Powerware 9315 User Manual

Page 49

A---5

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

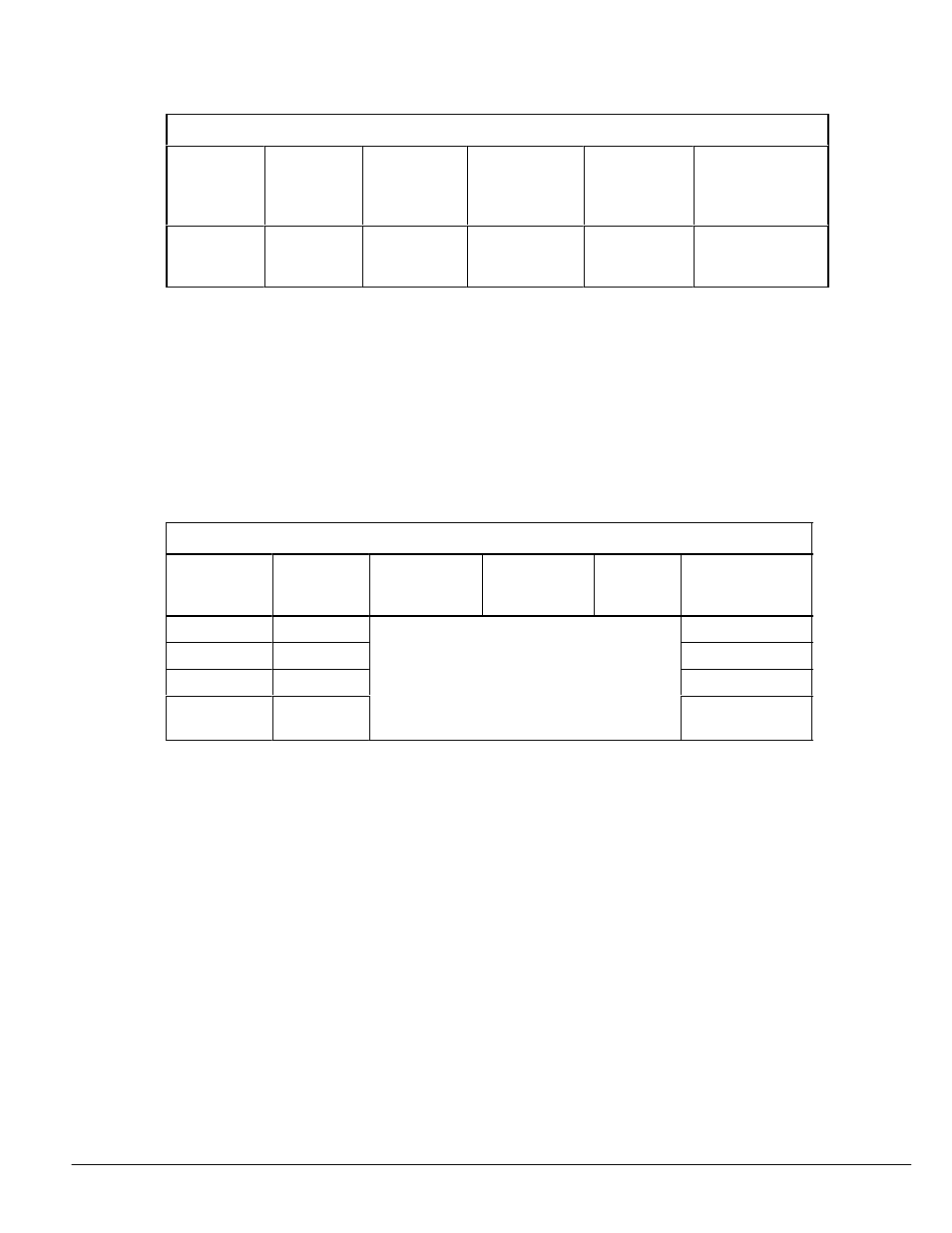

Table A--1. Control Wiring Requirements and Termination Requirements

Connection

Points in Tie

Cabinet

Size of

Pressure

Termination

(lb-in)

Maximum

Voltage and

Current

Connection

Points in UPS

Size of

Pressure

Termination

(lb-in)

Recommended

Wiring Size

TB1--1

through

TB1--7

#18--#8,

(55)

24V, 0.25A

TB3--1 through

TB3--7

#22--#12,

(5--7)

#18--#12

Notes for Table A---1:

1.

Install the control wiring in separate conduit from the power wiring. Only copper

wire or tinned copper wire should be used.

2.

Control wiring is NEC class 2 (IEC 950 SELV).

3.

Class 1 methods are recommended for control wiring.

4.

Control wiring should be twisted pairs and twisted triple as shown in Figure 9.

Table A--2. UPS Power Cable Terminations and Connection Points

Connection

Point in UPS

Function

Size of

Pressure

Termination

Tightening

Torque

N--M (lb--in)

Int Hex

Size (In.)

Connection Point

in Tie Cabinet

E9

Phase A

E9

E10

Phase B

Refer to the applicable Powerware 9315

E10

E11

Phase C

Refer to the applicable Powerware 9315

UPS installation manual for this information

E11

E12

Neutral/

Gnd

UPS installation manual for this information

E12