Operation, B-44 – Lincoln Electric POWER FEED IM892-C User Manual

Page 60

B-44

OPERATION

B-44

POWER FEED™ 25M

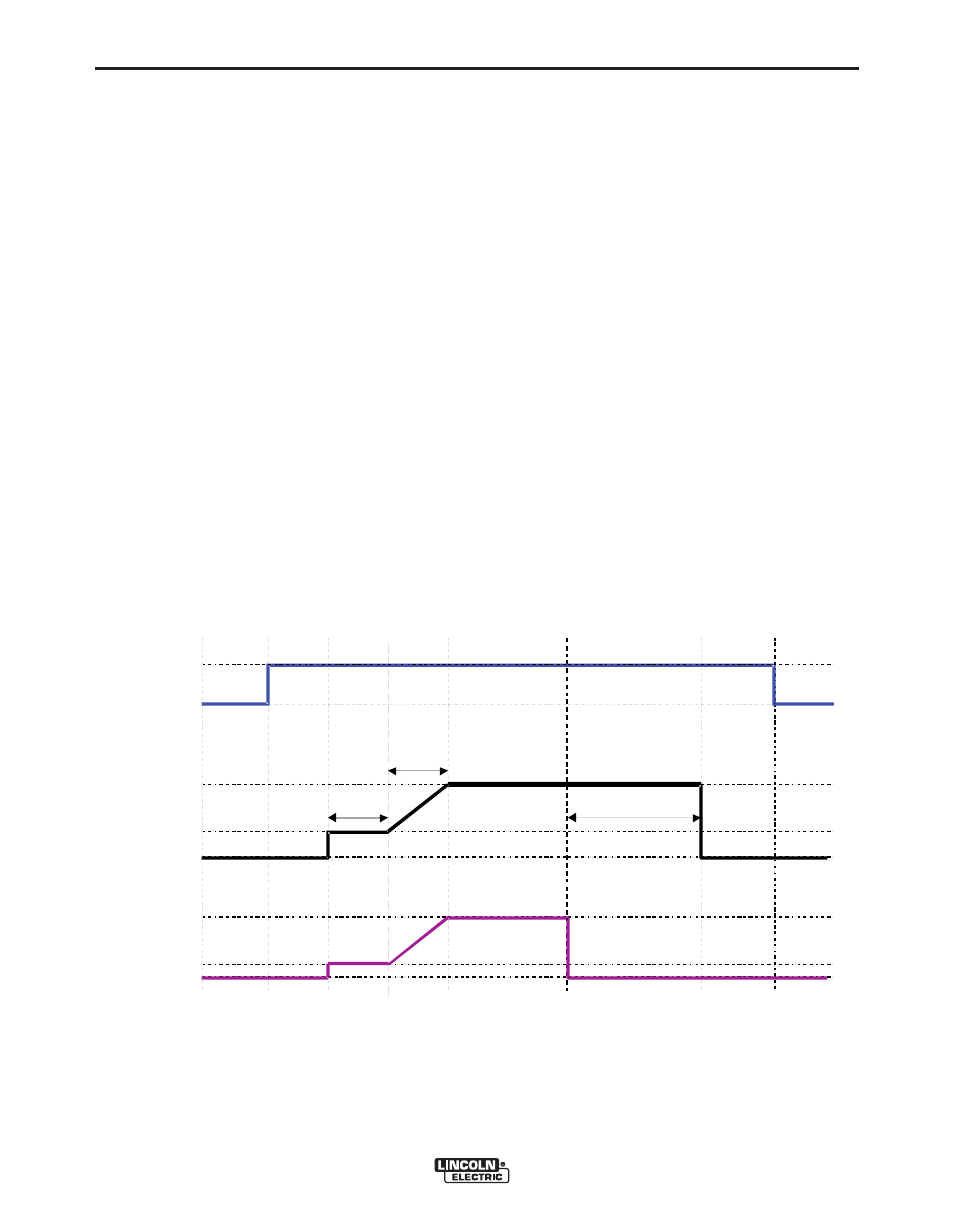

EXAMPLE 2 - 2 STEP TRIGGER: Improved Arc Start

and Arc End. Tailoring the arc start and arc end is a

common method for reducing spatter and improving

weld quality. This can be accomplished with the Start

and Burnback functions set to a desired values and

Crater set to OFF. (See Figure B.20)

For this sequence,

PREFLOW:

Shielding gas begins to flow immediately when the

gun trigger is pulled.

RUN-IN:

After preflow time expires, the power source regulates

to the start output and wire is advanced towards the

work piece at the Run-In WFS. If an arc is not estab-

lished within 1.5 seconds, the power source output

and wire feed speed skips to the weld settings.

UPSLOPE:

Once the wire touches the work and an arc is estab-

lished, both the machine output and the wire feed

speed ramp to the weld settings throughout the start

time. The time period of ramping from the start set-

tings to the weld settings is called UPSLOPE.

WELD:

After upslope, the power source output and the wire

feed speed continue at the weld settings.

BURNBACK:

As soon as the trigger is released, the wire feed

speed is turned OFF and the machine output contin-

ues for the burnback time.

POSTFLOW:

Next, the machine output is turned OFF and shielding

gas continues until the post flow timer expires.

Shielding

Gas

Idle

Preflow

Strike

Upslope

Weld

Burnback

Postflow

Idle

WFS

On

Off

Run-in

Off

Weld

Off

Weld

Ar

c

Es

ta

bl

ish

ed

Tr

ig

ge

r P

ul

le

d

Tr

ig

ge

r R

el

ea

se

d

2 Step Trigger

Start = ON

Crater = OFF

Burnback = ON

1.5 sec max.

Start

Start time

Burnback Time

Power

Source

Output

FIGURE B.20