Troubleshooting – Lochinvar Sync Condensing Boiler 1.3 User Manual

Page 51

3

Troubleshooting

(continued)

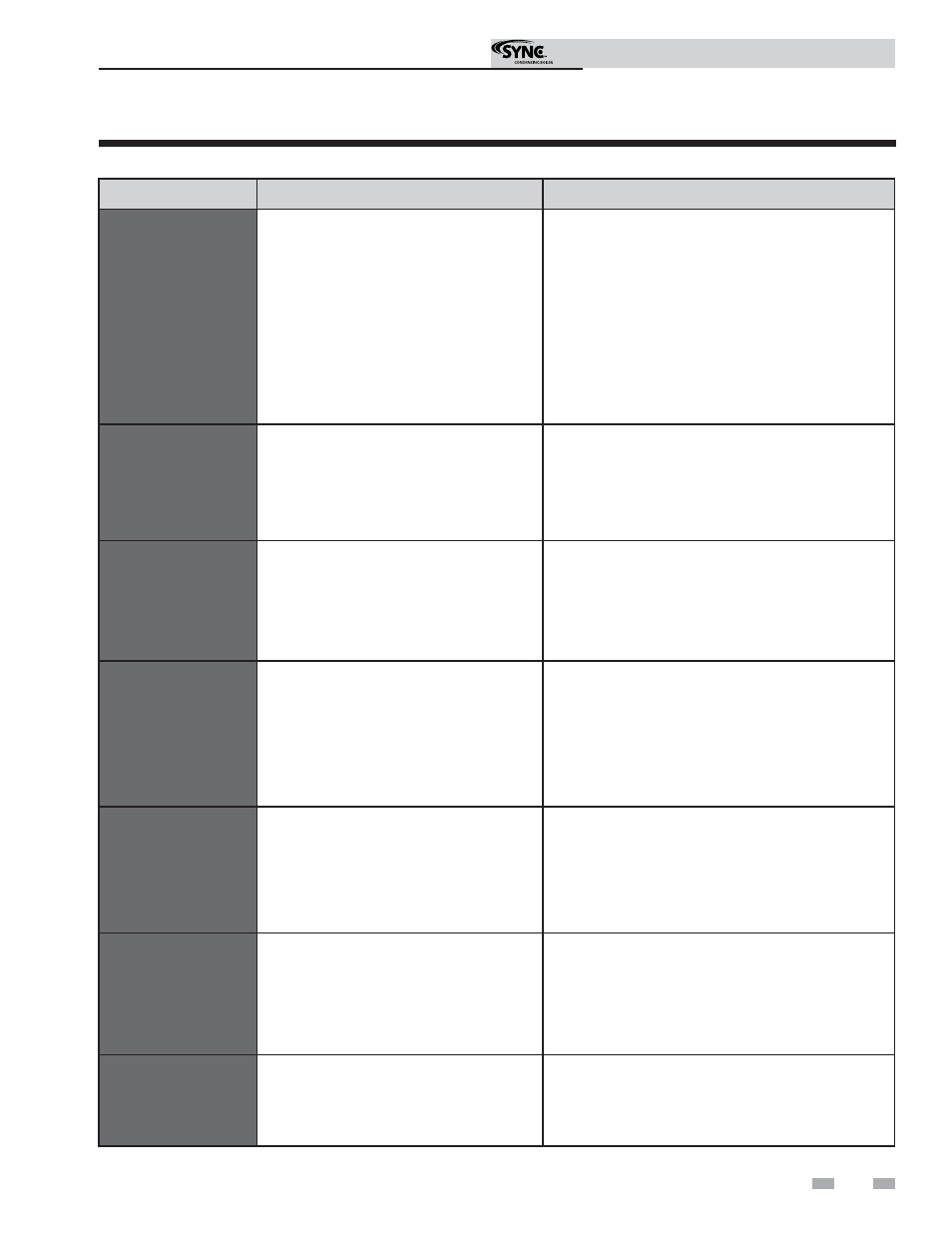

Table 3F (continued from previous page) Troubleshooting Chart - Fault Messages Displayed on Boiler Interface

FAULT

DESCRIPTION

CORRECTIVE ACTION

Blower RPM’s

Too High

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

display to reset.)

The actual fan rpm is 30% higher than what

is being called for.

• Vent/air intake lengths exceed the maximum allowed

lengths. Refer to Section 2 - General Venting of the

SYNC Installation and Operation Manual for

proper

lengths.

• Check for obstruction or blockage in the vent/air

intake pipes or at terminations.

• Check the wiring connections at the fan and at the

main control board.

• Replace the fan.

• Replace the main control board.

Sensor Open

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

display to reset.)

Either the inlet water or outlet water

temperature sensor has been disconnected.

• Check the sensors and their associated wiring.

Repair or replace the sensor or wiring if damaged.

• Measure the resistance of the sensors and compare

the resistance to the tables on page 45 of this

manual.

• Replace the sensor if necessary.

Sensor Shorted

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

display to reset.)

Either the inlet water or outlet water

temperature sensor has been shorted.

• Check the sensors and their associated wiring.

Repair or replace the sensor or wiring if damaged.

• Measure the resistance of the sensors and compare

the resistance to the tables on page 45 of this

manual.

• Replace the sensor if necessary.

Flue Sensor

Open / Removed

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

display to reset.)

The flue sensor has been disconnected or

removed from the flue.

• Check the sensor and its associated wiring. Repair

or replace the sensor or wiring if damaged.

• Measure the resistance of the sensors and compare

the resistance to the tables on page 45 of this

manual.

• Replace the sensor in flue.

• Replace the sensor if necessary.

Flue Sensor

Shorted

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

display to reset.)

The flue sensor has been shorted.

• Check the sensor and its associated wiring. Repair

or replace the sensor or wiring if damaged.

• Measure the resistance of the sensors and compare

the resistance to the tables on page 45 of this

manual.

• Replace the sensor if necessary.

Louver Proving

Switch

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

display to reset.)

An optional remote proving switch is not

making.

• Check function of remote devices.

• Check for loose or misplaced jumper if proving switch

is not installed.

Tank Open

Sensors equipped with an internal limit (such

as the Lochinvar Squire

®

Indirect Tank), the

limit has opened due to temperature (195°F)

or the sensor has become disconnected.

• Check the tank temperature.

• Repair or replace the sensor wiring if damaged.

• Replace the sensor if necessary.

Service Manual

51