Sentry Industries 5000 User Manual

Page 55

SMC

sierra monitor corporation

Sentry Instruction Manual - Version 6

CALIBRATION

Page: 49

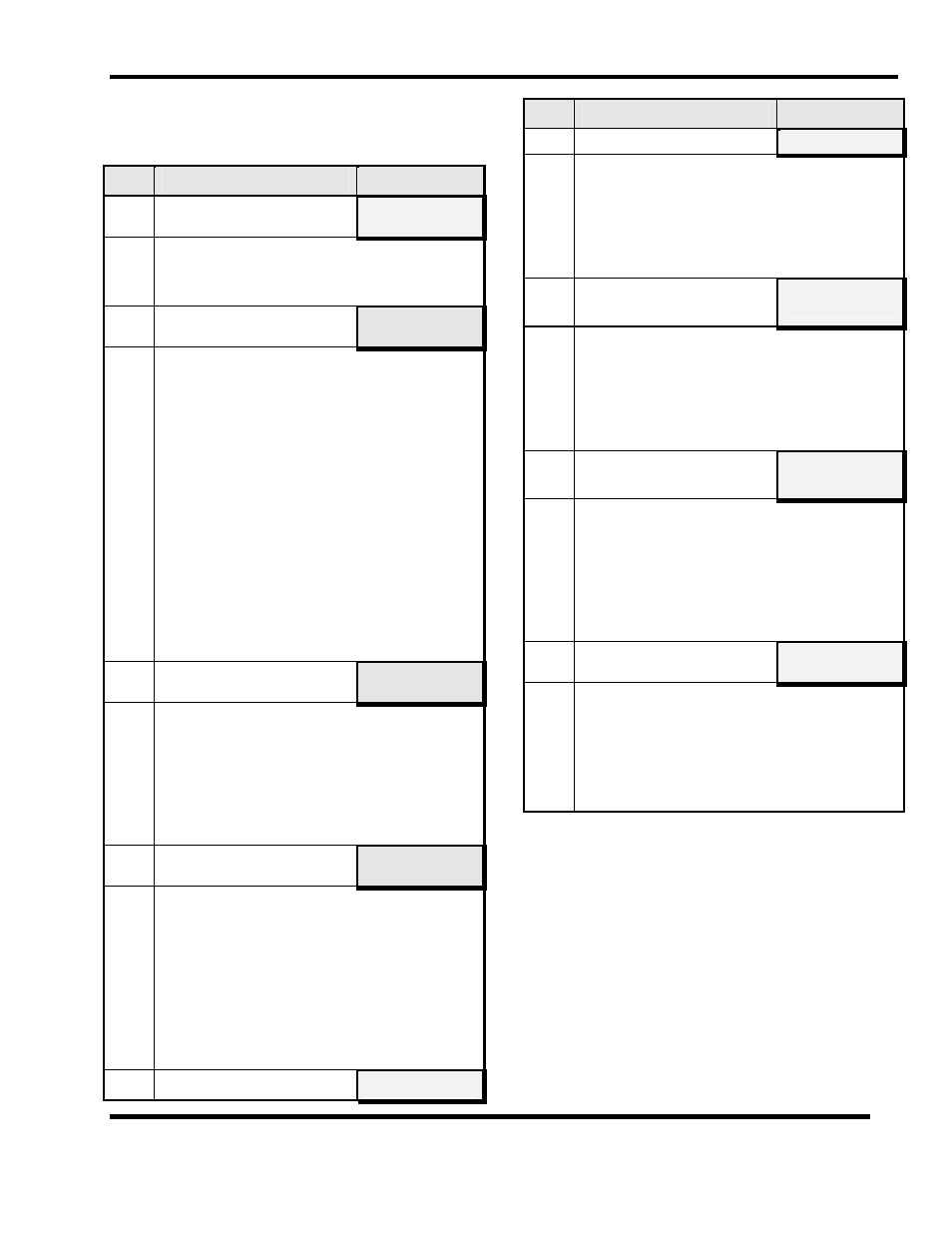

5.3.1.1 GLOBAL CALIBRATION

Proceed with the following steps to perform Global

Calibration.

Step

Activity

Display

1

Begin

ZERO

value read.

ENTER TO ZERO

1 2 3 4 5 6 7 8

Press

ENTER

to start the controller recording the

zero signal value for all modules of the selected

gas type.

2

Complete

ZERO

value read.

APPLY ZERO GAS

ENTER WHEN DONE

The upper display will cycle through all the

applicable module numbers with

"00"

displayed as

the level.

•

Example "1. 00", "2 00" etc.

•

If any module has not been previously

calibrated the "00" will be replaced by a "--".

•

If any sensor is not known to be in clean air at

this time, go to each such sensor which is to be

calibrated and deliver clean air at 100 cc/min

for three minutes using the apparatus in

Section 5.3.2.

Wait until the display cycles through all module

numbers.

Press

ENTER

to complete the zero read and the

display will advance to the span prompt.

3

Begin

SPAN

value read

ENTER TO SPAN

1 2 3 4 5 6 7 8

Press

ENTER

to begin the span process. The top

display begins to cycle through all sensor module

numbers which are configured for the selected

calibration gas. Each module number will show a

"period" immediately after the number and a

numerical concentration display as in the

following example.

[1. 00] [2. 00].

4

Apply

SPAN

gas.

APPLY

50%

LEL

ENTER WHEN DONE

Apply calibration gas to each sensor which is to

be calibrated using the apparatus in Section 5.3.2.

Use magnetic or non magnetic calibration gas

delivery fitting.

During the time calibration gas is being delivered

the upper display on the controller will continue

to cycle through all applicable module numbers.

The module responding to gas will generally show

an increasing reading on each pass.

5

Complete

SPAN

gas

application - no errors

CALIB COMPLETE

PLEASE WAIT

3:00

Step

Activity

Display

application - no errors

PLEASE WAIT

3:00

When all modules have received calibration gas

press

ENTER

to indicate completion of the span

process. If all modules have been successfully

calibrated the controller will begin the three

minute time delay before placing modules back on

line

6

Error Conditions - Low

Sensitivity

LOW SENSITIVITY

1 2 3 4 5 6 7 8

If any modules were missed, or if any sensors

failed to respond correctly to the calibration gas

the low sensitivity message will identify those

sensor module numbers. If calibration of the

module was attempted, note the number and plan

corrective action as described in Section 7.

7

Error conditions - Not

Calibrated

NOT CALIBRATED

1 2 3 4 5 6 7 8

Press

ENTER

again. If all modules have been

successfully calibrated the controller will begin

the three minute time delay before placing

modules back on line. If any modules were

displayed as

LOW

SENSITIVITY

, they will be

displayed again as

NOT CALIBRATED

. Press

ENTER

to acknowledge

8

Return to Operate Mode

PRESS ENTER TO

OPERATE MODE

When the time delay is complete the display will

read

PRESS

ENTER

TO OPERATE

MODE

Press

ENTER

and the procedure is complete. Repeat the

process as necessary to recalibrate modules or to

calibrate other gases.

Remove all calibration apparatus from sensors.