17 routine cleaning and inspection – Glow-worm Xtramax User Manual

Page 29

29

4000116705-2

17 Routine Cleaning and Inspection

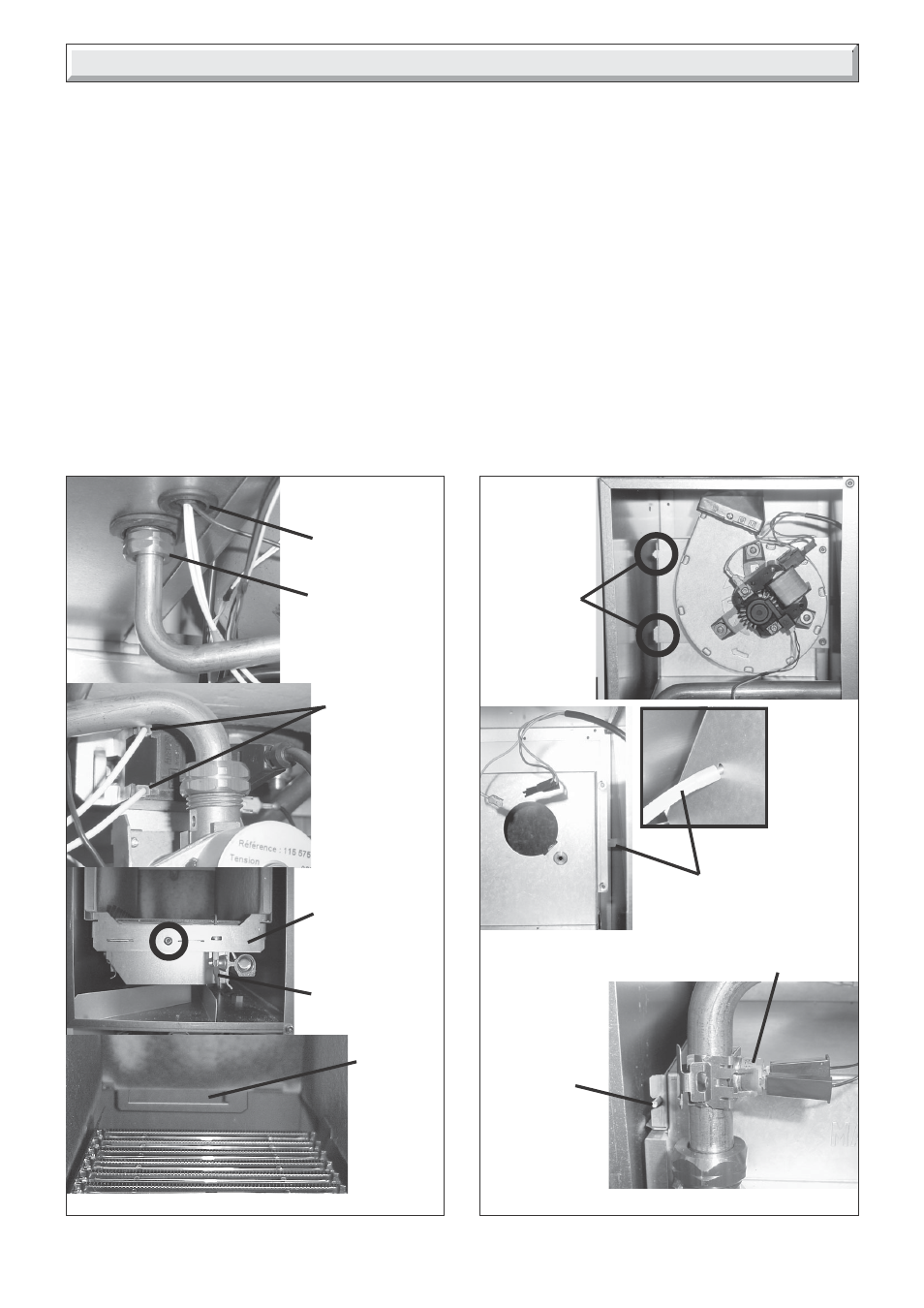

17.8 Burner, refer to diagram 17.3.

• Undo main gas supply nut from under the sealed chamber.

Note: The washer between main burner and main burner gas

supply must be kept for use on reassembly.

• Pull off ignition leads from ignition unit.

• Pull off flame sense lead from flame sense electrode.

• Unscrew and remove burner support bracket securing screw

and remove bracket.

• Remove burner from boiler by lifting up and pulling forwards

easing the leads through the grommet, taking care not to

damage insulation.

• Clean burner by washing in soapy water. Dry thoroughly

before refitting.

• When refitting burner ensure that rear of burner locates into

location slot and the injector locates correctly through the

grommet.

Note: To gain access to injectors for removal, refer to Section,

20.24 in Replacement of Parts.

9341

Diagram 17.3

11755

9345

MAIN GAS

SUPPLY NUT

GROMMET

BURNER

SUPPORT

BRACKET

BURNER

LOCATION

SLOT

FLAME

SENSE

LEAD

IGNITION

LEADS

11756

17.9 Heat exchanger, refer to diagram 17.4.

• Disconnect electrical connections from fan.

• Unscrew and remove two fan retaining screws from the right

hand side edge of fan mounting plate.

• Remove fan with mounting plate attached by pulling forward

and out of boiler.

• Remove air pressure switch sensing tube at rear of flue hood.

• From front of boiler carefully unclip wire spring retainers from

side of flue hood.

• Remove the overheat thermostat by unclipping from the

heating return pipe.

• Lift flue hood clear of heat exchanger and examine for debris.

• Using a soft brush or vacuum clean as required.

DO NOT USE ANY TOOL LIKELY TO DAMAGE PAINTED

FINISH OF HEAT EXCHANGER.

Note: When re-fitting fan, make sure that the two lugs on the fan

mounting plate engage in the flue hood

11757

Diagram 17.4

11760

11759

AIR PRESSURE SWITCH

SENSING TUBE

WIRE SPRING

RETAINER

2 OFF

FAN

RETAINING

SLOTS

OVERHEAT

THERMOSTAT

➜

11758