Gas connections – Lochinvar ARMOR 151 User Manual

Page 47

Installation & Operation Manual

47

7

Gas connections

(continued)

Gas pressure

The gas pressure must remain between 4 inches w.c. (natural),

8 inches w.c. (LP) minimum and 14 inches w.c. (natural and

LP) maximum during stand-by (static) mode and while in

operating (dynamic) mode. If an in-line regulator is used, it

must be a minimum of 10 feet from the Armor water heater. It

is very important that the gas line is properly purged by the gas

supplier or utility company. Failure to properly purge the lines

or improper line sizing, will result in ignition failure.

The problem is especially noticeable in NEW LP installations

and also in empty tank situations. This can also occur when

a utility company shuts off service to an area to provide

maintenance to their lines.

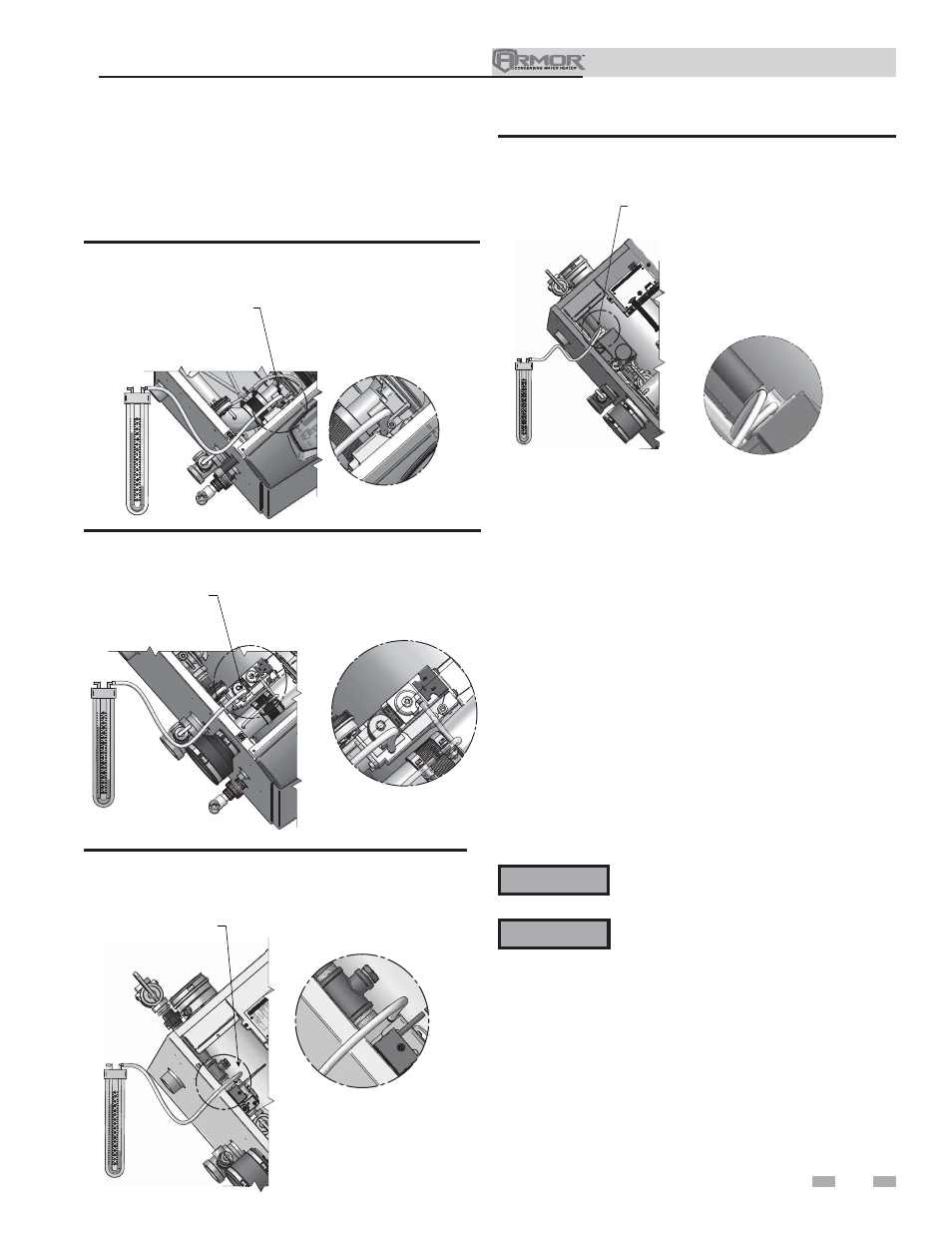

DETAIL

LOOSEN THE SET SCREW ONE (1) FULL TURN AND

PLACE THE MANOMETER TUBING OVER THE

PRESSURE TAP

Figure 7-6 Inlet Gas Supply Check - Models 151 - 286

DETAIL

LOOSEN THE SET SCREW ONE (1) FULL TURN AND

PLACE THE MANOMETER TUBING OVER THE

PRESSURE TAP

Figure 7-7 Inlet Gas Supply Check - Model 400

DETAIL

LOOSEN THE SET SCREW ONE (1) FULL TURN AND

PLACE THE MANOMETER TUBING OVER THE

PRESSURE TAP

Figure 7-8 Inlet Gas Supply Check - Model 501

DO NOT adjust or attempt to measure

gas valve outlet pressure. The gas valve is

factory-set for the correct outlet pressure.

This setting is suitable for natural gas and

propane, requiring no field adjustment.

Attempting to alter or measure the gas valve

outlet pressure could result in damage to

the valve, causing potential severe personal

injury, death, or substantial property

damage.

Failure to follow all precautions could result

in fire, explosion, or death!

ƽ WARNING

ƽ WARNING

Gas valve replacement

The gas valve MUST NOT be replaced with a conventional gas

valve under any circumstances. As an additional safety feature,

this gas valve has a flanged connection to the venturi and blower.

17. Check burner performance by cycling the system while

you observe burner response. The burner should ignite

promptly. Flame pattern should be stable. Turn system

off and allow burner to cool, then cycle burner again to

ensure proper ignition and flame characteristics.

DETAIL

REMOVE THE 1/8” (3 MM) PIPE PLUG ON

THE INLET FLANGE TO THE VALVE AND

INSTALL A SUITABLE 1/8” (3 MM) FITTING

(FIELD SUPPLIED) FOR THE MANOMETER

TUBING.

Figure 7-9 Inlet Gas Supply Check - Models 601 - 801