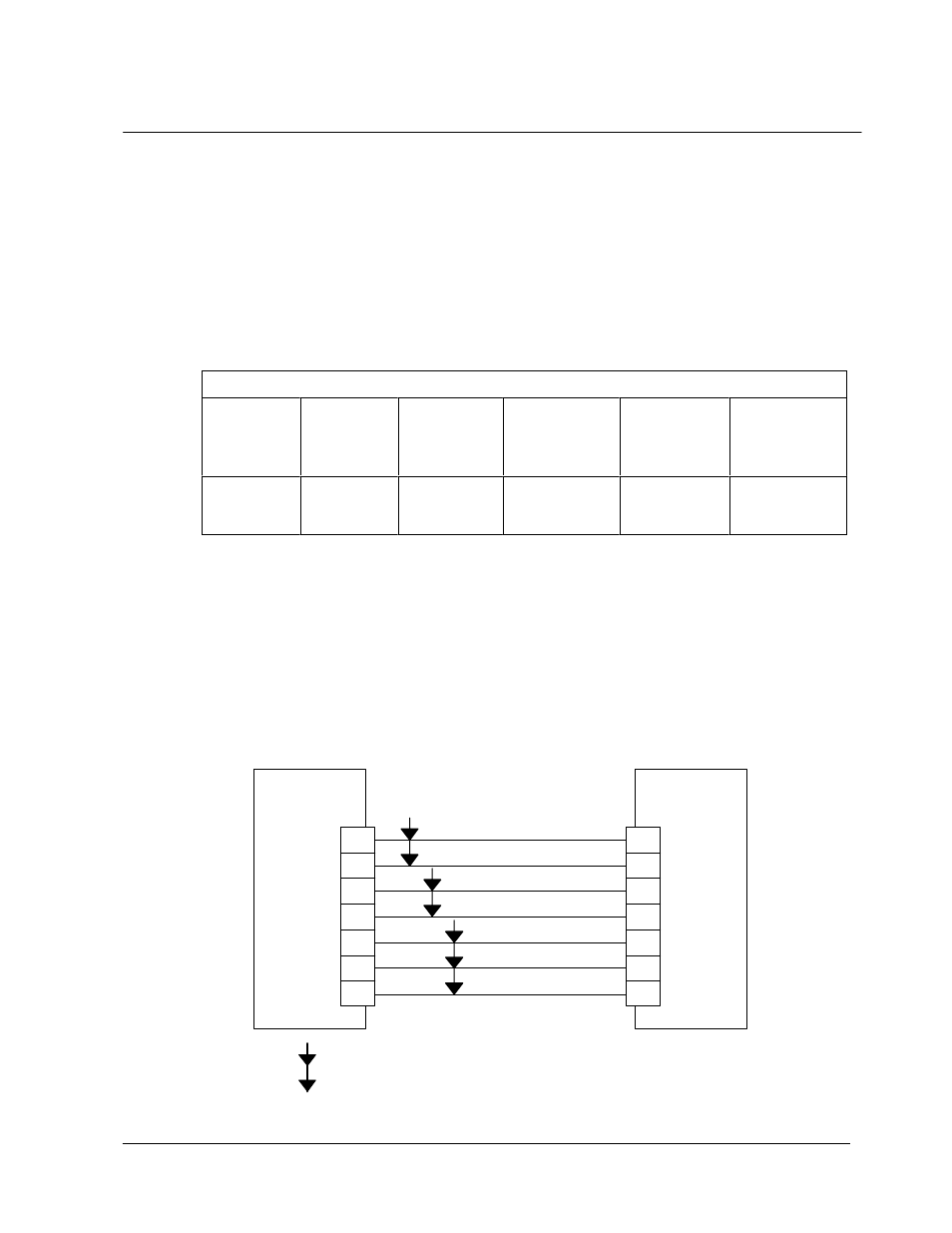

Control Wiring Interconnect Details

Each UPS module requires control signal wiring from the module to the parallel

cabinet. The purpose of signaling is to facilitate the closing of the module output

breakers and coordinate transfers to and from bypass. Once this system has been

properly placed into operation, it will operate as a parallel redundant system even if

the control wiring becomes disabled through shorts or opens. Figure 9 shows the

grouping for twisting requirements. Refer to Table A in this chapter for control

wiring recommendations and termination capability.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

Table A. Control Wiring Requirements and Termination Requirements

Connection

Points in

Parallel

Cabinet

Size of

Pressure

Termination

(lb--in)

Maximum

Voltage and

Current

Connection

Points in UPS

Size of

Pressure

Termination

(lb--in)

Recommended

Wiring Size

TB1--1

through

TB1--7

#18--#8,

(55)

24V, 0.25A

TB3--1 through

TB3--7

#22--#12,

(5--7)

#18--#12

Notes for Table A:

1.

Install the control wiring in separate conduit from the power wiring. Only

copper wire or tinned copper wire should be used.

2.

Control wiring is NEC class 2 (IEC 950 SELV).

3.

Class 1 methods are recommended for control wiring.

4.

Control wiring should be twisted pairs and twisted triple as shown in Figure 9.

Indicates grouping for twisting requirements.

1

2

3

4

5

6

7

1

2

3

4

5

6

7

UPS

Module 1

(or 2)

Parallel

Cabinet

MOB#1

(#2)

TB3

TB1

Figure 9. Grouping for Twisting Requirements