Troubleshooting – Lochinvar Sync Condensing Boiler 1.3 User Manual

Page 46

3

Troubleshooting

46

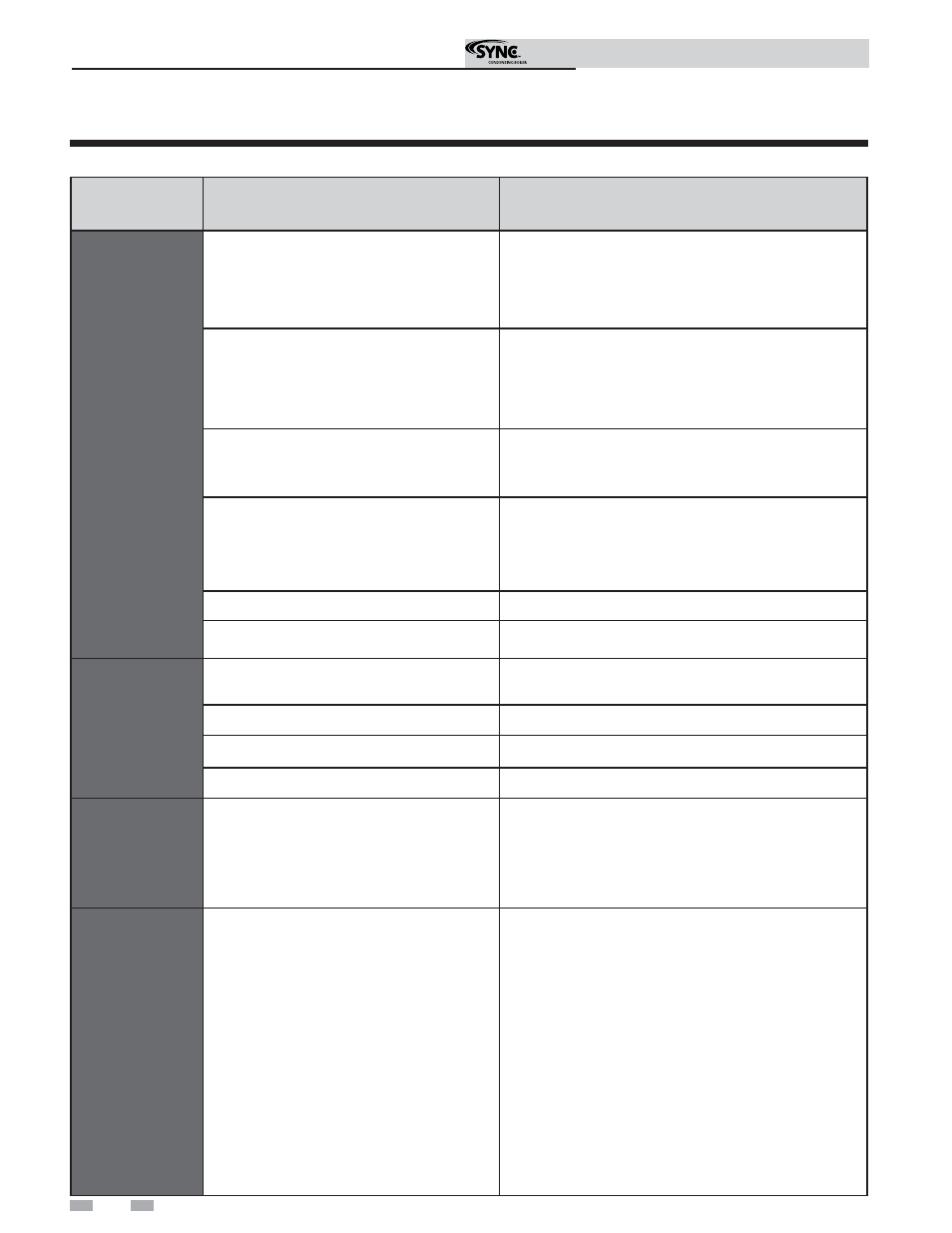

Table 3E Troubleshooting Chart - Noisy System

FAULT

CAUSE

CORRECTIVE ACTION

Noisy

Operation

- Supply gas problem. Natural gas pressures

should be between 4 inches w.c. (1.0 kPa)

and 14 inches w.c. (3.5 kPa). LP gas

pressures should be between 8 inches w.c.

(2.0 kPa) and 14 inches w.c. (3.2 kPa).

• Refer to Section 6 - Gas Connections of the SYNC

Installation and Operation Manual for detailed

information concerning the gas supply.

- Gas/air mixture problem.

• Refer to the Gas Valve Adjustment Procedure on

page 55 of this manual for the proper gas valve setting.

Verify that the vent/air intake lengths do not exceed the

maximum listed in the General Venting section of the

SYNC Installation and Operation Manual.

- Dirty/damaged burner.

• Refer to page 39 in this manual for the burner removal

and inspection procedure. Clean or replace the burner

as

necessary.

- Low water flow through the heat exchanger.

•

Refer to Section 6 - Hydronic Piping of the

SYNC Installation and Operation Manual for

minimum flow rates. Verify that the boiler is piped in a

primary/secondary fashion and that the boiler and

system pump are running on a call for heat.

- Air in the piping system.

• Properly purge all air from the piping system.

- Low system water pressure.

•

Verify system pressure is a minimum of 12 psi

(82.7

kPa).

No Pump

Operation -

Boiler Pump

System Pump

or

HW Pump

- Blown fuse.

• Replace fuse F5 on the control board, see page 43 of

this

manual.

- Faulty pump.

• Replace pump.

- Internal fault on control board.

• Replace main control board.

- Faulty pump relay.

• Replace relay.

Relief Valve

Opening

-

System pressure exceeds relief valve

setting.

•

Lower the system pressure below the 50 psi

(344.7 kPa) rating of the supplied relief valve or replace

the standard relief valve with a higher rated valve up to

the maximum pressure of the heat exchanger.

• Improperly sized expansion tank.

Gas Pressure

Switch

(will require a

manual reset once

the condition has

been corrected.

Press the RESET

button on the

display to reset.)

Either the manual reset low gas pressure

switch or the manual reset high gas pressure

switch tripped.

• Reset the pressure switches.

• Measure the supply gas pressure to determine cause

of failure. Natural gas pressures should be between

4 - 14 inches w.c. (1.0 - 3.5 kPa) and LP gas

pressures should be between 8 - 14 inches w.c.

(2.0 - 3.2 kPa).

• Refer to Section 6 - Gas Connections of the SYNC

Installation and Operation Manual for detailed

information concerning the gas supply.

• Correct the supply gas pressure if necessary.

• Check for a loose or misplaced jumper if pressure

switches are not installed.

Service Manual