Ingersoll-Rand ARO 650542-1 User Manual

Pump system, Service kits, General description

INGERSOLL RAND COMPANY LTD

P.O. BOX 151

y ONE ARO CENTER y BRYAN, OHIO 43506-0151

(800) 276-4658

y

FAX (800) 266-7016

© 2008

CCN 99652174

fl uids.ingersollrand.com

OPERATOR’S MANUAL

650542-X

650543-X

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE.

INCLUDE MANUALS: 6712X-X Pump (pn 97999-602), 651615-X-D Single Post Lift / Ram (pn

97999-1025) & S-636 General Information (pn 97999-636).

RELEASED: 3-6-95

REVISED: 3-17-08

(REV. H)

650542-X

650543-1

Carbon Steel

Stainless Steel

Pump System

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

4-1/4” AIR MOTOR

43.6:1 RATIO

4” STROKE

SERVICE KITS

Use only genuine ARO® replacement parts to assure compat-

ible pressure rating and longest service life.

61268 for repair of 65440 air motor section.

104158 for repair of 127112-000 regulator.

104176 for repair of F25241-100 fi lter.

104177 for repair of R27241-100 regulator

116772 for repair of E512LM valve.

637290-P43 for repair of 67100-P43 lower pump section.

637291-P43 for repair of 67101-P43 lower pump section.

GENERAL DESCRIPTION

WARNING

DO NOT EXCEED MAXIMUM OPERATING

PRESSURE OF 6,549 P.S.I. (451.7 BAR) AT 150 P.S.I. (10.3

BAR) AIR INLET PRESSURE.

WARNING

REFER TO GENERAL INFORMATION MANUAL

INCLUDED FOR OPERATING AND SAFETY PRECAU-

TIONS AND OTHER IMPORTANT INFORMATION.

By delivering a smooth, continuous bead of the proper size,

an ARO system helps the operator maintain both production

rate and produce high quality standards. Maintained quality

standards assures that the material benefi ts are realized. To

further maximize operator production time, the ARO sys-

tem has a built-in lift / ram feature for quick and easy drum

changeover and easy lifting of the pump assembly from the

container.

ARO systems are totally enclosed, sealing the material in the

system from air and moisture, preventing premature cure-

out of the material. This allows for either continuous or in-

termittent use of the system and reduces the need for daily

system clean-up.

The 43.6:1 ratio is an expression of the relationship between

the effective air motor area and the effective lower pump

area. When 150 p.s.i. (10.3 bar) of air pressure is supplied to

the air motor, the lower pump area will develop a maximum

of 6,549 p.s.i. (451.7 bar) of fl uid pressure (at no fl ow). As the

fl uid control is opened, the fl ow rate will increase as the air

motor cycle rate increases to keep up with the demand.

3

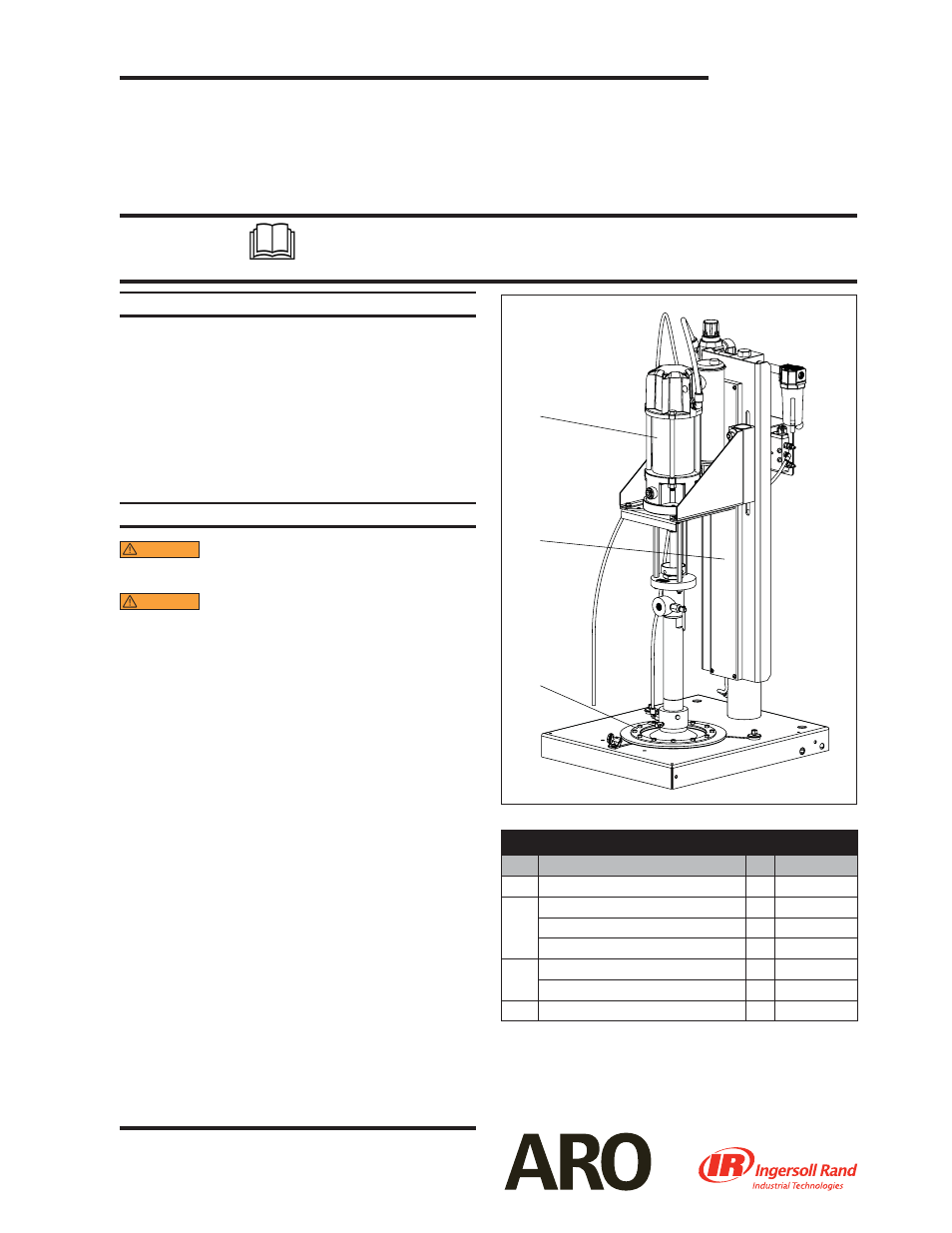

1

2

Figure

1

MAJOR COMPONENTS

Item Description

(size)

Qty Part No.

1 Single Post Ram Assembly

(1) 651615-D

2 Follower Plate

(model 650542-1)

(1) 651840-1

(model 650542-2)

(1) 651840-2

(model 650543-1)

(1) 651841-1

3 Basic Pump Assembly

(model 650542-X)

(1) 67120-P43

(model 650543-1)

(1) 67121-P43

Portability Kit

(optional) (not shown)

66713

y ARO® is a registered trademark of Ingersoll-Rand Company y