Site considerations, Mounting to shop floor notice, Floor load – Grizzly Extren Series Jointer g9860 User Manual

Page 17: Placement location, Bolting to concrete floors

Extreme series Jointer (Mfg. since 9/11)

-15-

Floor Load

refer to the

Model Specification comparison

chart on

page 5 for the weight and footprint speci-

fications of your machine. some residential floors

may require additional reinforcement to support

both the machine and operator.

placement Location

Consider existing and anticipated needs, size of

material to be processed through each machine,

and space for auxiliary stands, work tables or

other machinery when establishing a location for

your new machine. see

Figures 11–12 for the

minimum working clearances.

children and visitors may be

seriously injured if unsuper-

vised around this machine.

Lock entrances to the shop

or disable start switch or

power connection to prevent

unsupervised use.

Site considerations

Figure 11. Minimum working clearances.

A

B

although not required, we recommend that you

mount your new machine to the floor. Because

this is an optional step and floor materials may

vary, floor mounting hardware is not included.

generally, you can either bolt your machine to

the floor or mount it on machine mounts. Both

options are described below. Whichever option

you choose, it is necessary to level your machine

with a precision level.

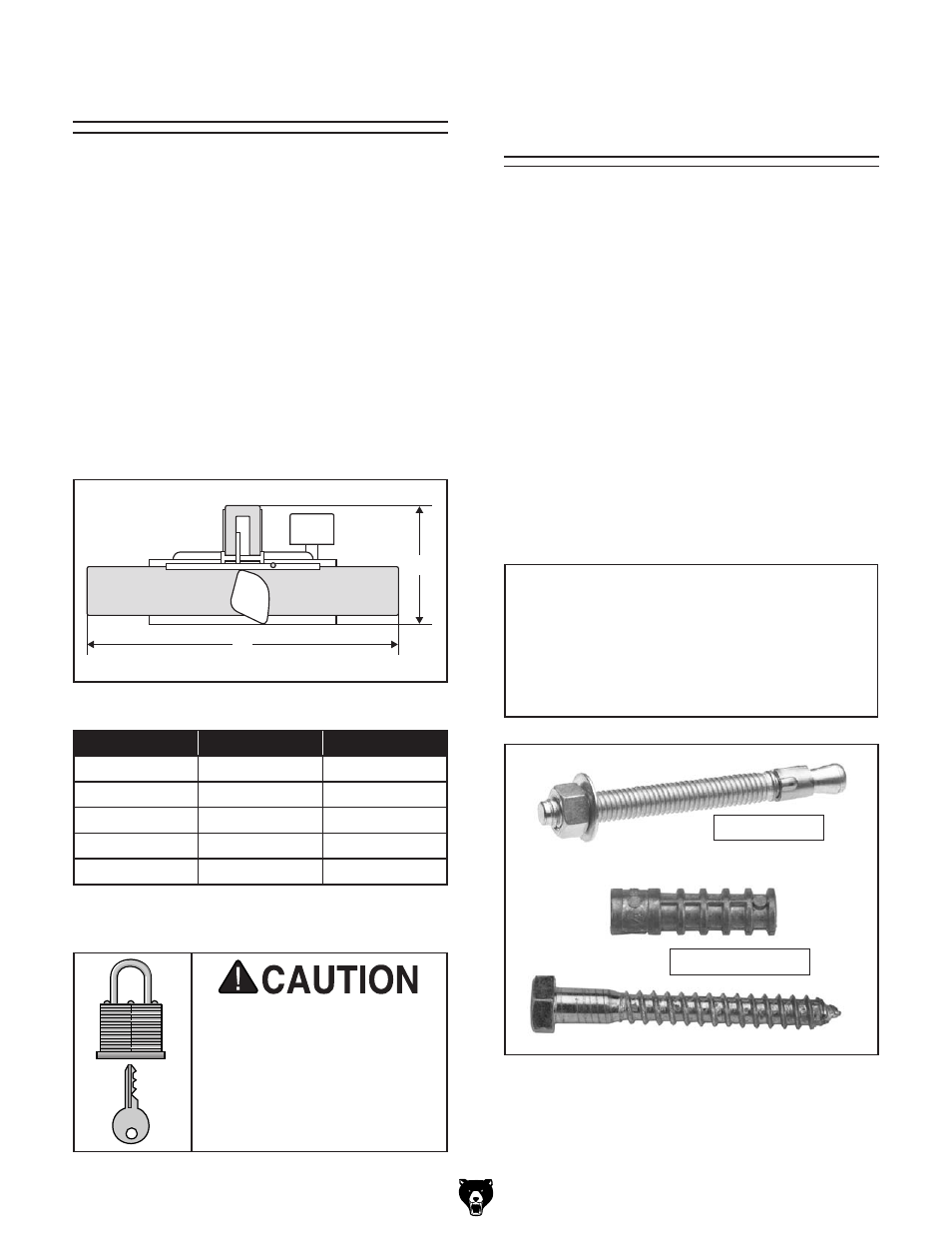

bolting to concrete Floors

anchor studs and lag shield anchors with lag bolts

(

Figure 13) are two popular methods for anchor-

ing an object to a concrete floor. We suggest

you research the many options and methods for

mounting your machine and choose the best that

fits your specific application.

Mounting to Shop

Floor

NOTICE

anchor studs are stronger and more per-

manent alternatives to lag shield anchors;

however, they will stick out of the floor,

which may cause a tripping hazard if you

decide to move your machine.

Figure 13. typical fasteners for mounting to

concrete floors.

anchor studs

lag shield & Bolt

Model

a

b

g9860

80"

35"

g9860zX

80"

35"

g9953

99

1

⁄

2

"

45

1

⁄

2

"

g9953zX

99

1

⁄

2

"

45

1

⁄

2

"

g9953zXF

99

1

⁄

2

"

45

1

⁄

2

"

Figure 12. Minimum working clearances by

model.