In table f.3, Troubleshooting & repair, Input rectifier test (continued) – Lincoln Electric INVERTEC SVM129-B User Manual

Page 65

6. Replace the input rectifier when any of the

tests are NOT OK.

NOTE: When installing a new input rectifier,

torque the mounting nuts (in a cross-

tightening pattern) to 6 inch-pounds (.7

Nm). Torque terminals to 26 inch-

pounds (3 Nm). PROCEED TO STEP

7 TO CHECK RELATED COMPO-

NENTS.

7. Inspect main power switch S1 and replace

if faulty. Go to step 8.

8. Test capacitors C1 and C2 and replace both

capacitors if either is faulty.

NOTE: Faulty capacitors could be the reason

for input rectifier failure.

Visually inspect the capacitors for leakage,

damage, etc., and use appropriate test equip-

ment to determine component integrity.

9. Perform the Switch Board Test.

10. After all tests are completed, install the

case wraparound cover.

TROUBLESHOOTING & REPAIR

F-27

F-27

INVERTEC® STT® & STT® II

INPUT RECTIFIER TEST (continued)

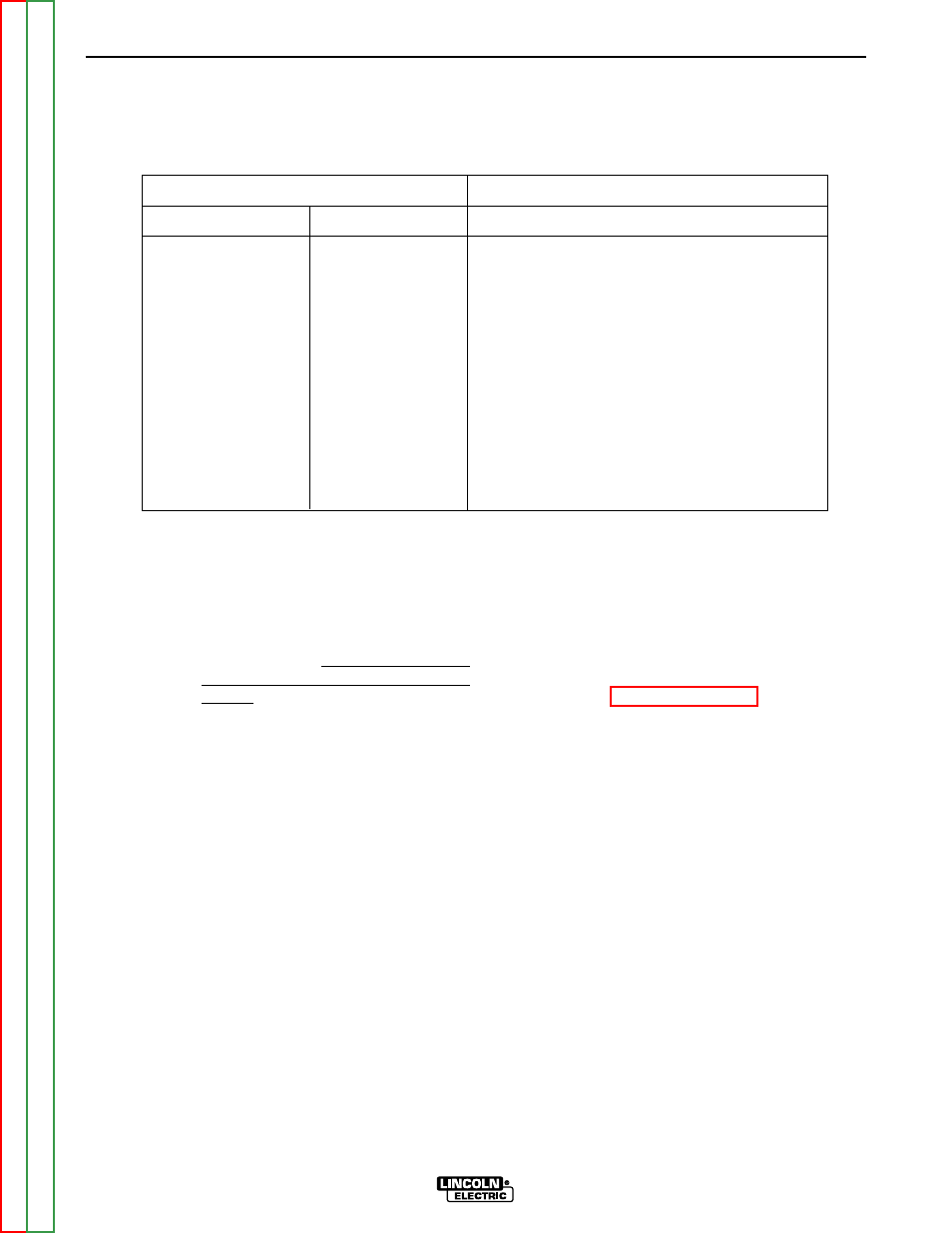

TABLE F.3 – INPUT RECTIFIER TEST

TEST POINTS

+PROBE

-PROBE

ACCEPTABLE METER READING

9

A

Greater than 100K ohms

9

B

Greater than 100K ohms

9

C

Greater than 100K ohms

A

9

Less than 100 ohms

B

9

Less than 100 ohms

C

9

Less than 100 ohms

12

A

Less than 100 ohms

12

B

Less than 100 ohms

12

C

Less than 100 ohms

A

12

Greater than 100K ohms

B

12

Greater than 100K ohms

C

12

Greater than 100K ohms