Electrical diagrams, G-23, Invertec – Lincoln Electric INVERTEC SVM129-B User Manual

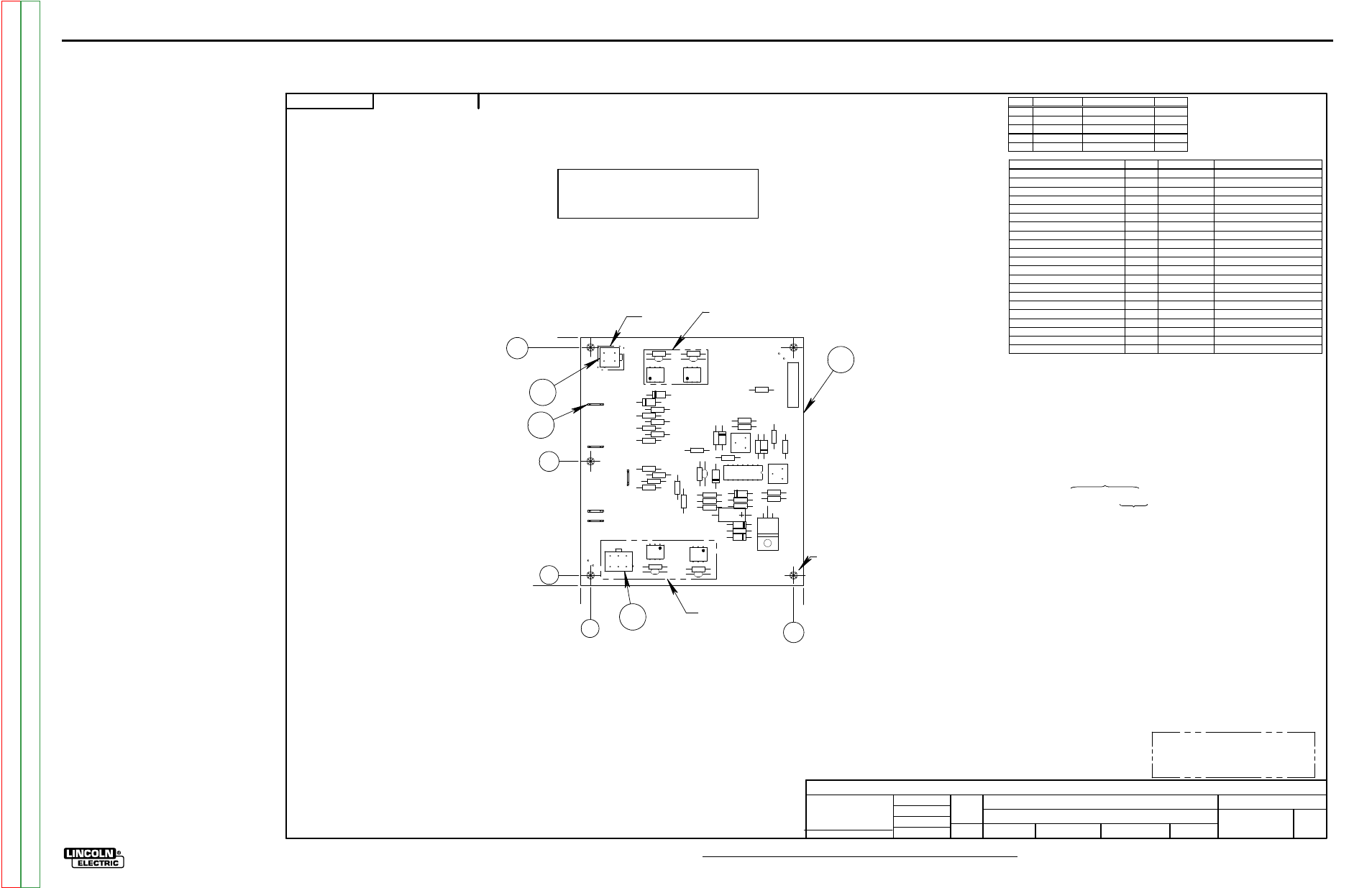

Page 139: Inverter welders protection p.c. board assembly

ELECTriCAL DiAGrAMs

iNvErTEC

®

sTT

®

& sTT

®

ii

PC Board Assembly - Protection - Codes 10151 - 11092 - (L7915)

NOTE:

Lincoln Electric assumes no responsibility for liablilities resulting from board level troubleshooting. PC Board repairs will invalidate your factory warranty. individual Printed Circuit Board Components are not available from Lincoln Electric. This information is provided

for reference only. Lincoln Electric discourages board level troubleshooting and repair since it may compromise the quality of the design and may result in danger to the Machine Operator or Technician. Improper PC board repairs could result in damage to the machine.

G-23

G-23

L7915-3

INVERTER WELDERS

PROTECTION P.C. BOARD ASSEMBLY

1:1

L7915-2

DO NOT SCALE THIS DRAWING

EQUIPMENT TYPE:

SUBJECT:

UF

CRM34409

1

PAGE ___ OF ___

1

ENGINEERING CONTROLLED

MANUFACTURER:

No

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

REVISED MAKE SPECIFICATION

t

MATERIAL TOLERANCE (" ") TO AGREE

WITH PUBLISHED STANDARDS.

