Section 4 bench testing, Test equipment and connections, Bench testing – Motorola BT100 User Manual

Page 40: Before you begin

BT100 Installation and Operation Manual

Section 4

Bench Testing

Motorola’s recommended procedure for placing a new BT100 into service is to fully test it on the

bench before it is installed. There are specific alignment procedures that ensure proper

functioning of all components and simplify final installation. If the BT100 is properly aligned on

the bench, only minor adjustments may be required in the field.

The following subsections provide instructions to bench align the BT100.

Before You Begin

The BT100 is shipped with a 20 ampere blade-type fuse in each active port for over current

protection.

CAUTION!

To avoid applying 60/90 Vac to the test equipment during testing, remove the fuse from the connected output port F2,

F3, F4 or F5 (illustrated in Figure 2-9). Terminate all unused ports.

Open the housing and remove the electronics chassis cover. Refer to your system drawings or

records to confirm the presence of the required options as described in Section 2, “Overview,”

Options and Accessories.

Reinstall the electronics chassis cover and torque the screws to 10–12 in-lbs.

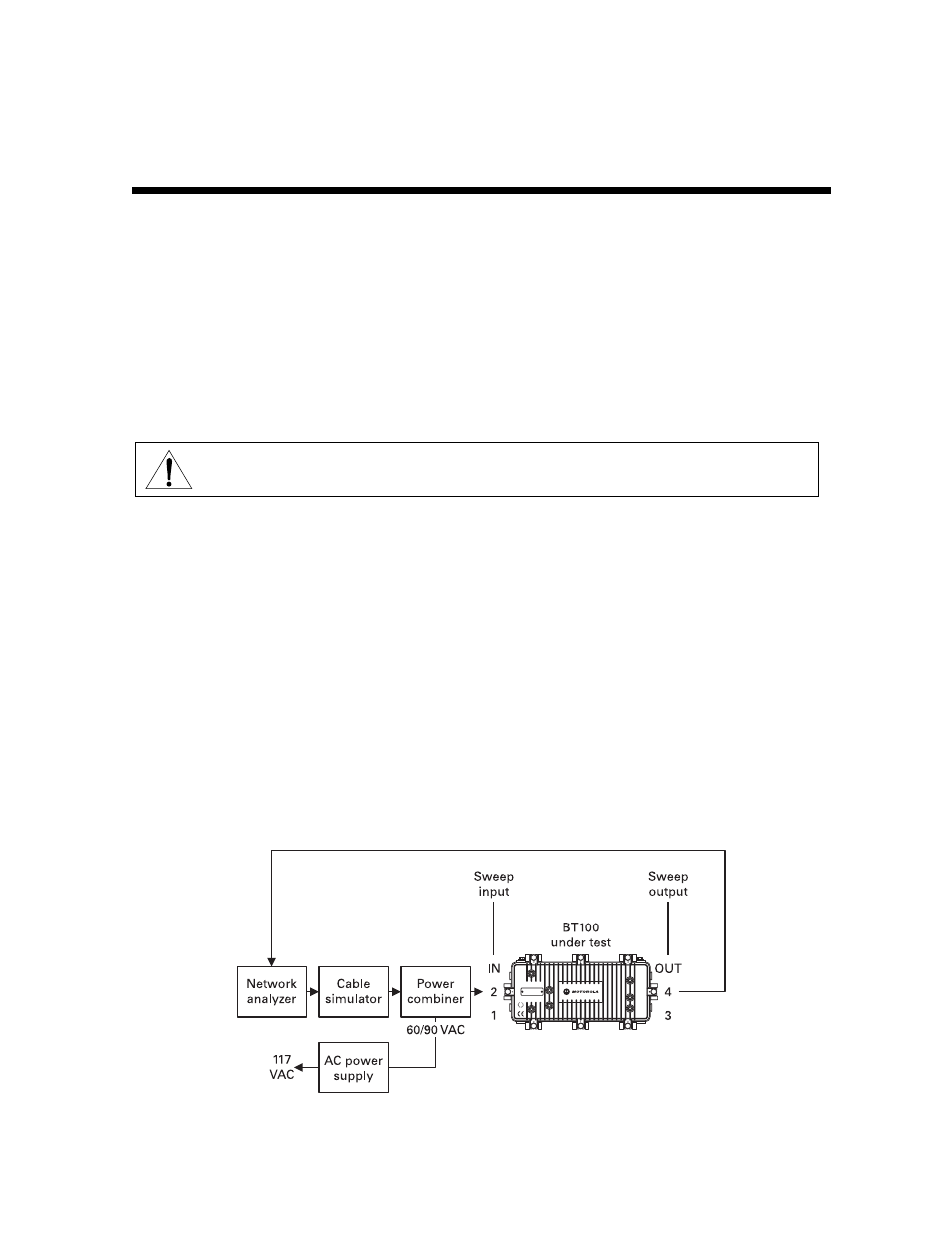

Test Equipment and Connections

The equipment typically used for testing the BT100 consists of a network analyzer, such as the

HP8712 or 8713 series, a 60/90 VAC bench power supply, a cable simulator, a Motorola model

SSP-PIN power combiner, and a variety of jumper cables, adapters, and fittings.

Fabricate a cable simulator that you can configure to provide the desired cable loss in 1 dB

increments, up to approximately 30 dB. Then, connect the test equipment as shown in

Figure 4-1:

Figure 4-1

Test equipment connections for bench sweeping