Maintenance, Test low water flow conditions, Notice – Lochinvar Sync Condensing Boiler 1.3 User Manual

Page 41: Test procedure, Service manual

41

2

Maintenance

Test low water flow conditions

NOTICE

This test is to be carried out once the

SYNC boiler is completely piped in

with adequate gas and water flow.

Once the test is completed, ensure

that the isolation valve is opened up to

allow full water flow.

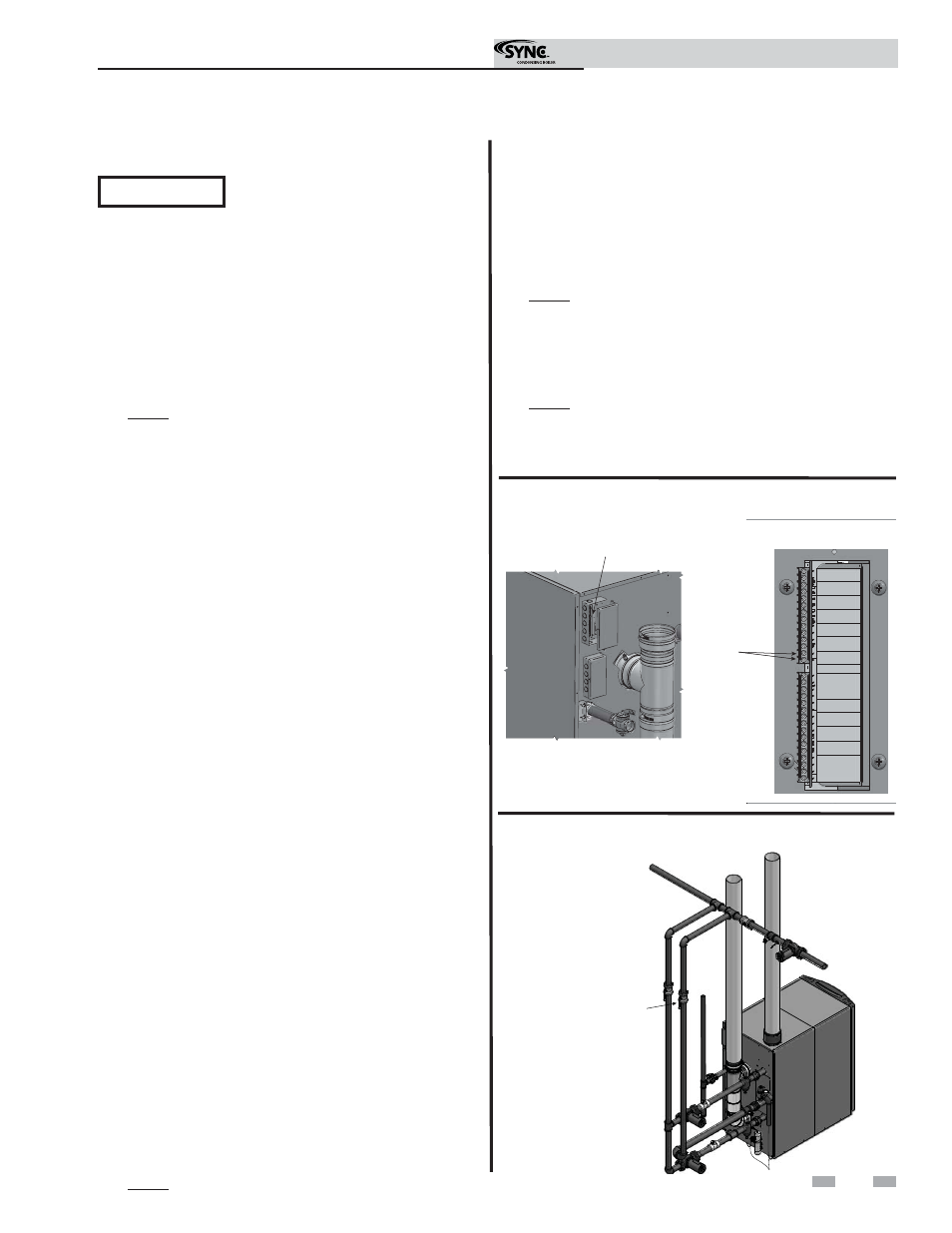

Figure 2-4 Adjust outlet isolation valve

Test procedure

1. Set the SYNC to operate with the demand configuration

parameter set to 1 (Cascade Set Point Thermostat-

Based).

NOTE: This can be accomplished by selecting the

demand configuration parameter in the Service/Setup

Menu. See Section 1 of this manual for complete details

of the SmartTouch controls.

2. Set the system setpoint to the max user setpoint. Max

user setpoint will allow the boiler to operate without

reaching this setpoint. The boiler will require a load

large enough to dissipate a large portion of the heat it is

generating.

3. Simulate a call for heat by placing a jumper wire across

the enable contacts on the low voltage terminal strip

located at the rear of the unit (FIG. 2-3).

4. Allow the unit to progress through its normal diagnostics

and pre-purge programming.

5. Allow the unit to fire and operate until the temperatures

stabilize. This occurs when the inlet and outlet

temperatures are rising together and the Delta T (

ࣼ T)

is maintained.

6. When the unit stabilizes, begin to slowly shut off the

isolation valve on the outlet piping of the boiler (see

FIG. 2-4). This will begin to restrict the flow and

simulate a low flow condition.

7. While slowly shutting off the isolation valve, refer to

the Burner Screen to watch the behavior of the boiler.

On this screen, you will witness each individual control

module modulating its’ respective burner’s firing rate

while reacting to the rising

ࣼ T.

8. When the

ࣼ T reaches 50˚F for an individual heat

exchanger, the control for the heat exchanger will

attempt to modulate the firing rate down to protect it

from low flow conditions.

9. When the

ࣼ T reaches 60˚F for an individual heat

exchanger, the control module for the heat exchanger

will turn off the respective burner.

NOTE: The Temperature Menu will show the inlet and

outlet temperatures for each individual heat exchanger.

ADJUST OUTLET

ISOLATION VALVE

ONLY

10. Restrict the isolation valve until both control modules have

shut down. If both control modules have been shut down,

the test was successful.

11. Disconnect the jumper wire from the low voltage terminal

strip connected in step 3.

12. If necessary, reset the demand configuration in the Service/

Setup Menu to the required operational mode.

NOTE: See Section 1 of this manual for complete details of

the SmartTouch controls.

13. Completely open the isolation valve on the outlet piping of

the boiler.

14. Resume operation.

NOTE: This lockout is a soft lockout. Once the

ࣼ T has

decreased to an acceptable level and there is a call for heat,

the unit will fire again to meet the demand.

Figure 2-3 Low voltage terminal strip & enable contacts

LOW VOLTAGE CONNECTION BOARD

1 ALARM

LBL20052 REV B

30 SHIELD GND

MOD BUS

0 - 10V INPUT

2 CONTACTS

3 RUN TIME

4 CONTACTS

5 LOUVER

6 PROVING

7 MODULE 2

8 FLOW SWITCH

9 MODULE 1

10 FLOW SWITCH

29 A

26 SENSOR

25 TANK

24 SENSOR

23 OUT DOOR

22 SENSOR

21 SYSTEM

20 (-)

19 (+)

18 SHIELD GND

17 B

16 A

15 SHIELD GND

14 W

13 R

11 TANK

12 THERMOSTAT

28 B

27 SHIELD GND

CASCADE

ENABLE

ENABLE

CONTACTS

Service Manual