Ingersoll-Rand 66M2X0-XXX-C User Manual

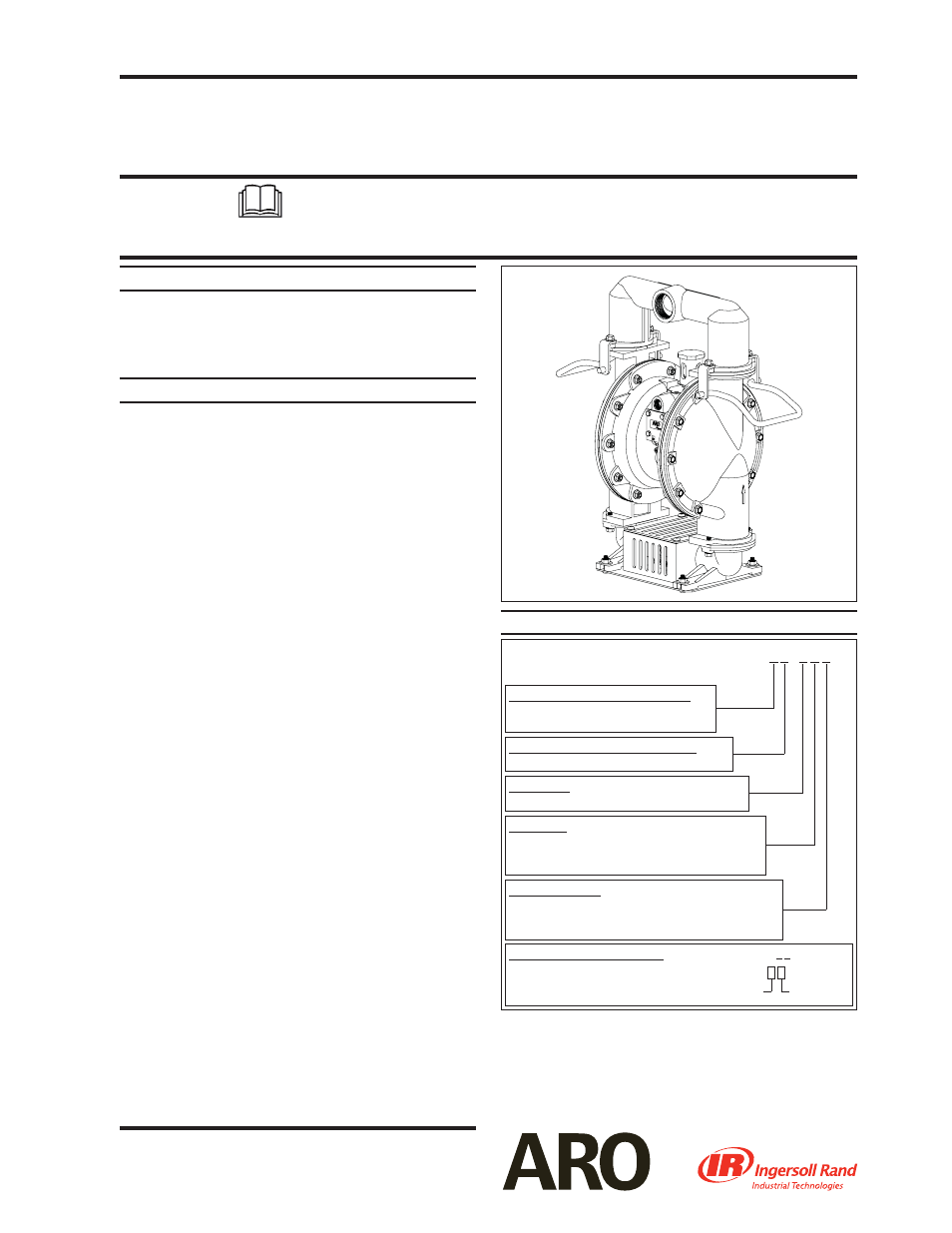

Operator’s manual 66m2x0-xxx-c, 2" diaphragm pump

INGERSOLL RAND COMPANY LTD

P.O. BOX 151

y ONE ARO CENTER y BRYAN, OHIO 43506-0151

(800) 276-4658

y

FAX (800) 266-7016

© 2009

CCN 15321508

fl uids.ingersollrand.com

OPERATOR’S MANUAL

66M2X0-XXX-C

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

RELEASED: 10-22-08

REVISED: 2-16-09

(REV. 03)

2" DIAPHRAGM PUMP

1:1 RATIO (METALLIC)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

The original language of this manual is English.

