Troubleshooting, Caution – Lincoln Electric POWER FEED IM892-C User Manual

Page 76

E-4

TROUBLESHOOTING

E-4

POWER FEED™ 25M

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

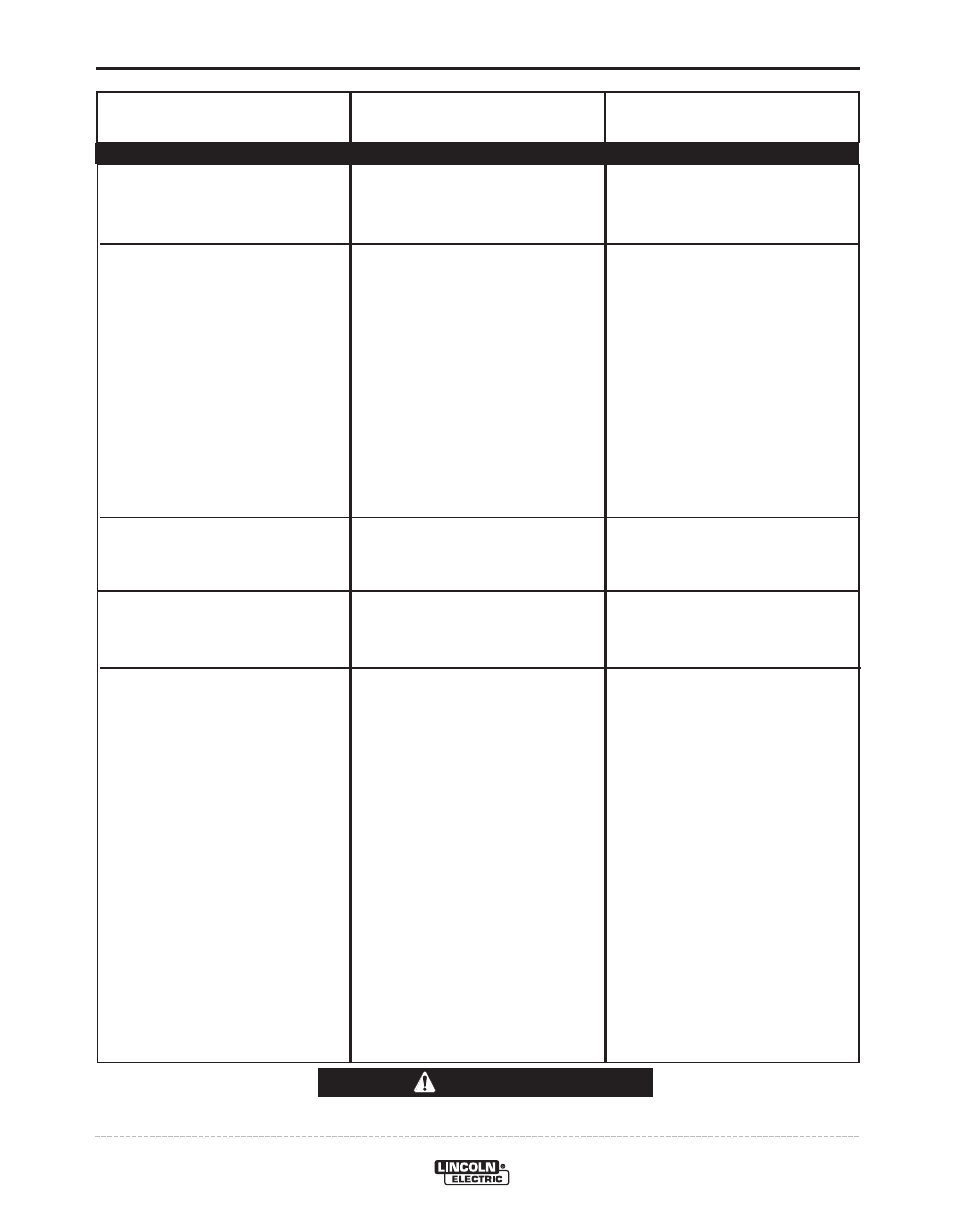

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Wire feed speed consistently oper-

ates at the wrong value.

Variable or "hunting" arc.

P o o r a r c s t a r t s w i t h s t i c k i n g o r

"blast-offs", weld porosity, narrow

and ropy looking bead.

The wire feed speed/amperage and

voltage/trim display work during pre-

set but show nothing during welding.

1. The wire feeder gear setting is not

properly set.

1. Wrong size, worn and/or melted

contact tip.

2. Worn work cable or poor work

connection.

3. Wrong polarity.

4. T h e g a s n o z z l e i s e x t e n d e d

beyond the contact tip or the wire

stickout is too long.

5. Poor gas shielding on processes

requiring gas.

1. I m p r o p e r p r o c e d u r e s o r t e c h -

niques.

1. T h e s o f t w a r e i n t h e P O W E R

FEED™ 25M must be upgraded.

1. Verify the POWER FEED™-15

software setting matches the gear

mounted. See the Instruction

Manual for setting the gear speed.

1. Replace the contact tip.

2. Verify all work and electrode con-

nections are tight and that the

c a b l e s a r e i n g o o d c o n d i t i o n .

Clean/replace as necessary.

3. Adjust polarity to the recommend-

ed procedure.

4. Adjust the gas nozzle and shorten

the stickout to 3/8 to 1/2 inches.

5. C h e c k g a s f l o w a n d m i x t u r e .

R e m o v e o r b l o c k s o u r c e s o f

drafts.

1. S e e " G a s M e t a l A r c W e l d i n g

Guide". (GS-100).

1. C o n t a c t t h e l o c a l a u t h o r i z e d

Lincoln Field Service Shop.

Output Problems