1 advancedtca* reference heatsink, 1 thermal performance, 2 mechanical design envelope – Intel WiFi Link 5100 User Manual

Page 25: Advancedtca* reference heatsink 6.1.1, Thermal performance, Mechanical design envelope

Intel

®

5100 Memory Controller Hub Chipset for Communications, Embedded, and Storage Applications

July 2008

TDG

Order Number: 318676-003US

25

Intel

®

5100 MCH Chipset

The Intel

®

5100 MCH Chipset has a lower TDP than the Intel

®

5000 Series Chipset and

a similar package size. Due to this, any thermal solutions for the Intel

®

5000 Series

Chipset should be reusable for the Intel

®

5100 MCH Chipset including the Intel

reference solutions. The system designer still needs to verify that the entire thermal

solution will meet the component temperature specifications and TDP in the intended

system.

6.1

AdvancedTCA* Reference Heatsink

6.1.1

Thermal Performance

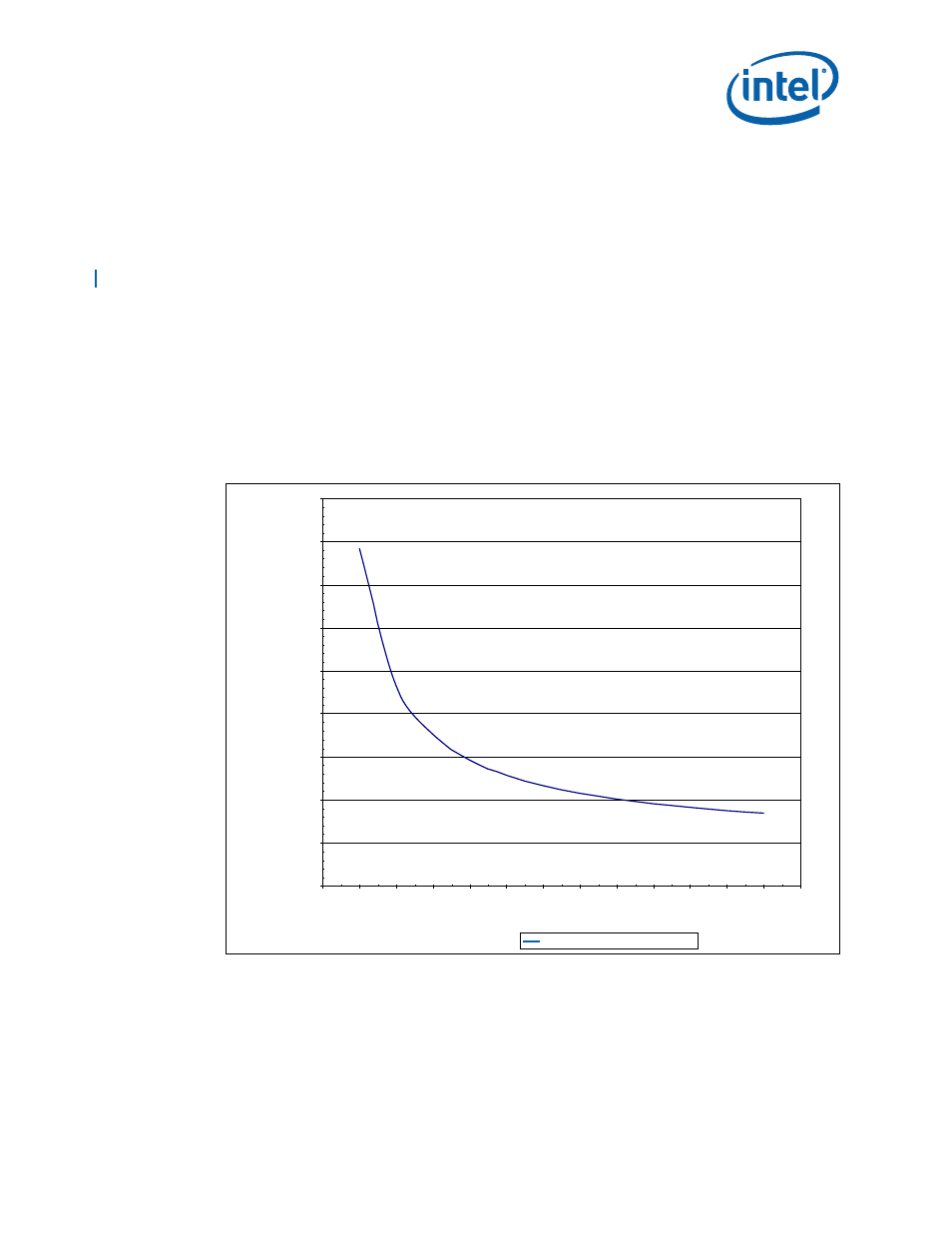

The AdvancedTCA* reference heatsink should be made from aluminum to achieve the

necessary thermal performance. Depending on the boundary conditions, the reference

heatsink can meet the thermal performance needed to cool the Intel

®

5100 MCH

Chipset in the AdvancedTCA* form factor. The heatsink performance versus airflow

velocity is shown in

. The heatsink may be used in other form factors that can

provide the required amount of airflow to meet the components thermal specifications.

6.1.2

Mechanical Design Envelope

While each design may have unique mechanical volume and height restrictions or

implementation requirements, the height, width, and depth constraints typically placed

on the Intel

®

5100 MCH Chipset thermal solution are shown in

.

Figure 18.

Torsional Clip Heatsink Measured Thermal Performance versus Approach

Velocity

0.000

0.500

1.000

1.500

2.000

2.500

3.000

3.500

4.000

4.500

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

Airflow Approach Velocity (LFM)

C

ase

-to

-A

m

b

ie

n

t Th

e

rm

a

l C

h

a

rac

ter

iz

a

ti

on

P

a

ra

m

e

te

r,

Ψ

CA

(°

C

/W

)

ATCA Heatsink

AdvancedTCA* Heatsink