Section 5 installation, Arial installation, Installation – Motorola BT100 User Manual

Page 44: Aerial installation

BT100 Installation and Operation Manual

Section 5

Installation

The field installation procedures presented in the following subsections assume that the

amplifier was previously tested and bench aligned. Cable power and RF signal must be

available on the system. Although it is preferable to have a full complement of channels

available for balancing, you can adjust the BT100 adequately with a limited number of

channels.

You can install the BT100 housing on a messenger strand (aerial) or on a pedestal. The

following subsections provide details on each application.

Aerial Installation

The housing is normally mounted horizontally below the strand, with the electronics chassis

removed, to avoid possible damage during installation. Connections are made using standard

pin-type connectors with a nominal center-conductor diameter of 0.067 inches. The minimum

length of the center-conductor pin is 1.5 inches and the maximum length is 1.65 inches. Longer

pins can extend past the center-conductor seizure mechanism and degrade the match.

Extremely long pins can result in a short circuit.

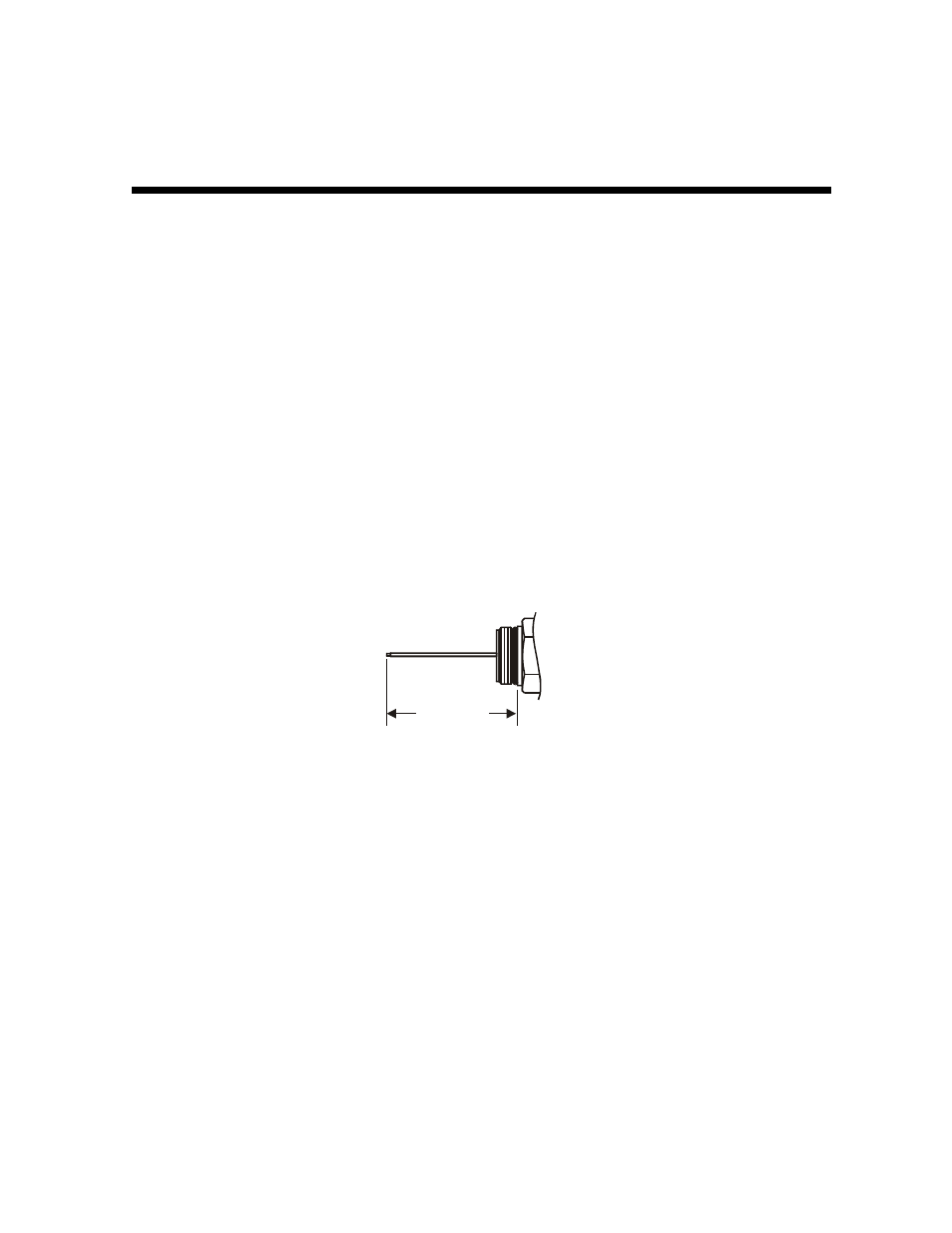

Figure 5-1

Center-conductor pin length

1.65" Max.

1.50" Min.

To install the unit:

1

Power down the cable before you install the housing. This avoids blown fuses, tripped circuit

breakers, and possible personal injury.

2

Mount the housing, and torque the two 5/16-inch messenger clamp bolts, located on the long

sides of the housing (illustrated in Figures 2-5 and 2-7) to 12 ft-lbs.

3

Form the customary expansion loops and make all cable connections according to system

design.

4

Tighten the center-conductor seizure screw using a Phillips-head screw driver. An

alternative method is to use a 3/16-inch socket and a torque wrench. The recommended

torque is 12 in-lbs. maximum.

5

To avoid water ingress, ensure that aluminum connectors are torqued to the specifications

recommended by the connector manufacturer.

6

If previously removed, re-install the electronics chassis and fasten it to the housing with the

six captive bolts. Torque to 18 to 22 in-lbs.

7

Remove the input pad (JXP IN) to avoid damage to the hybrids.