SERVICE KITS

Refer to Model Description Chart to match the pump material op-

tions.

637434 for air section repair (see page 6).

637468-XX for fl uid section repair (see page 4).

PUMP DATA

Models . . . . . . . . . . . . . . . . . see Model Description Chart for “-XXX”

Pump Type . . . . . . . . . . . . . Metallic Air Operated Double Diaphragm

Material . . . . . . . . . . . . . . . . see Model Description Chart

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.15 lbs (33.63 kgs)

Maximum Air Inlet Pressure . . . . . . . . . . . 120 p.s.i.g. (8.3 bar)

Maximum Material Inlet Pressure . . . . . . 10 p.s.i.g. (0.69 bar)

Maximum Outlet Pressure . . . . . . . . . . . . . 120 p.s.i.g. (8.3 bar)

Maximum Flow Rate (fl ooded inlet) . . . 156 g.p.m. (590.5 l.p.m.)

Displacement / Cycle @ 100 p.s.i.g. . . . . 1.02 gal. (3.86 lit.)

Maximum Particle Size . . . . . . . . . . . . . . . . 3/4” dia. (19.1 mm)

Maximum Temperature Limits (diaphragm / ball / seal material)

E.P.R. / EPDM . . . . . . . . . . . . . . . . . . . -60° to 280° F (-51° to 138° C)

Hytrel® . . . . . . . . . . . . . . . . . . . . . . . . . -20° to 150° F (-29° to 66° C)

Nitrile . . . . . . . . . . . . . . . . . . . . . . . . . . 10° to 180° F (-12° to 82° C)

Santoprene® . . . . . . . . . . . . . . . . . . . -40° to 225° F (-40° to 107° C)

Viton® . . . . . . . . . . . . . . . . . . . . . . . . . . -40° to 350° F (-40° to 177° C)

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . see page 8

Noise Level @ 70 p.s.i., 60 c.p.m.

c . . . . . . 85.3 db(A)d

Noise Level @ 70 p.s.i., 60 c.p.m.

e . . . . . . 105.3 db(A)d

c Tested with 94810 muffl er assembly installed.

d The pump sound pressure levels published here have been updated to

an Equivalent Continuous Sound Level (L

Aeq

) to meet the intent of ANSI

S1.13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

e Tested with 97116 housing and 97110-2 ball installed. Hearing protec-

tion is recommended when operating this product.

NOTICE: All possible options are shown in the chart, however, certain

combinations may not be recommended, consult a representative or

the factory if you have questions concerning availability.

Figure 1

MODEL DESCRIPTION CHART

66M2 X 0 - X X X - C

Center Body Material / Fluid Connection

5 - Aluminum / 2 - 11-1/2 NPTF - 2

7 - Aluminum / Rp 2 (2 - 11 BSP parallel)

Ball Material

2 - Nitrile

C - Hytrel

E - Santoprene

Example: Model #66M250-1EB-C

Fluid Section Service Kit # 637468-EB

66M2X0 - X X X - C

Ball Diaphragm

637468 - X X

Fluid Cap & Manifold Material / Hardware

0 - Aluminum / Carbon steel

Diaphragm Material

2 - Nitrile

9 - Hytrel

B - Santoprene

Seat Material

1 - Aluminum

Fluid Section Service Kit Selection

Document Outline

- Service Kits

- Pump Data

- Model Description Chart

- Operating and Safety Precautions

- General Description

- Air and Lube Requirements

- Operating Instructions

- Maintenance

- Fluid Section Disassembly

- Fluid Section Reassembly

- Fluid Section Parts List

- Fluid Section Parts List View

- Air Motor Section Parts List

- Air Motor Section Service

- Pilot Valve Disassembly

- Pilot Valve Reassembly

- Major Valve Disassembly

- Major Valve Reassembly

- Air Motor Section Parts List View

- Trouble Shooting

- Dimensional Data