Adjusting/replacing cutterhead knives, Air pressure torque wrench – Grizzly Extren Series Jointer g9860 User Manual

Page 41

Extreme series Jointer (Mfg. since 9/11)

-39-

adjusting/Replacing

cutterhead Knives

if your jointer has a knife-style cutterhead, cor-

rectly setting the height of the knives is crucial

to the proper operation of the jointer and is very

important in keeping the knives sharp. if one knife

is higher than the others, it will do the majority

of the work, and thus, dull much faster than the

others.

there are several methods for setting the knives.

the Jointer pal

®

included with your jointer is

simple to use and is designed to hold the knives

at the correct setting while you secure them. if you

choose to use the Jointer pal

®

, follow the instruc-

tions that are included with it.

the straightedge method is described below

and produces the same results as the Jointer

pal

®

. this method uses a high-quality, precision

straightedge held flat against the outfeed table

and over the cutterhead, then the knife heights

are set to the bottom of the straightedge, as

shown in

Figure 60.

7. position the straightedge on the outfeed table

and over the insert to make sure that it is

installed correctly and at the same height as

the other inserts.

— if the insert is raised above the correct

height, remove it and repeat the above

procedure until it is properly installed.

air pressure Torque

Wrench

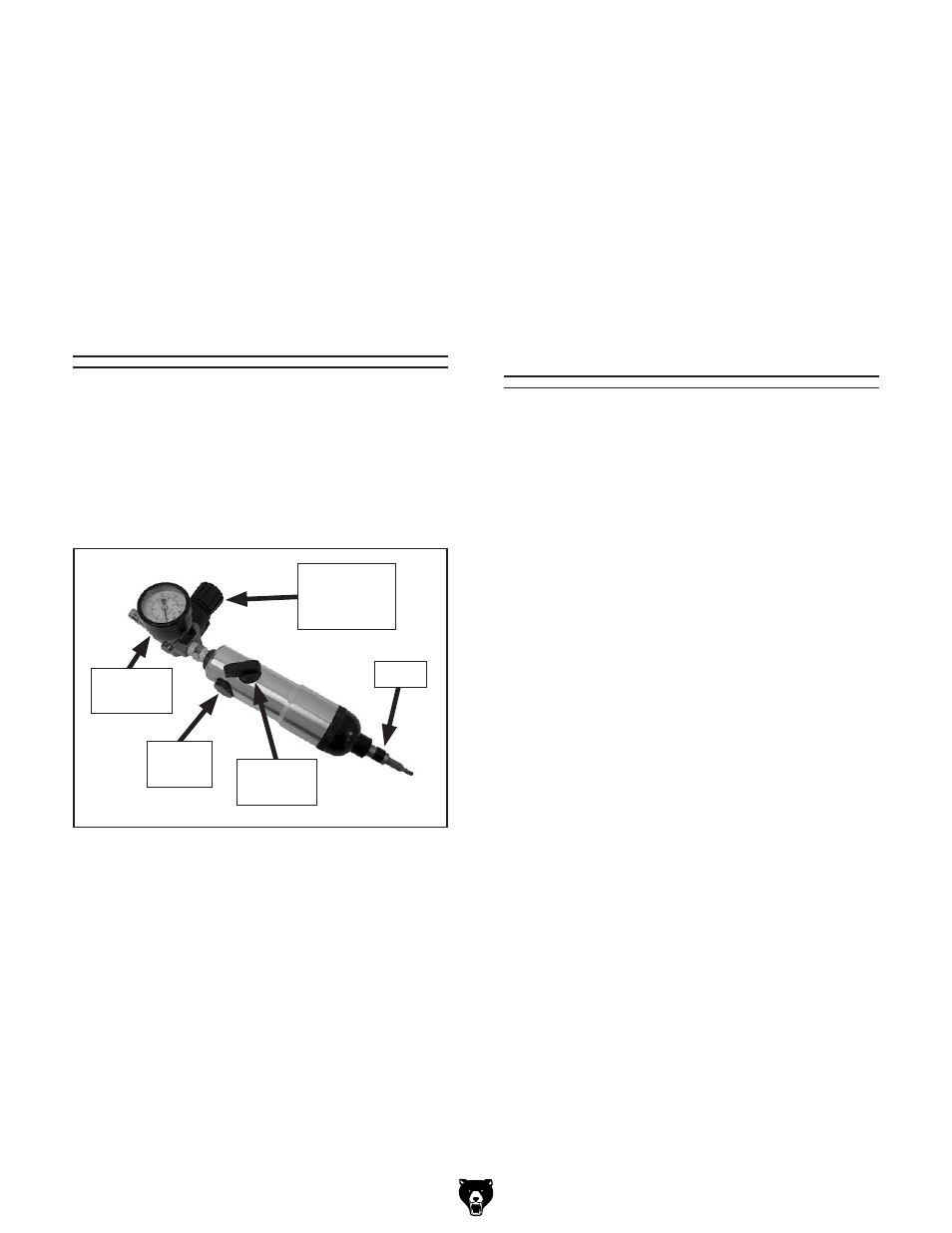

To fully tighten the Torx screws with the

included air pressure torque wrench:

1. insert a torx bit into the collet of the wrench.

2. Make sure the pressure gauge is fully thread-

ed onto the wrench, as shown in

Figure 59.

3. add two drops of pneumatic tool oil to the

incoming valve of the wrench to keep the

internal components lubricated.

4. Connect the wrench to a source of 90 psi

air pressure, then use the adjustment knob

of the pressure gauge to initially set the air

pressure to 20 psi on the gauge.

5. set the direction switch for clockwise rotation

and the setting dial to 2.

6. While carefully holding the insert in position,

insert the bit into the torx screw and press

the operation lever to seat the insert. repeat

this step with all remaining inserts.

7`. adjust the air pressure to 40 psi, then fully

tighten the torx screw to a final torque setting

of approximately 50–55 inch/pounds. repeat

with all remaining inserts.

Figure 59. Components of the air pressure

torque wrench.

pressure

gauge

pressure

adjustment

Knob

direction

switch

setting

dial

Collet