Hydronic piping, Minimum temperature rise – Lochinvar KBII-I-O REV C 81 - 286 User Manual

Page 38

Installation & Operation Manual

38

It is required that near boiler piping

systems utilize the Primary/Secondary

configuration shown in FIG. 6-10 only.

The use of other near boiler piping

configurations could result in improper

building and system flow rates leading

to inadvertent boiler high limit

shutdowns and poor system

performance.

NOTICE

Pump sizing and flow requirements are

based on 20 feet of piping, 4 - 90°

elbows, and 2 - fully ported ball valves.

NOTICE

6

Hydronic piping

Variable speed pump option

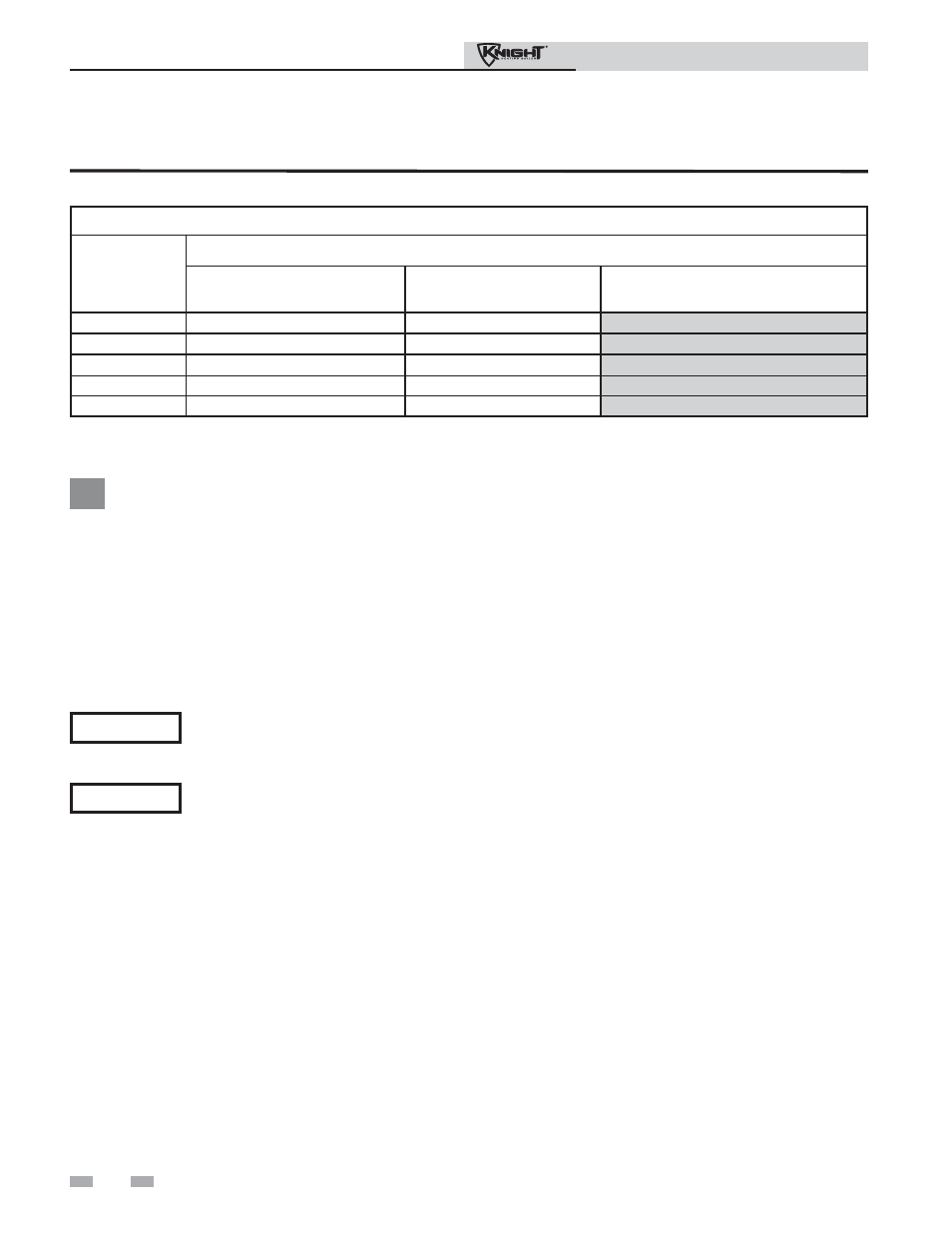

Table 6B Recommended Variable Speed Pumps

*The minimum temperature rise is derived from the chart in FIG. 6-3 with the firing rate and pump speed at 100% as shown in

the table above.

The shaded regions of pump coverage are only available for applications with 230V (60 Hz) supply voltage, all others are

to be 115V. (A field supplied relay is required to connect the 230V pump listed in the shaded area in Table 6B to the boiler

high voltage terminal strip.)

Variable speed pump setup

Before operation, ensure the following:

- Pump is set for an input signal of 0 - 10Vdc by the dip switches on the pump control

- Pump is set for external signal control (if applicable)

- Pump is set for linear output (if applicable)

- If pump does not come equipped with a 0 - 10 Vdc input option, an optional module

will be required from the vendor

Minimum Temperature Rise*

Model

Pump

Grundfos

UP26-96 FC/VS

TACO

0013 IFC VS

Wilo

Stratos 1.25 3 x 30

81

20.3

20.3

21.7

106

22.3

21.0

21.5

151

21.2

19.8

19.1

211

26.8

25.1

23.6

286

26.7

24.3

21.9