Hydronic piping, Installation & operation manual – Lochinvar KBII-I-O REV C 81 - 286 User Manual

Page 45

45

Installation & Operation Manual

6

Hydronic piping

(continued)

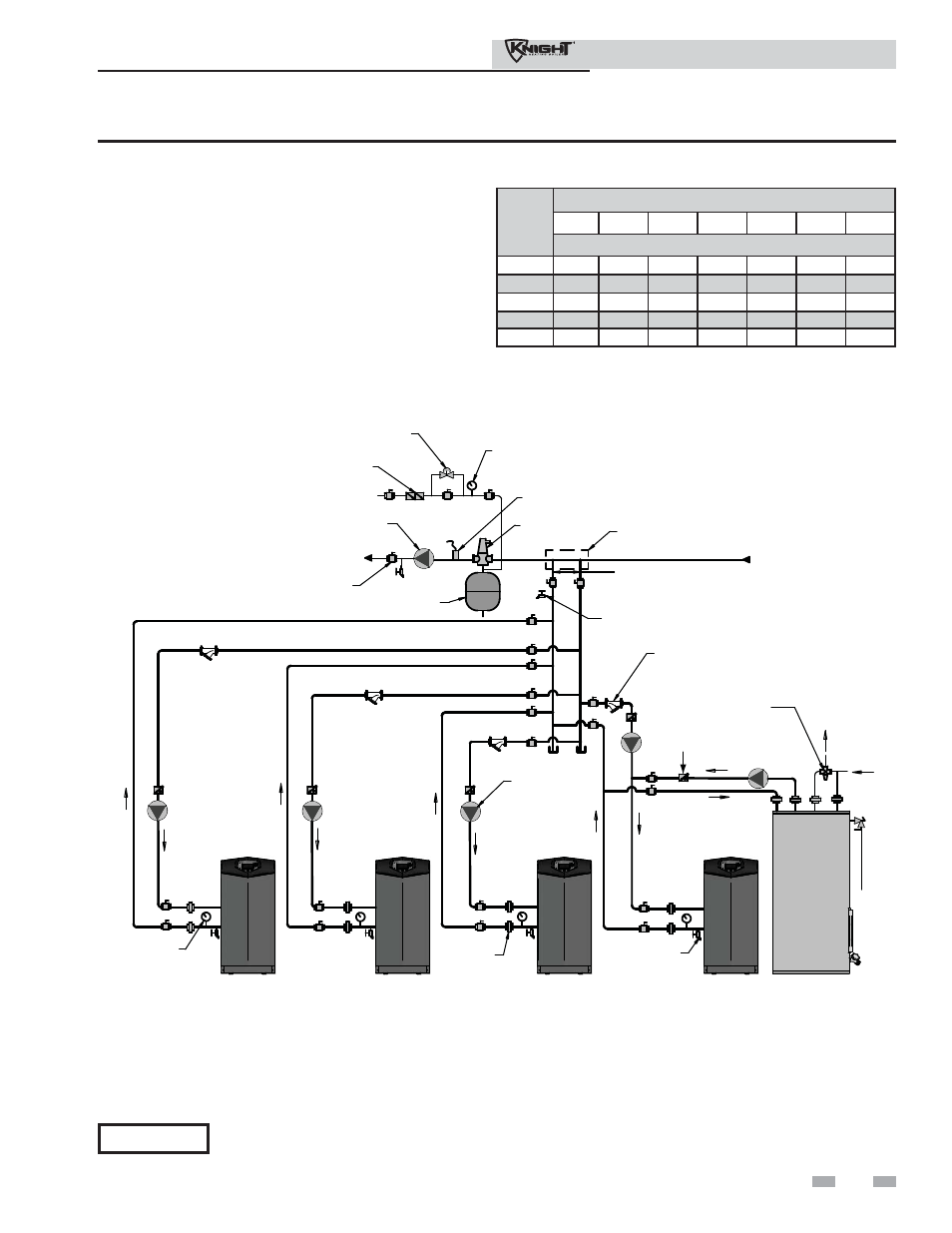

BOILER 1

(LEADER)

INDIRECT

DHW TANK

DOMESTIC

HOT WATER

CIRCULATOR

BACKFLOW

PREVENTER

PRESSURE

REDUCING VALVE

PRESSURE

GAUGE

ANTI-SCALD

MIXING VALVE

COLD WATER

IN

TEMPERATURE /

PRESSURE

GAUGE

AIR SEPARATOR

EXPANSION

TANK

BALL VALVE

(TYPICAL)

UNION

(TYPICAL)

DRAIN POINT

(TYPICAL)

MAKE UP WATER

FROM

SYSTEM

TO

SYSTEM

BOILER 2

(MEMBER 1)

BOILER

CIRCULATOR

BOILER 3

(MEMBER 2)

BOILER 4

(MEMBER 3)

SYSTEM SUPPLY

SENSOR

DRAIN

SYSTEM

CIRCULATOR

NOT TO EXCEED 4 PIPE DIA OR MAX. OF 12" APART

Y-STRAINER

(RECOMMENDED)

(TYPICAL)

MAY SUBSTITUTE LOW LOSS HEADER

HOT

WATER

OUT

FLOW CHECK

VALVE

Figure 6-10 Multiple Boilers - Non-Zoned Primary/Secondary Piping

Model

Number of Units

2

3

4

5

6

7

8

Required Pipe Sizes

81

1-1/4" 1-1/2"

2"

2"

2-1/2" 2-1/2" 2-1/2"

106

1-1/2"

2"

2"

2-1/2" 2-1/2" 2-1/2"

3"

151

2"

2"

2-1/2" 2-1/2"

3"

3"

3-1/2"

211

2"

2-1/2"

3"

3"

3-1/2"

4"

4"

286

2-1/2" 2-1/2"

3"

3-1/2" 3-1/2"

4"

5"

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

NOTICE