General, Venting – Lochinvar ARMOR 151 User Manual

Page 19

Installation & Operation Manual

3

General

venting

(continued)

6. Priming

and

Cementing:

a. Handle fittings and pipes carefully to prevent

contamination

of

surfaces.

b. Apply a liberal even coat of primer to the fitting

socket.

c. Apply a liberal even coat of primer to the pipe end to

approximately 1/2" beyond the socket depth.

d. Apply a second primer coat to the fitting socket.

e. While primer is still wet, apply an even coat of

approved cement to the pipe equal to the depth of

the

fitting

socket.

f. While primer is still wet, apply an even coat of

approved cement to the fitting socket.

g. Apply a second coat of cement to the pipe.

h. While the cement is still wet, insert the pipe into the

fitting, if possible twist the pipe a 1/4 turn as you insert

it.

NOTE: If voids are present, sufficient cement was

not applied and joint could be defective.

i. Wipe excess cement from the joint removing ring or

beads as it will needlessly soften the pipe.

Table 3A Vent Pipe, and Fittings

PVC/CPVC Air intake/vent connections

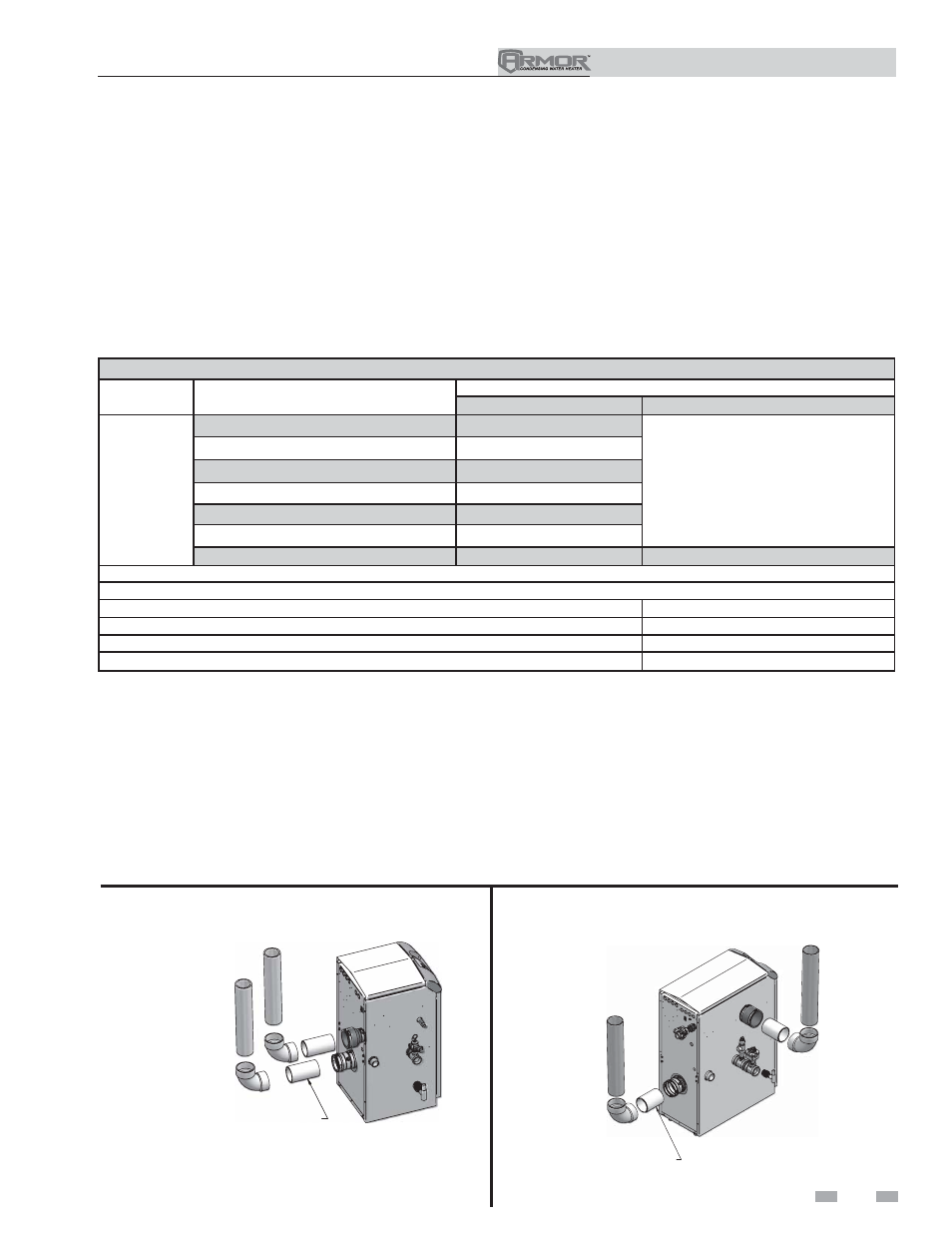

1. Combustion Air Intake Connector (FIG.’s 3-9 thru 3-11) - Used to provide combustion air directly to the unit from

outdoors. A fitting is provided on the unit for final connection. Combustion air piping must be supported per guidelines

listed in the National Mechanical Code, Section 305, Table 305.4 or as local codes dictate.

2. Vent Connector (FIG.’s 3-9 thru 3-11) - Used to provide a passageway for conveying combustion gases to the outside. A

transition fitting is provided on the unit for final connection. Vent piping must be supported per the National Building Code,

