System piping – Lochinvar ARMOR 151 User Manual

Page 37

Installation & Operation Manual

6

System piping

System water piping methods

Observe a minimum of 1 inch clearance around all un-insulated

hot water pipes when openings around the pipes are not

protected by non-combustible materials.

General piping information

Basic steps are listed below along with illustrations on the

following pages (FIG.’s 6-4 thru 6-8), which will guide you

through the installation of the Armor water heater.

1. Connect the cold water supply to the inlet side of the water

heater.

2. Connect the hot water supply to the outlet side of the water

heater.

3. Install a backflow preventer on the cold feed make-up water

line.

4. Install the factory supplied pump as shown in FIG.’s 6-4

thru 6-8.

5. Install an expansion tank on the system supply. Consult the

tank manufacturer’s instruction for specific information

relating to tank installation. Size the expansion tank for the

required system volume and capacity.

6. Install a drain valve at the lowest point of the system.

7. This appliance is supplied with a relief valve sized in

accordance with ASME Boiler and Pressure Vessel Code,

Section IV (“Heating Boilers”). Pipe the discharge of the

safety relief valve to a suitable drain to prevent injury in

the event of pressure relief. Pipe the discharge to a drain.

Provide piping that is the same size as the safety relief valve

outlet. Never block the outlet of the safety relief valve.

See the *piping illustrations included in this section, FIG.’s 6-4

thru 6-8 for suggested guidelines in piping the Armor water

heater.

*Please note that these illustrations are meant

to show system piping concept only, the

installer is responsible for all equipment and

detailing required by local codes.

NOTICE

MODEL

PADDLE SIZE

SENSITIVITY SCREW

ADJUSTMENT

Note: Paddles are included with the flow switch.

