Refrigerant piping. 4, Good example, Bad example – MITSUBISHI ELECTRIC PE-15MYC User Manual

Page 96

- 95 -

Extension piping and installation parts are field supply.

Perform the work only after carefully reading the

appropriate instructions.

Install the unit where the refrigerant piping is shortest,

the difference between the indoor unit and outdoor unit

is smallest.

As pipes purchased in the market may contain

dust, below them off with dry inlet gas.

Take care not to allow dust and water content to enter

the piping during pipe processing or installing.

Minimize the number of bends, and make the bending

radius as long as possible.

Always observe the restriction(allowable length, height

difference, pipe diameter) on the refrigerant piping.

For soldering & brazing, use high-quality materials.

Never purge air with a refrigerant. Always use a vacuum pump for purging.

Provide proper insulation to the piping . Insufficient insulation cause poor cooling/heating

performance or condensation drip, leading to unexpected trouble.

Do not insulate gas or low pressure pipe and liquid or high pressure pipe together.

For the connection of the refrigerant piping, leave the valve of the outdoor unit fully closed

(as set before shipment), and no operate it until the connection between the indoor/outdoor

units and refrigerant piping, refrigerant leak test and evacuation work have been completed.

The maximum permissible values are shown below.

Remove the cover (grommet) attached sheet metal at exit of heat exchanger pipe of indoor

unit before connecting the local piping.

(This cover is protect the pipe from sheet metal edge at unit transportation.)

Please insulate liquid pipe & gas pipe (two places for each) with an insulated pipe of the

attachment after connecting piping.

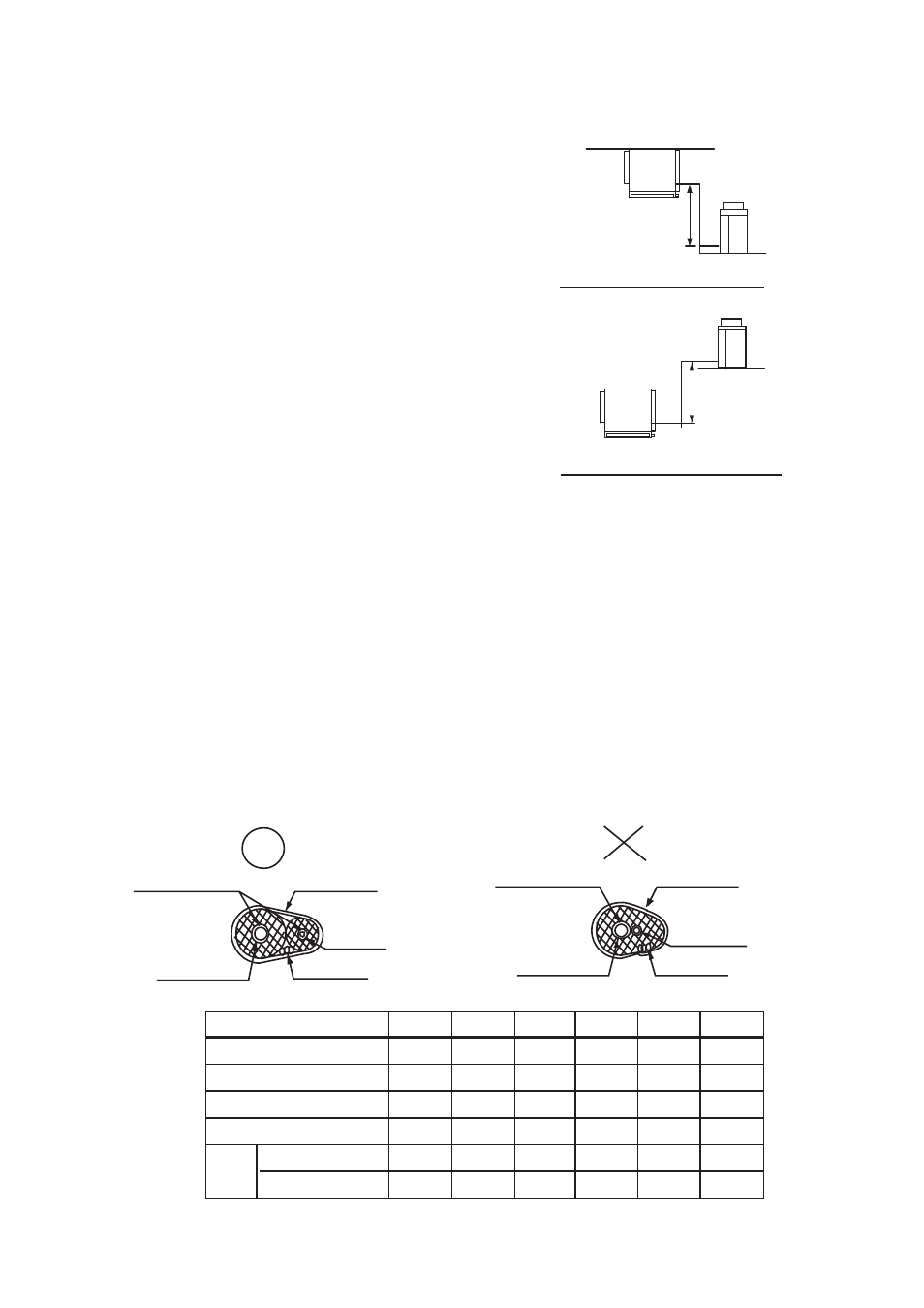

Finishing tape

Gas pipe

Insulating material

Liquid pipe

Good example

Electric wire

Electric wire

Finishing tape

Gas pipe

Insulating material

Liquid pipe

Bad example

Refrigerant piping.

4.

A

B

When the outdoor unit is lower.

When the outdoor unit is higher.

Dimension A (m)

Dimension B (m)

Number of bends

Total piping length (m)

Piping

Liquid pipe (mm)

size

Gas pipe (mm)

PEH-5

12.7

PE(H)-7 PE(H)-8 PE(H)-10

20

30

15

50

15.88

50

19.05

20

30

15

50

25.4

15.88

20

30

15

25.4

50

20

30

15

PE(H)-15

50

20

30

15

2x25.4

2x15.88

PE(H)-20

50

20

30

15

2x28.6

15.88

28.6

2x15.88