Section 305, Table 305.4 or as local codes dictate.

3” CPVC PIPE SUPPLIED WITH

WATER HEATER MUST BE USED

FOR VENT CONNECTION

NOTE:

CPVC VENT PIPE AND VENT FITTINGS MUST BE USED

IN CLOSET AND ALCOVE INSTALLATIONS.

VENT

AIR

Figure 3-9 Near Water Heater PVC/CPVC Venting

Models 151 - 200

4" CPVC PIPE SUPPLIED WITH

WATER HEATER MUST BE USED FOR

VENT CONNECTION

NOTE: CPVC VENT PIPE AND VENT FITTINGS MUST BE USED

IN CLOSET AND ALCOVE INSTALLATIONS.

VENT

AIR

19

*Use of FasNSeal Flex smooth inner wall vent is to be used in vertical or near vertical sections only, taking precaution to ensure

no sagging occurs of the vent system. Connect to the FasNSeal rigid vent using specially designed adapters and sealing method,

see manufacturer’s instructions.

Figure 3-10 Near Water Heater PVC/CPVC Venting

Models 286 - 601

All vent pipe materials and fittings must comply with the following:

Item

Material

Standards for installation in:

United States

Canada

Vent pipe and

fittings

PVC Plastic Pipe, Schedules 40, 80, & 120

ANSI/ASTM D1785

CPVC and PVC venting must be ULC-S636

Certified. IPEX is an approved manufacturer

in Canada supplying vent material listed to

ULC-S636.

PVC Plastic Pipe Fittings, Schedule 40

ANSI/ASTM D2466

PVC Plastic Pipe Fittings, Schedule 80

ANSI/ASTM D2467

PVC - DWV Pipe and Fittings

ANSI/ASTM D2665

CPVC Plastic Pipe, Schedule 40 & 80

ANSI/ASTM F441

CPVC Plastic Pipe Fittings, Schedule 80

ANSI/ASTM F439

AL29-4C

UL1738

ULC-S636

NOTICE: DO NOT USE CELLULAR (FOAM) CORE PIPE

Approved Stainless Steel Vent Manufacturers

Make

Model

ProTech Systems (Simpson Dura-Vent Co.)

FasNSeal Vent / FasNSeal Flex* Vent

Z-Flex (Nova Flex Group)

Z-Vent

Heat Fab (Selkirk Corporation)

Saf-T Vent