4 grounding procedures, 1) grounding methods, 2) grounding procedures – MITSUBISHI ELECTRIC Mitsubishi Industrial Robot RV-6S User Manual

Page 19: 4 grounding procedures -9, Caution

2Unpacking to Installation

Installation 2-9

2.2.4 Grounding procedures

(1) Grounding methods

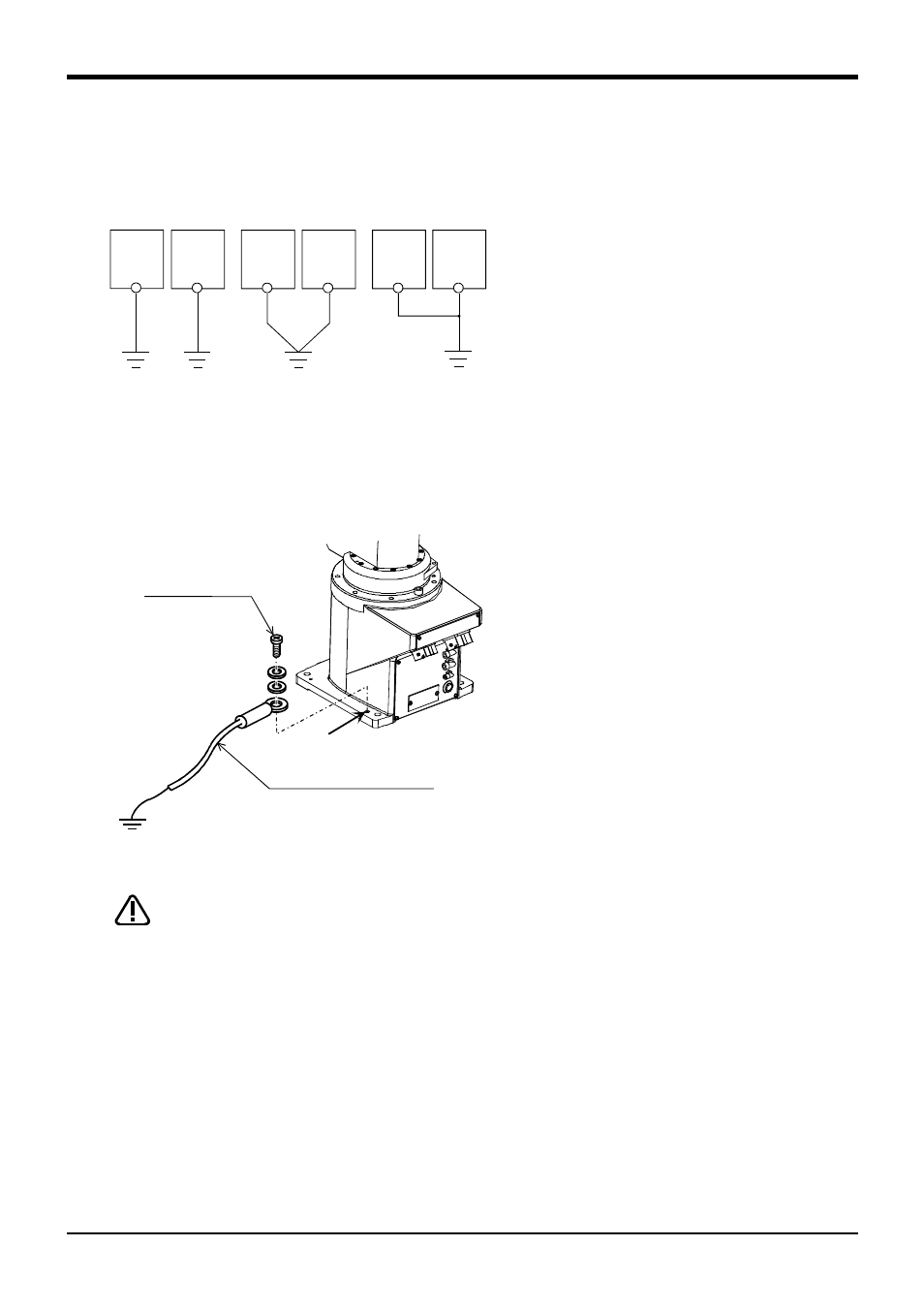

1) There are three grounding methods as shown in

, but the dedicated grounding (

)

should be used for the robot arm and controller

when possible. (Refer to the separate " Controller

Setup, Basic Operation and Maintenance" for

details on the controller grounding.)

2) Use Class D grounding (grounding resistance

100Ω or less).

Dedicated grounding separated from the other

devices should be used.

3) Use a AWG#11(3.5mm

2

) or more stranded wire for

the grounding wire. The grounding point should be

as close to the robot arm and controller as possi

-

ble, and the length of the grounding wire should

be short.

Fig.2-4 : Grounding methods

(2) Grounding procedures

1) Prepare the grounding cable (AWG#11(3.5mm

2

)

or more) and robot side installation screw and

washer.

2) If there is rust or paint on the grounding screw

section (A), remove it with a file, etc.

3) Connect the grounding cable to the grounding

screw section.

Fig.2-5 : Connecting the grounding cable

When installing the robot, be sure to allocate a sufficient maintenance space for

connecting the cables between devices and replacing a backup battery at the rear

of the robot.

Robot arm

Controller

and

personal

computer

(a) Dedicated grounding

(Optimum)

(b) Common grounding

(Good)

(c) Common grounding

(Normal)

Robot arm

Controller

and

personal

computer

Robot arm

Controller

and

personal

computer

M4×10, SW, PW

Robot arm

A

Robot grounding cable

(AWG#11 (3.5mm

2

) or more)

(Prepared by customer)

CAUTION