Troubleshooting, Before troubleshooting, Check the following – Lochinvar Sync Condensing Boiler 1.3 User Manual

Page 43: Check control module fuses

3

Troubleshooting

(continued)

Label all wires prior to disconnection

when servicing controls. Wiring errors can

cause improper and dangerous operation.

Always disconnect power to the boiler

before servicing. Failure to comply could

result in severe personal injury, death, or

substantial property damage.

Never jumper (bypass) any device except

for momentary testing as outlined in the

Troubleshooting chart. Severe personal

injury, death, or substantial property

damage can result.

Before troubleshooting:

1. Have the following items:

a.

Voltmeter that can check 120 VAC, 24 VAC, and

12

VDC.

b. Continuity

checker.

c. Contact

thermometer.

2. Check for 120 VAC (minimum 102 VAC to maximum

132 VAC) to boiler.

3. Make sure thermostat is calling for heat and contacts

(including appropriate zone controls) are closed. Check

for 24 VAC between thermostat wire nuts and ground.

4. Make sure all external limit controls are installed and

operating.

Check the following:

1. Wire connectors to control module are securely plugged

in at the control module and originating control.

2. Gas

pressures:

• Maximum: 14 inches w.c. (3.5 kPa) natural,

14 inches w.c. (3.2 kPa) LP with no flow (lockup)

or with boiler on

• Minimum: 4 inches (5 inches on 1.0 models only) w.c.

(1.0 kPa) natural, 8 inches w.c. (2.0 kPa) LP with gas

flowing (verify during boiler startup)

Check control module fuses

ALWAYS check control module fuses

before replacing control module or any

major components (blower, etc.). If one

of these fuses is blown, it can prevent the

control module or other components from

operating.

1. Turn OFF the power to the boiler at the external line

switch.

2. Remove the front access cover.

3. Remove the two (2) screws securing the control panel to

the unit to gain access to the control module.

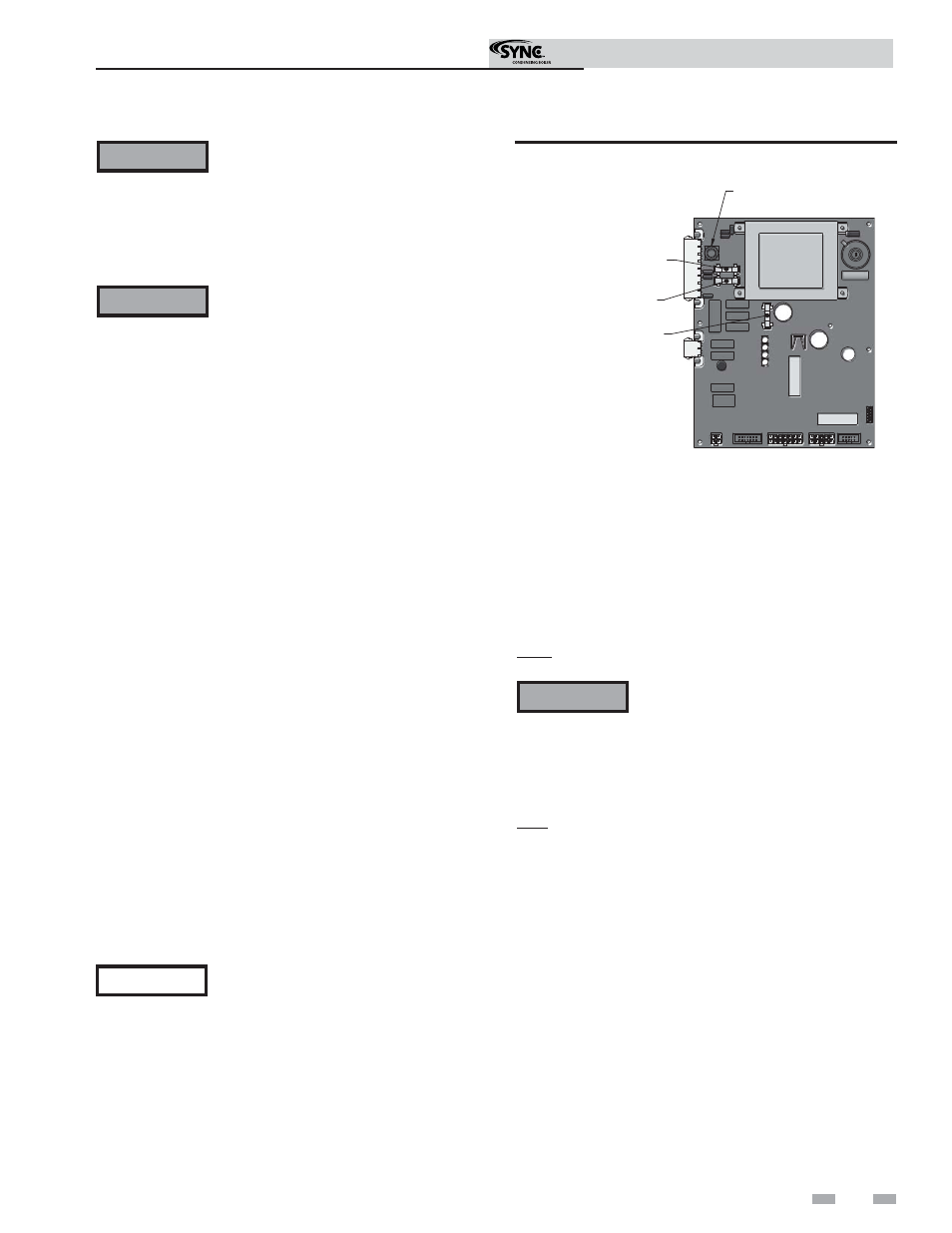

F4 - 3.15 AMP FUSE

BLOWER

F3 - 1.25 AMP FUSE

MAIN BOARD

F5 - 5 AMP FUSE

PUMPS

F2 - 3.15 AMP FUSE

24V SUPPLY

Figure 3-1 Control Module Fuses

6. The boiler is shipped with six (6) spare fuses in a plastic

bag located under the low water cutoff on the control

module.

7. If necessary, replace open fuse (F3 is 1.25 amps, F2 and F4

are 3.15 amps, and F5 is 5 amps).

Note: Fuses F2 - F5 are all slow blow fuses.

Do not jumper fuse or replace with any

fuse except as specified. Failure to comply

could result in severe personal injury,

death, or substantial property damage.

8. Re-install the control module cover using the nuts

removed in Step 4.

Note: If the spark wire was unplugged, reattach it to the

control.

9. Re-install the control panel using the two (2) screws

removed in Step 3. Re-install the front access cover after

fuse inspection.

10. Restore power to the boiler at the external line switch

and verify boiler operation (Section 9 - Start-up in the

SYNC Boiler Installation and Operation Manual) after

completing boiler service.

ƽ WARNING

ƽ WARNING

NOTICE

ƽ WARNING

Service Manual

43

4. Remove the two (2) nuts on the control module cover.

5. Inspect fuses F2, F3, F4, and F5, see FIG 3-1.