151

#1

9 turns

200

#1

6 turns

286

#3

8¾ turns

400

#1

8 turns

501

#1

7½ turns

601

#1

7 turns

701

#1

6½ turns

801

#1

5½ turns

RELIEF VALVE

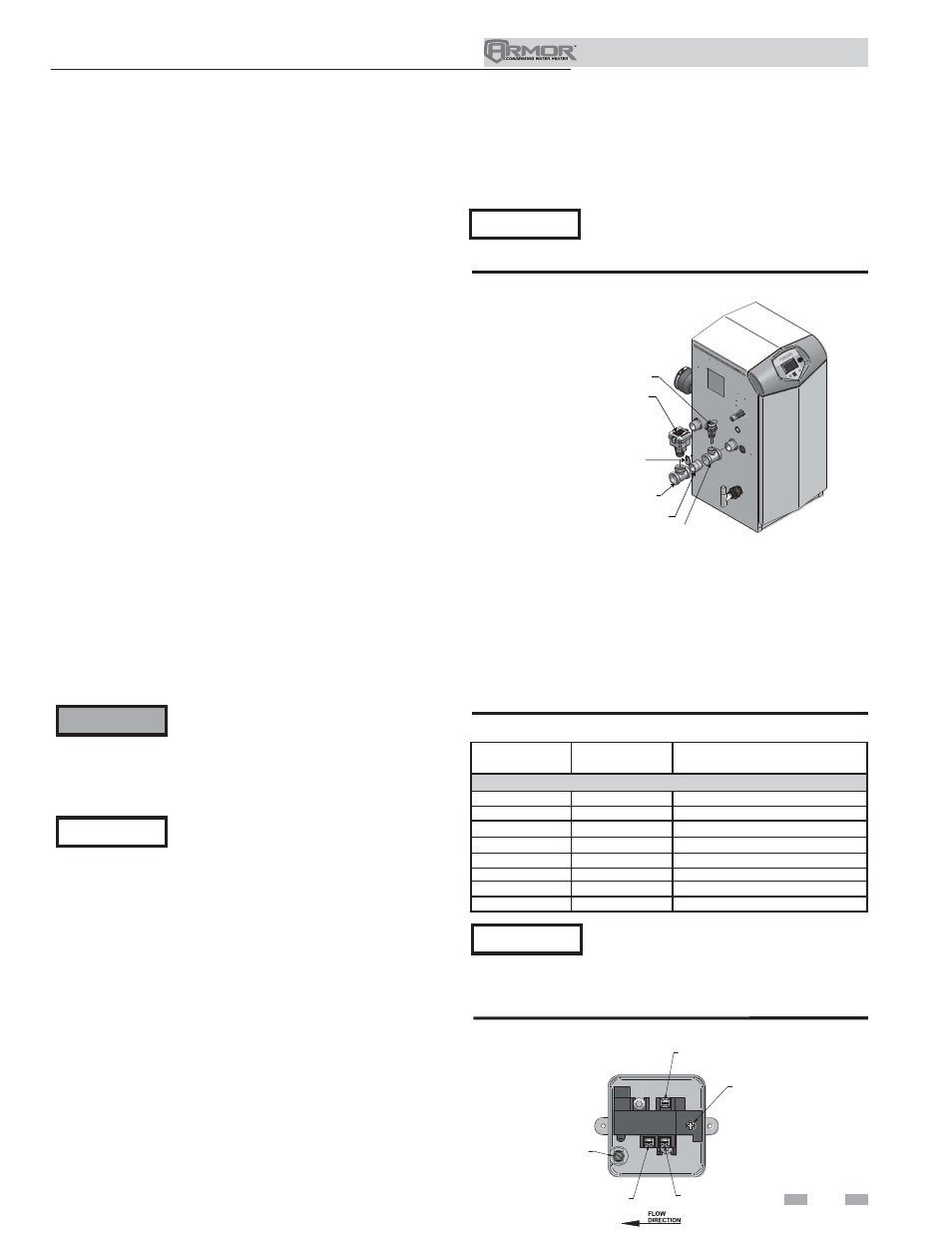

FLOW SWITCH

PADDLE

TEE WITH 1” FITTING ON TOP

CLOSE NIPPLE

TEE WITH 3/4” FITTING ON TOP

For Example: If using a 1 1/4 inch pipe size (Models

AWN151 - AWN200) select paddle #1.

6. Install the assembled flow switch into the 1 inch fitting of

the tee installed in Step 4 (see FIG. 6-1).

Flow switch adjustment

Refer to Table 6A for the proper setting of the sensitivity screw.

For reference, the position of the screw prior to setting should be

turned clockwise with a Phillips driver until it stops (FIG. 6-2).

Proceed to turn the screw counterclockwise the amount of turns

listed in Table 6A based on the model.

Consult the manufacturer’s instructions for wiring the flow

switch to your system.

NOTICE

Be sure to install flow switch so that the arrow

on the flow switch is pointing in the direction

of the flow (see FIG. 6-2).

Table 6A Paddle Size / Sensitivity Screw Adjustment

Figure 6-1 Flow Switch and Relief Valve Installation

NORMALLY

OPEN

SENSITIVITY

ADJUSTMENT

NORMALLY

CLOSED

COMMON

GROUND

NOTICE

Turn the sensitivity screw clockwise to increase

the flow rate required to activate the switch.

Turn the sensitivity screw counterclockwise to

decrease the flow rate required to activate the

switch.

Flow switch and relief valve installation

Basic steps are listed below to guide you through the installation

of the flow switch and relief valve provided with the unit.

1. Install the tee with the 3/4 inch fitting positioned vertically

and on the top as shown in FIG. 6-1.

2. Install the relief valve into the 3/4 inch fitting of the tee

installed in Step 1 (FIG. 6-1).

3. Install the close nipple on the downstream side of the

temperature and pressure relief valve tee (FIG. 6-1).

4. Install the tee with the 1 inch fitting positioned vertically

and on the top (FIG. 6-1).

5. Attach the paddle to the flow switch per the manufacturer’s

instructions. Reference Table 6A to select the correct

paddle for the pipe size used (consult the manufacturer’s

instructions for a detailed explanation).

ƽ WARNING

The relief valve, tee and other necessary

fittings are shipped in the install kit with the

water heater and are to be field installed.

Figure 6-2 Flow Switch Adjustment

37