Troubleshooting, Operations – Grizzly Slip Roll 16 Gauge G5771 User Manual

Page 26

-24-

g5771 50" slip roll 16 gauge

review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel-

ops. if you need replacement parts or you are unsure of your repair skills, then feel free to call our technical

support at (570) 546-9663.

SEctION 6: SERvIcE

troubleshooting

Operations

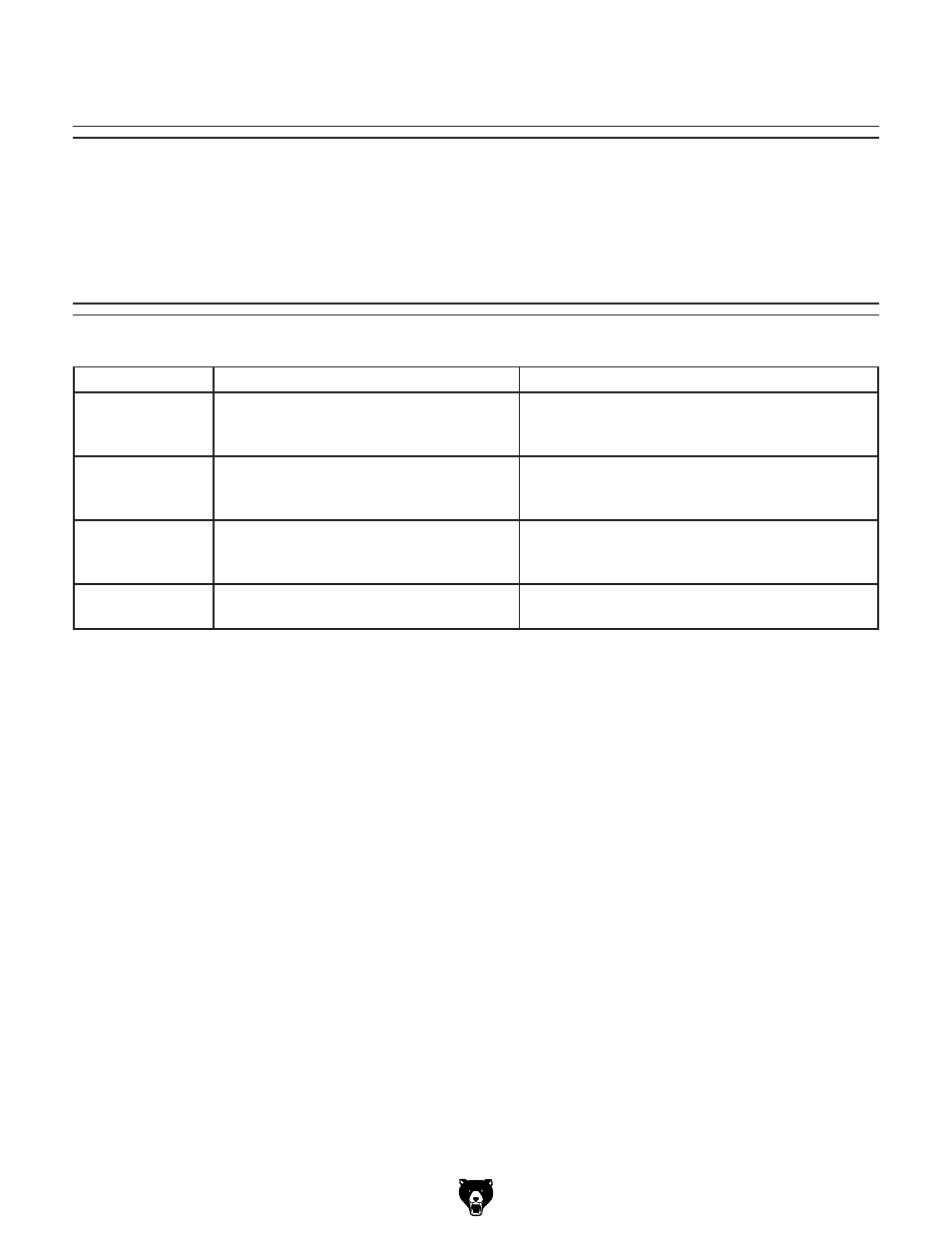

symptom

possible Cause

possible solution

slip roll creates

cones when trying

to create cylinders.

1. rollers are not parallel.

1. adjust rear roller adjustment knobs as necessary to

be sure the rear roller and upper roller are parallel.

a noticeable crease

is formed in the

workpiece.

1. excessive pressure applied in one spot.

1. reduce the radius and perform the bend in several

passes.

Crank does not turn

upper and lower

rollers.

1. gearbox end of upper roller is not secure.

2. gears are damaged.

1. re-center the bushing and secure the hex bolt and

jam nut (

Step 5 on Page 20).

2. Check/replace gears.

slip roll does not

bend material.

1. Machine capacities exceeded.

2. rear roller not engaged.

1. use materials within the capacity of the slip roll.

2. Check/adjust rear roller.