Support.bearing. adjustment, Notice – Woodstock SHOP FOX M1113 User Manual

Page 22

-20-

Model M1113 (Mfg. Since 2/08)

SE

TU

P

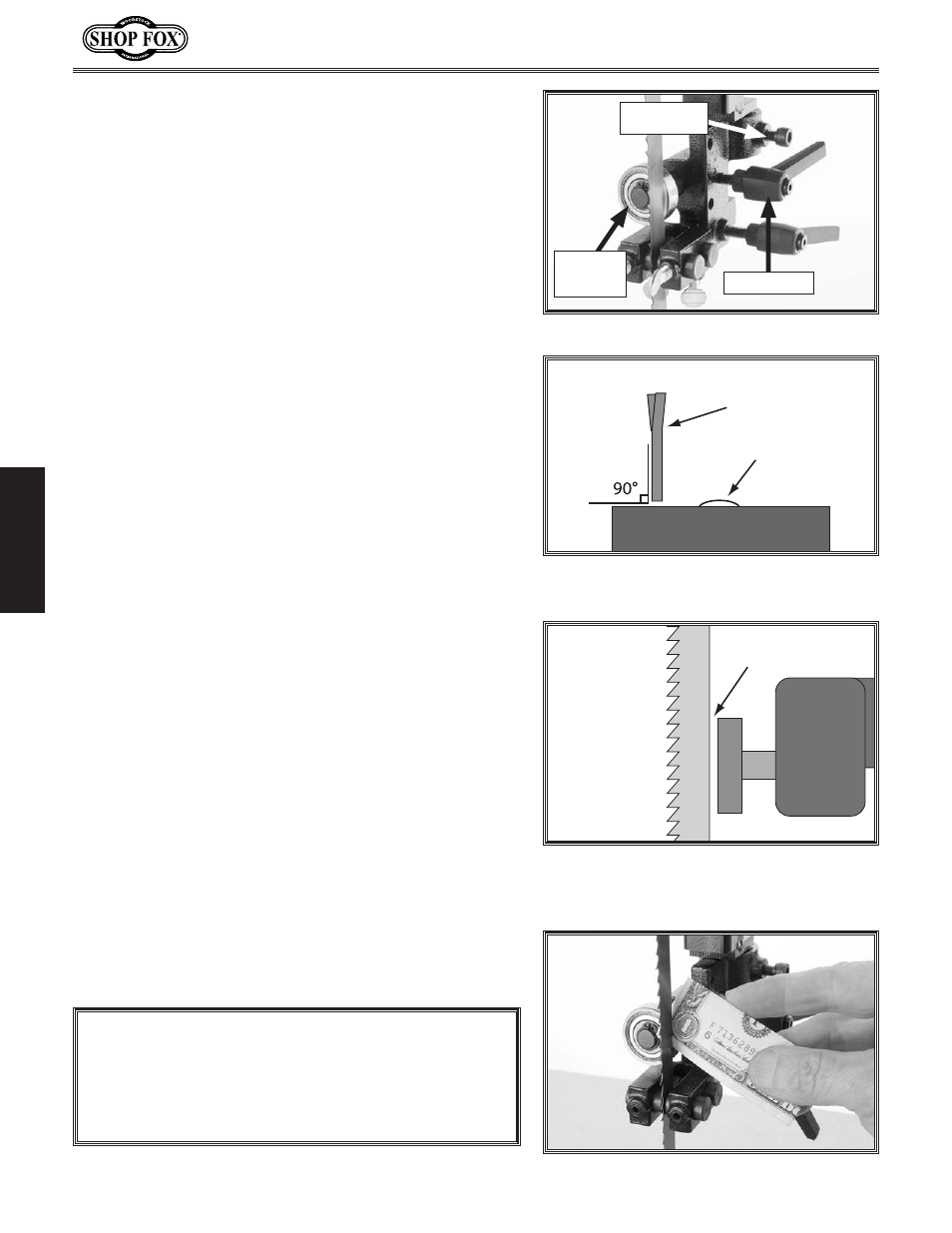

The support bearings are positioned behind the blade for

support during cutting operations. Proper adjustment of

the support bearings is an important part of making accu-

rate cuts and also keeps the blade teeth from hitting the

blade guides during cuts.

To.adjust.the.support.bearings,.do.these.steps:

1. Make sure that the blade is tracking properly and

that it is correctly tensioned.

2.. DISCONNECT BANDSAW FROM POWER!

3. Familiarize yourself with the support bearing con-

trols shown in

Figure.24.

4.. Remove the blade guard.

5. Loosen the cap screw shown in Figure.24.

6. Look at the face of the support bearing and rotate

the blade guide assembly side-to-side, until the

blade is perpendicular with the face of the support

bearing, as illustrated in

Figure.25.

7. Tighten the cap screw.

8. Loosen the lock lever on the support bearing adjust-

ment shaft.

9. Position the support bearing approximately 0.016"

away from the back of the blade as illustrated in

Figure.26. To quickly gauge this setting, fold a dol-

lar bill in half twice (when folded tightly, four thick-

nesses of a dollar bill is approximately 0.016"). Place

the folded dollar bill between the support bearing

and the blade as shown in

Figure.27.

10. Tighten the lock lever to lock the support bearing in

place.

Support.Bearing.

Adjustment

Figure.24. Support bearing controls.

Bandsaw

Blade

Support

Bearing

Figure.25. Blade should be perpendicular

(90˚) to the face of the support bearing.

0.016''

Figure.26. Blade should be aligned

approximately 0.016" away from the

bearing edge.

Figure.27. Dollar bill folded twice to make

a quick 0.016" gauge.

NOTICE

Whenever.changing.a.blade.or.adjusting.tension.and.

tracking,.the.upper.and.lower.blade.support.bearings.

and.guide-blocks.must.be.re-adjusted.before.cutting.

operations..

Lock Lever

Support

Bearing

Cap Screw