MITSUBISHI ELECTRIC PE-15MYC User Manual

Page 7

- 6-

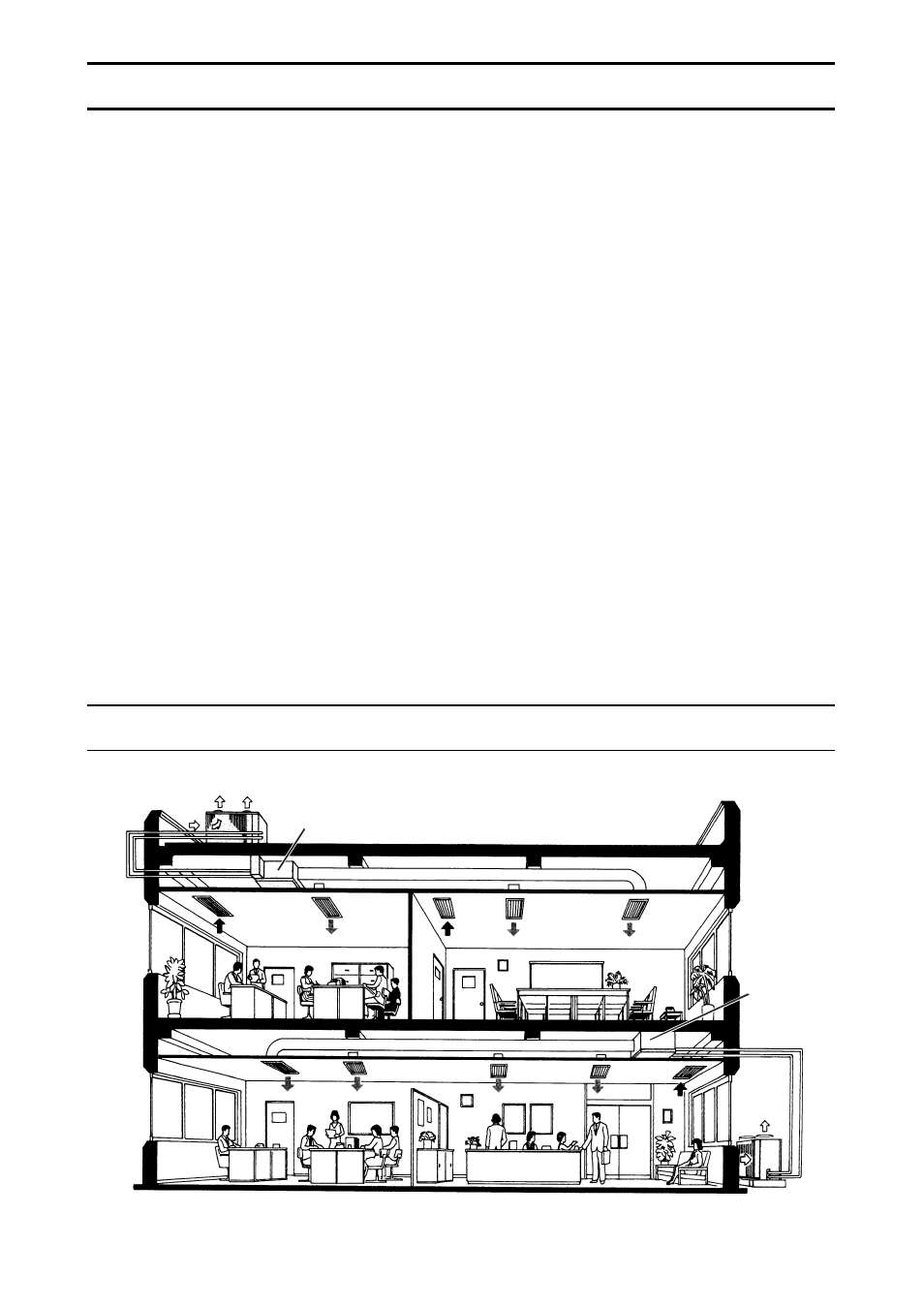

TYPICAL INSTALLATION EXAMPLE

MECHANICAL SPECIFICATIONS

General

All units are factory assembled, piped, internally wired.

They are also tested and checked under a strict quality

control system in the factory.

Exterior surfaces of all units of outdoor unit are

phosphatized, zinc-coated steel with powder coating

and ivory white baked enamel finish.

Refrigeration Controls

Refrigeration controls include condenser fan,

evaporator fan and compressor contactors.

Compressors

All units have high efficiency type hermetic line starting

compressors.

Compressors are equipped with thermal overload

protector, over-current relay and high pressure

protection control.

Crankcase heaters are standard.

Evaporator Coils

Highly efficient cross-finned coil are applied to provide a

larger cooling capacity with low air speed on the coil.

Coils are made of 9.52mm OD and 0.35mm thick

seamless copper tubing mechanically bonded to 0.12mm

thick aluminium fins and are factory leak tested at a

pressure of 3.3MPa. They are provided with strainers

attached to the capillary tubes to further ensure a clean

system.

Condenser Coils

Unnecessary power input due to higher discharge

pressure is avoided by high performance designs of

cross-finned coil.

Condenser coils are made of 9.52mm OD, 0.35mm

thick seamless copper tubes mechanically bonded to

0. 12mm thick aluminium fins and factory pressure

and leak tested at 3.3MPa.

Evaporator Fans

The sirocco fans are made of galvanised steel and

balanced to proved accurate air flow performance at

low noise level.

Condenser Fan

The direct-drive propeller fan is dynamically balanced,

to ensure smooth airflow.

A weatherproof three-phase squirrel cage induction

motor is used to drive the condenser fan.

PU(H)

PE(H)

PE(H)

PU(H)