Piston repair – Graco Inc. 244592 User Manual

Page 42

Repair

42

309298J

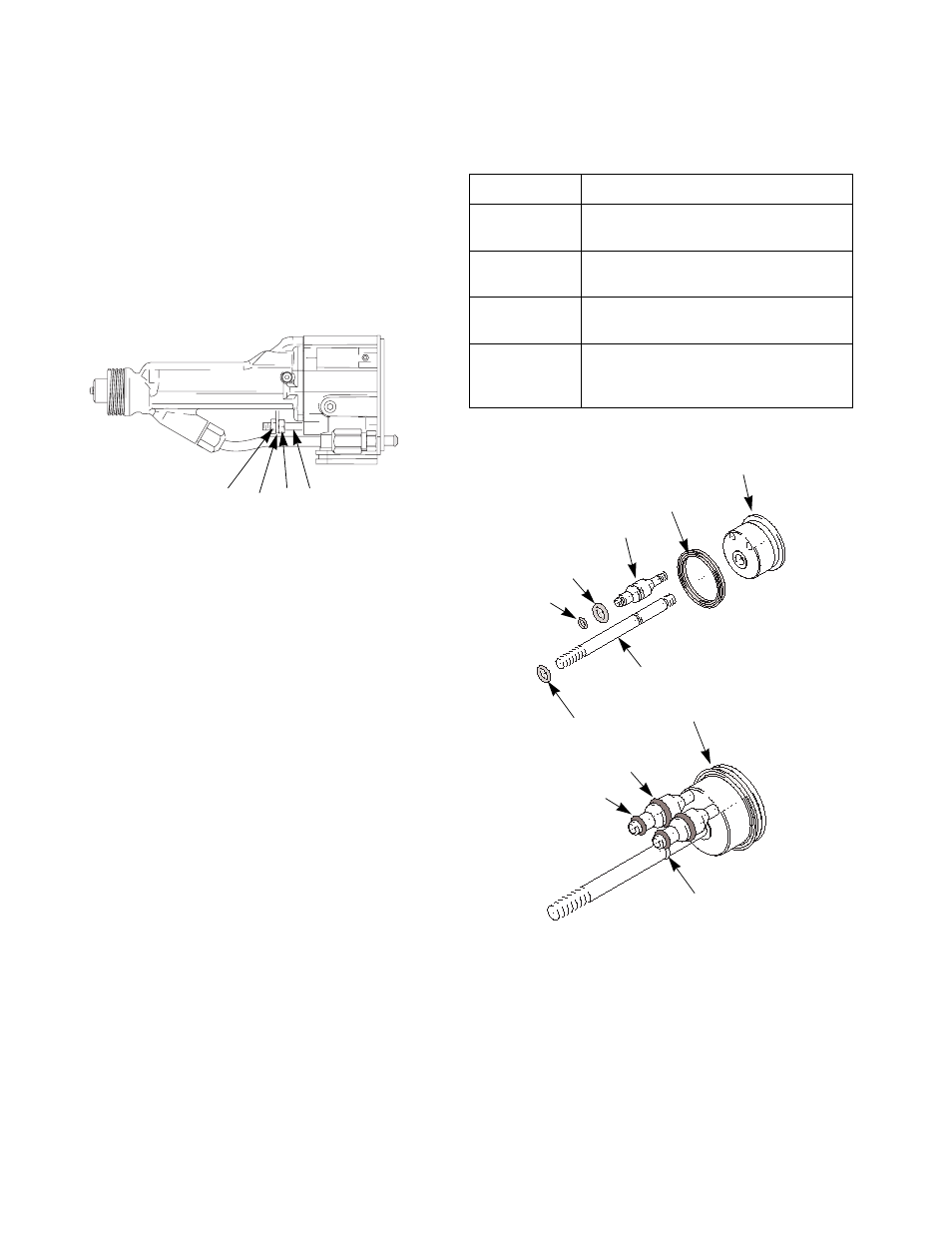

Piston Repair

1.

Prepare the gun for service, page 35.

2.

Remove the air cap, page 37. Remove the gun

shroud (2).

3.

Remove the jam nut (28), actuator arm (29), and

adjustment nut (30). See F

Fig. 30. Actuator Arm

4.

Push on the piston rod (34b) to push the piston out

the back of the gun.

5.

Inspect the o-rings (34e, 34f, 34g) and u-cup pack-

ing (34d) for damage. See Table 3 and F

6.

Lubricate the o-rings (34e, 34f, 34g) and u-cup

packing (34d) with non-silicone grease, Part No.

111265. Do not over-lubricate.

7.

Align the two stems (34c) with the holes in the gun

body and press the piston assembly into the back of

the gun until it bottoms.

8.

Install and adjust the actuator arm, page 43.

Fig. 31. Piston O-Rings

TI1732A

28

29 30 34b

Table 3: Piston O-Rings

Description

Function

Shaft O-Ring

(34g)

Seals cylinder air along the piston rod

(34b). Replace if air leaks along rod.

Front O-Ring

(34e)

Air shutoff seal. Replace if air leaks from

air cap when gun is de-triggered.

Back O-Ring

(34f)

Separates cylinder air from atomizing air.

U-Cup (34d)

Replace if air leaks from small vent hole

at back of manifold when gun is trig-

gered.

TI1575A

TI1576A

34a

34d

34c

34f

34e

34g

34b

34e

34g

34f

34d