Troubleshooting, Gas valve adjustment procedure – Lochinvar Sync Condensing Boiler 1.3 User Manual

Page 55

55

3

Troubleshooting

(continued)

Gas valve adjustment procedure

If adjustment of the gas valve is deemed necessary, use the

following procedures: (Note: The procedures below are

model specific.)

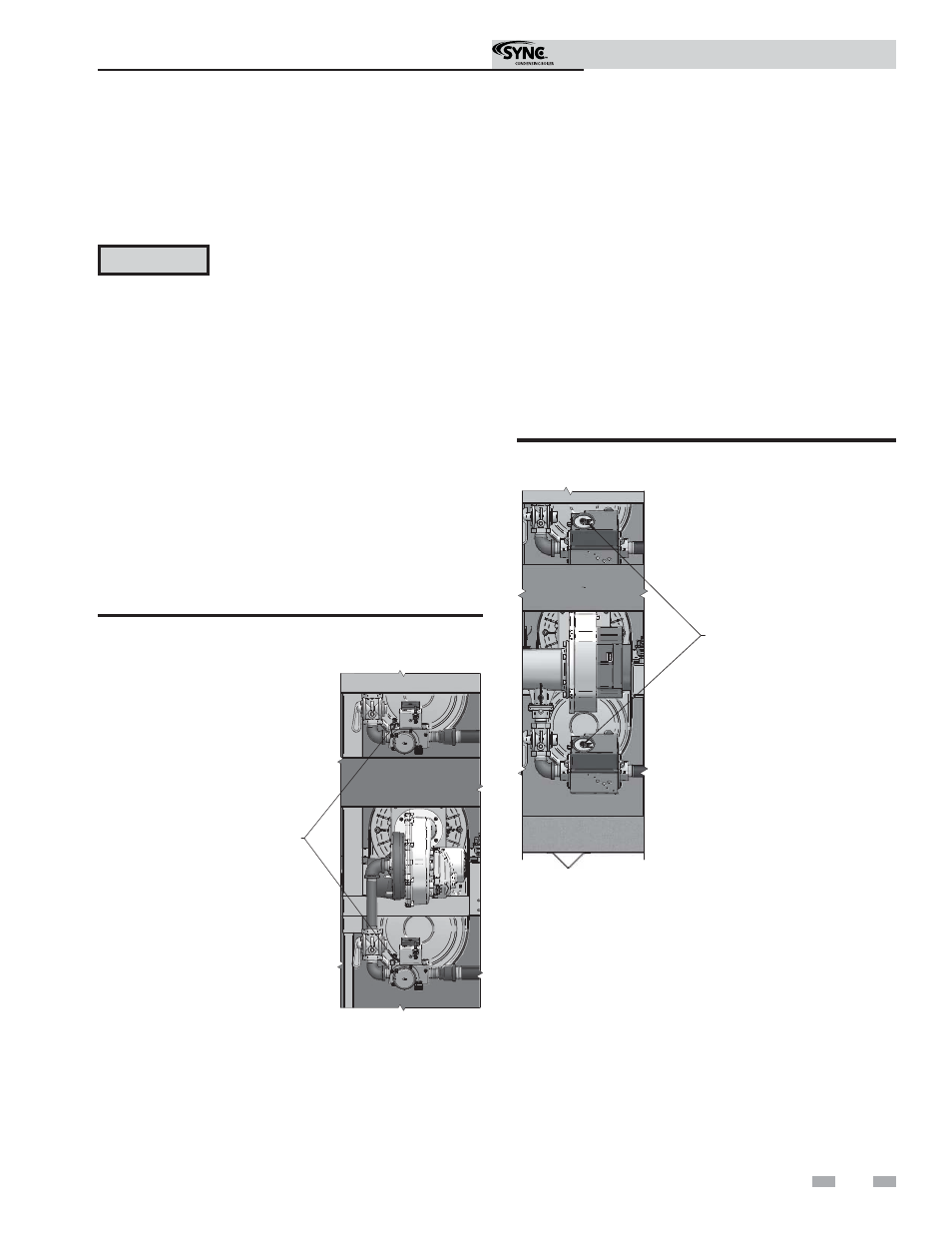

THROTTLE ADJUSTMENT SCREW

Figure 3-2 Gas Valve Adjustment: Model 1.0

Model 1.0

Locate the throttle adjustment screw on top of the gas valve,

see FIG. 3-2. Using a screwdriver, turn the screw a 1/4 turn

counterclockwise to increase CO

2

levels or a 1/4 turn

clockwise to decrease CO

2

levels. After one adjustment on

the valve, follow the Combustion Analysis Procedure on

page 54 of this manual to measure the combustion.

If combustion is still not within the specified range,

repeat the procedure. This procedure SHOULD NOT

be performed more than four (4) times. If after four (4)

adjustments and the combustion is still not within the

specified range, revisit the possible causes in Table 3G on

page 54 or replace the gas valve.

CAUTION

Under normal operating conditions this

valve should not need adjusting.

Models 1.3 - 1.5

Locate the throttle adjustment screw on top of the gas valve,

see FIG. 3-3. Using an Allen wrench, turn the screw a 1/4

turn counterclockwise to increase CO

2

levels or a 1/4 turn

clockwise to decrease CO

2

levels. After one adjustment on

the valve, follow the Combustion Analysis Procedure on page

54 of this manual to measure the combustion.

If combustion is still not within the specified range, repeat

the procedure. This procedure SHOULD NOT be performed

more than four (4) times. If after four (4) adjustments and

the combustion is still not within the specified range, revisit

the possible causes in Table 3G on page 54 or replace the gas

valve.

THROTTLE ADJUSTMENT

SCREW (REMOVE BLUE COVER)

Figure 3-3 Gas Valve Adjustment: Models 1.3 - 1.5

Service Manual