Graco Inc. 1095 HI User Manual

Page 12

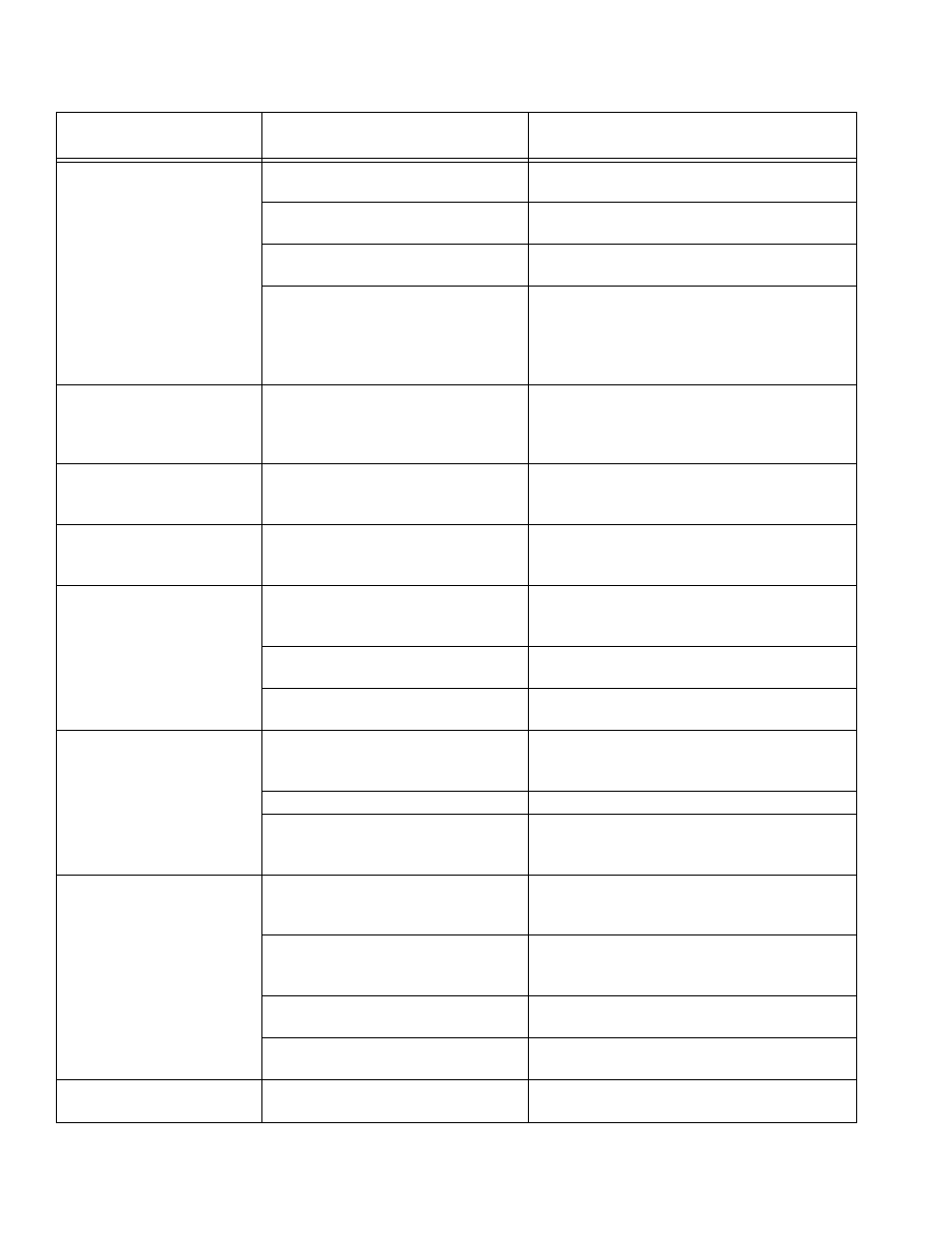

Troubleshooting

12

311365G

Pump output is low

14. O-ring in pump is worn or dam-

aged

14. Replace o-ring; see pump manual 310643

or 310894.

15. Intake valve ball is packed with

material

15. Clean intake valve; see pump manual

310643 or 310894.

16. Pressure setting is too low

16. Increase pressure; see pump manual

310643 or 310894.

17. Large pressure drop in hose with

heavy materials

17. Use larger diameter hose and/or reduce

overall length of hose. Use of more than

100 ft of 1/4 in. hose significantly reduces

performance of sprayer. Use 3/8 in. hose

for optimum performance (50 ft minimum).

Motor runs but pump does

not stroke

1.

Displacement pump pin (32)

damaged or missing; see pump

manual 310643 or 310894.

1.

Replace pump pin if missing. Be sure

retainer spring (31) is fully in groove all

around connecting rod; see pump manual

310643 or 310894.

2.

Connecting rod assembly (43)

damaged; see pump manual

310643 or 310894.

2.

Replace connecting rod assembly; see

pump manual 310643 or 310894.

3.

Gears or drive housing damaged,

page 30.

3.

Inspect drive housing assembly and gears

for damage and replace if necessary; see

pump manual 310643 or 310894.

Excessive paint leakage into

throat packing nut

1.

Throat packing nut is loose

1.

Remove throat packing nut spacer.

Tighten throat packing nut just enough to

stop leakage.

2.

Throat packings are worn or

damaged

2.

Replace packings; see pump manual

310643 or 310894.

3.

Displacement rod is worn or

damaged

3.

Replace rod; see pump manual 310643 or

310894.

Fluid is spitting from gun

1.

Air in pump or hose

1.

Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

2.

Tip is partially clogged

2.

Clear tip; see tip guard manual 309640.

3.

Fluid supply is low or empty

3.

Refill fluid supply. Prime pump; see pump

manual 310643 or 310894. Check fluid

supply often to prevent running pump dry.

Pump is difficult to prime

1.

Air in pump or hose

1.

Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

2.

Intake valve is leaking

2.

Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well.

Reassemble valve.

3.

Pump packings are worn

3.

Replace pump packings; see pump man-

ual 310643 or 310894.

4.

Paint is too thick

4.

Thin the paint according to the supplier’s

recommendations.

No display, sprayer operates 1.

Display is damaged or has bad

connection

1.

Check connections. Replace display.

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK, refer to this column