Flat rolling, Preparation – Grizzly Slip Roll 16 Gauge G5771 User Manual

Page 16

-14-

g5771 50" slip roll 16 gauge

flat Rolling

the Model g5771 can be used to flat roll sheet

metal up to 16 gauge. this can be done to

straighten, flatten, and slightly reduce the thick-

ness of workpieces.

Preparation

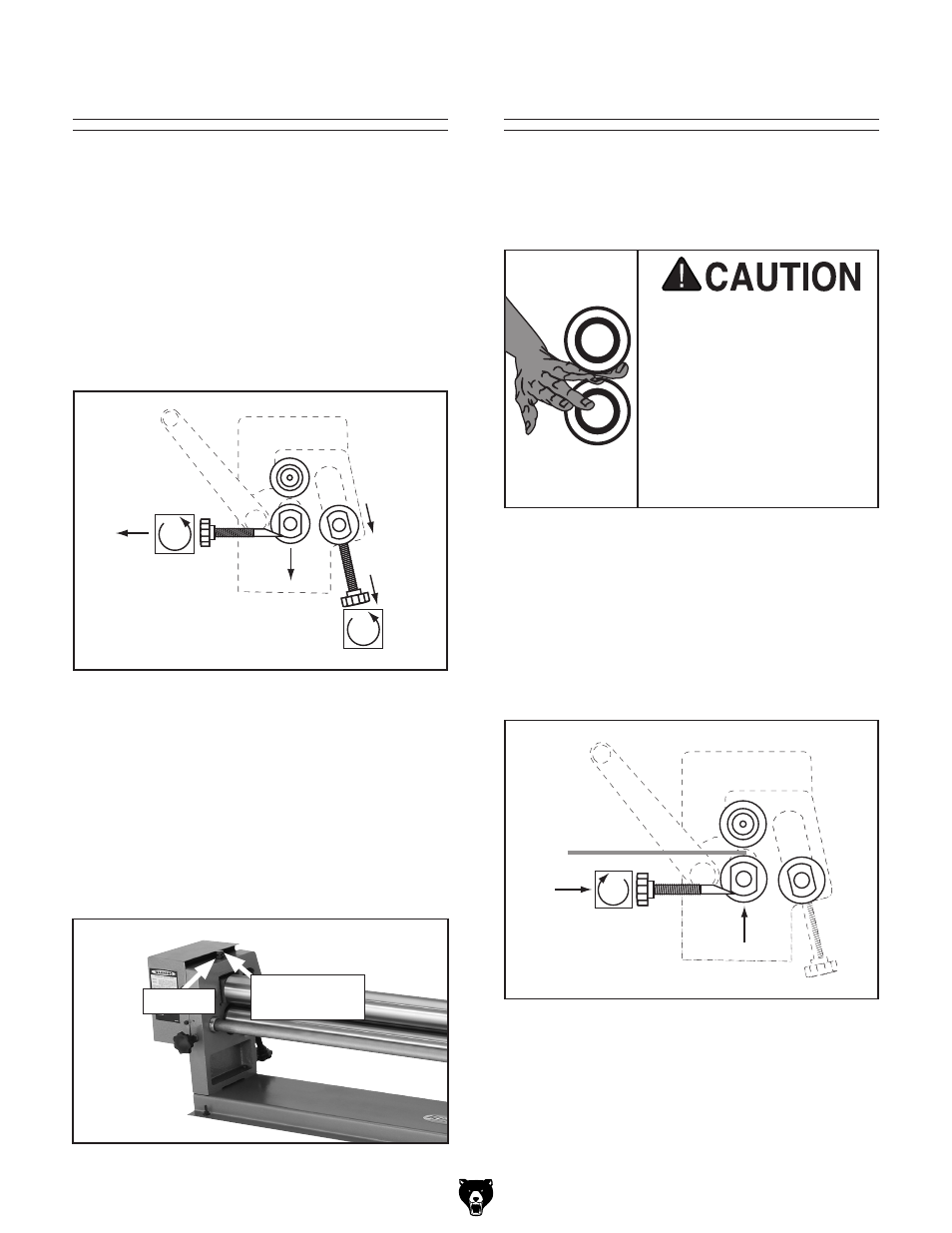

Before every use, follow these procedures to set

up your slip roll for safe, accurate, and efficient

use.

to prepare the slip roll for use:

1. turn the thickness adjust knob to lower the

lower roller to approximately

1

/

4

" below the

upper roller. use calipers or a spacer to set

the distance between the rollers evenly at

each end (

figure 12).

88L

88L

figure 12. slip roll preparation.

2. lower the rear roller until it is approximately

even with the lower roller. use calipers or a

spacer to set the distance between the rear

roller and upper roller evenly at each end.

3. Make sure the upper roller bushing bolt is

threaded into the upper roller bushing and

the jam nut is tightened against the cast-iron

base (

figure 13).

figure 13.

Upper roller bushing.

8L

figure 14. raising lower roller for flat rolling.

to flat roll a workpiece:

1. place the workpiece between the upper and

lower rollers, as shown in

figure 14. turn the

thickness adjust knobs to lift the lower roller

until the workpiece is held snug between the

upper and lower rollers. Be sure to turn the

thickness adjust knobs equal amounts.

upper roller

Bushing Bolt

Jam nut

the main rollers of this

machine present a pinch-

ing hazard. Make sure no

body part or clothing is

near the area between the

rollers. failure to follow this

warning may result in fin-

gers, hair, or clothing being

pulled into the machine,

causing personal injury.