Troubleshooting – Lochinvar Power-fin 1701 User Manual

Page 40

3

Troubleshooting

40

Service Manual

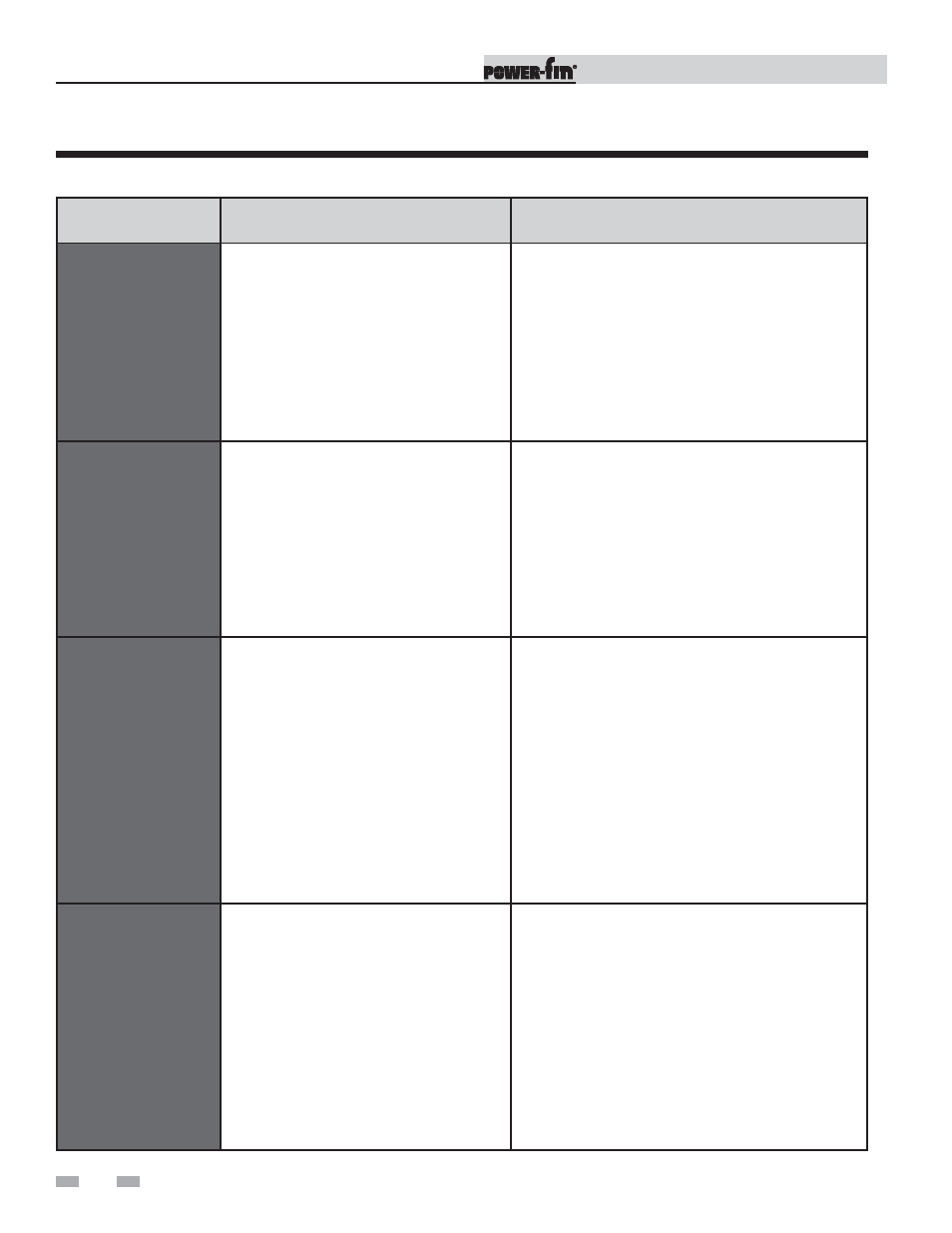

FAULT

DESCRIPTION

CORRECTIVE ACTION

APS Open

(Lockout will reset

automatically after 5

minutes or may be reset

immediately once

condition has been

corrected. Press the

RESET button on the

SMART SYSTEM display

to reset.)

The air pressure switch did not make within

1 minute after the combustion air blower has

been energized.

• Check air filter. Clean or replace as necessary.

• Vent/air intake lengths exceed the maximum allowed

lengths.

• Check for blockage or obstruction in vent/air inlet pipe

or at terminations.

• Verify combustion air blower is operating. Replace if

necessary.

APS Closed

(Lockout will reset

automatically after 5

minutes or may be reset

immediately once

condition has been

corrected. Press the

RESET button on the

SMART SYSTEM display

to reset.)

The SMART SYSTEM control sensed that

the air pressure switch was closed before the

combustion air blower was energized.

• Check for jumper on air pressure switch.

• Check for an unusually high negative draft in the vent

stack.

Wrong ID Plug

Control module ID plug does not match

parameter L5.

• Verify that ID plug is connected properly to connector

X5 on the control module.

• Verify that the wiring in the ID plug is not cut or

damaged and that the wiring connectors are seated

properly in the plug.

• Verify that the number on the ID plug matches the

number in parameter L5. If not, replace the control

module.

• When replacing control modules, verify that the

number in parameter L5 matches the number on the

ID plug. If so, press the ENTER button on the SMART

SYSTEM display. If not, replace the control module.

Temp O/Shoot

(Lockout will reset

automatically after 5

minutes or may be reset

immediately once

condition has been

corrected. Press the

RESET button on the

SMART SYSTEM display

to reset.)

The stack temperature has exceeded the set

parameters for the boiler/water heater.

• Inspect the heat exchanger. Reference page 30 of

this manual for the procedure on how to clean the flue

side of the heat exchanger.

• Inspect the flue sensor and associated wiring.

Measure the resistance of the flue sensor and

compare to Table 3C on page 33 of this manual.

Replace the sensor if necessary.

• Verify that the vent/air intake pipes are properly

installed and that there are no obstructions.

• Replace the main control board.

Table 3F (continued from previous page) Troubleshooting Chart - Fault Messages Displayed on Operator Interface