ON ALL ANGLES IS ± .5 OF A DEGREE

ON 3 PLACE DECIMALS IS ± .002 in. (± 0.05 mm)

ON 2 PLACE DECIMALS IS ± .02 in. (± 0.5 mm)

UNLESS OTHERWISE SPECIFIED TOLERANCE:

MANUFACTURING TOLERANCE PER E2056

CHANGE DETAIL:

REFERENCE:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

UNITS:

IF PRINTED

@ A2 SIZE

INCH

C

3/16/2007

FEI

-

-

DRAWN BY:

ENGINEER:

CLEVELAND

APPROVED:

CONTROL:

L791

5-3

P.C. BOARD BLANK INFORMATION

MAKE FROM S19399

(MAKES 8 BOARDS PER PANEL; SEE ELECTRONIC FILE

FOR ADDITIONAL INFORMATION)

BLANK PART NUMBER L7915-H

ALL

COMPONENTS AND MATERIALS USED IN THIS

ASSEMBLY ARE TO BE RoHS COMPLIANT PER E4253.

1

2

3

4

.20

2.50

4.80

5.00

.20

4.30

4.50

0

0

±.04

N.A.

N.A.

N.B., N.D.

±.04

N.A.

P

R

O

T

E

C

T

IO

N

5

2

5

3

1

4

H

5

5

1

L

7

9

1

5

-3

R37

R34

R36

R35

R12

R14

R

1

3

R23

R24

R25

R29

R31

R30

R16

R

3

3

R19

R28

R21

R22

R

1

5

R1

R2

R

3

R4

R

9

R

1

0

R8

R27

R6

R5

R

1

1

R32

R26

R18

C

1

C3

C4

C2

DZ1

D8

D7

D

1

D

5

D

4

D6

D3

X1

J

8

J15

R

2

0

R7

X2

C5

C6

OCI1

OCI2

OCI3

OCI4

B

1

4

B

5

1

B

5

2

B

5

3

B

5

NOTES:

N.D. .30 DIA. AREA TO BE FREE OF ENCAPSULATION MATERIAL.

N.A. COVER THIS AREA OF BOARD, TOP AND BOTTOM WITH

ITEM 5 .

N.B. DO NOT COAT WITH ENCAPSULATION.

(5 HOLES, BOTH SIDES OF BOARDS).

FILL SLOT COMPLETELY.

ITEM 5 IS TO FILL AREA BETWEEN

UNDERSIDE OF COMPONENT AND P.C. BOARD WITH NO VOIDS.

MAKE PER E1911-ROHS

TEST PER E2916-PR

ENCAPSULATE WITH E1844

SCHEMATIC REFERENCE: M16097-3H0

FOR PARTS ORDERS:

PERFORM "PARTS ORDERS" TEST

PER E2916-PR2-A

MANUFACTURED AS

IDENTIFICATION CODE

L7915-3H0

ITEM PART NO.

DESCRIPTION

REQ'D

1

SEE BLANK

P.C. BOARD BLANK

1

N.A.

2

S18248-4

HEADER (J8)

1

N.B.

3

T13157-14

TAB TERMINAL

5

N.B.

4

S18248-6

HEADER (J15)

1

5

E2861

SEALANT

10 g

ITEM

REQ'D

PART NO.

DESCRIPTION

C1,C3,C4,C5,C6

5

S16668-5

.022/50

C2

1

S13490-93

27/35

D1,D3,D4,D5,D6,D7

6

T12199-1

IN4004

D8

1

T12199-2

IN4007

DZ1

1

T12702-27

IN4740

OCI 1,OCI 2,OCI 3,OCI 4

4

S15000-22

OPTO ISOLATOR

R1,R2

2

S19400-6813

681K 1/4W

R3,R13,R16

3

S19400-1821

1.82K 1/4W

R4,R5,R11,R12

4

S19400-1503

150K 1/4W

R6,R8,R9,R10,R27

5

S19400-5622

56.2K 1/4W

R7,R20

2

T10812-36

5K 1/2W TRIMMER

R14

1

S19400-1003

100K 1/4W

R15

1

S19400-4750

475 1/4W

R18,R26,R28,R32

4

S19400-1002

10K 1/4W

R19

1

S19400-3321

3.32K 1/4W

R21,R23,R24,R25,R29,R30,R31,R33

8

S19400-1502

15K 1/4W

R22

1

S19400-3323

332K 1/4W

R34,R36

1

S19400-2673

267K 1/4W

R35,R37

2

S19400-3320

332 1/4W

X1

1

S15128-4

IC, LM224, OP-AMP

X2

1

S15128-5

+ 5V REG

CAPACITORS = MFD/VOLTS

RESISTORS = OHMS (1/4 WATT)

UNLESS OTHERWISE SPECIFIED:

INDUCTANCE = HENRY