6 boiler location, flue and ventilation – Glow-worm Xtramax User Manual

Page 14

14

4000116705-2

6 Boiler Location, Flue and Ventilation

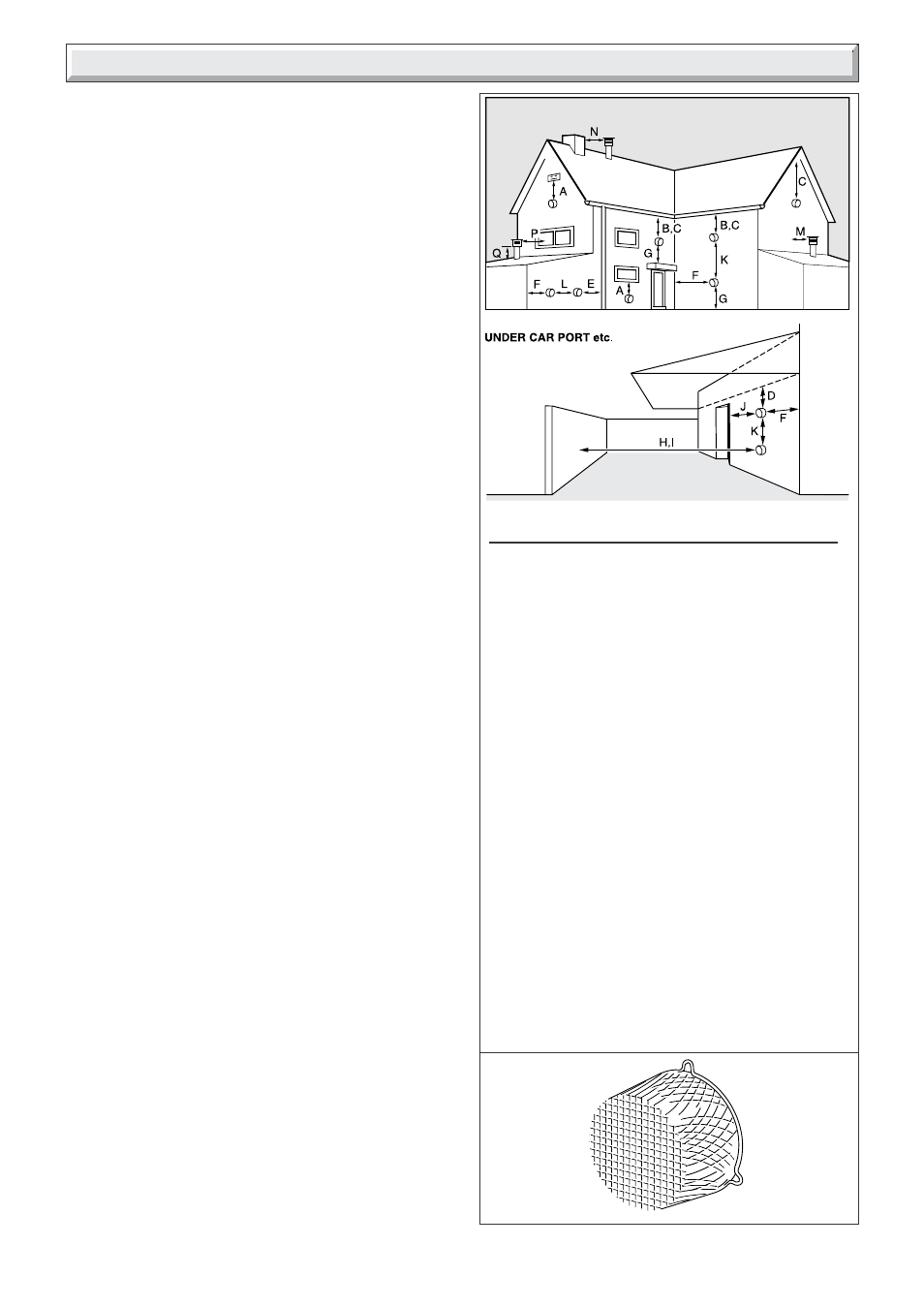

Diagram 6.2

MINIMUM SITING DIMENSIONS FOR THE

POSITIONING OF FLUE TERMINALS

MM

HORIZONTAL FLUES

A DIRECTLY BELOW, ABOVE OR

HORIZONTALLY TO AN OPENING, AIR BRICK,

OPENING WINDOWS, AIR VENT, OR ANY

OTHER VENTILATION OPENING

300

B BELOW GUTTER, DRAIN/SOIL PIPE

75

C BELOW EAVES

200

D BELOW A BALCONY OR CAR PORT

200

E FROM VERTICAL DRAIN PIPES AND

SOIL PIPES

150

F

FROM INTERNAL/EXTERNAL CORNERS

OR TO A BOUNDARY ALONGSIDE THE

TERMINAL

300

G ABOVE ADJACENT GROUND OR

BALCONY LEVEL

300

H FROM SURFACE OR A BOUNDARY

FACING THE TERMINAL

600

I

FACING TERMINALS

1200

J

FROM OPENING (DOOR/WINDOW)

IN CAR PORT INTO DWELLING

1200

K VERTICAL FROM A TERMINAL

1500

L

HORIZONTALLY FROM A TERMINAL

300

VERTICAL FLUES

M FROM ADJACENT WALL TO FLUE

300

N FROM ANOTHER TERMINAL

600

P FROM ADJACENT OPENING OR WINDOW

1000

Q ABOVE ROOF LEVEL

300

Diagram 6.3

11508

6.4 Terminal position

The minimum acceptable spacings from the terminal to

obstructions and ventilation openings are shown in diagram

6.2.

The boiler must be installed so that the terminal is exposed to

the external air.

Warning:

Do not obstruct the outside terminal of the boiler.

6.5 Terminal guard, see diagram 6.3

A terminal guard is required if persons could come into contact

with the terminal or the terminal could be subject to damage.

If a terminal guard is required, it must be positioned to provide

a minimum of 50mm clearance from any part of the terminal and

to be central over the terminal.

A suitable terminal guard type K3 can be supplied by:

Tower flue components Ltd.

Morley Road

Tonbridge

Kent

TN9 1RA

6.6 Flue options

There are various flue systems to choose from as follows:

Horizontal telescopic top flue pack.

Horizontal top flue pack.

Horizontal extended flue pack.

Vertical flue pack.

Twin flue pack.

Extensions, 90° and 45° bends.

For detailed information refer to flue options guide. This is

available from your nearest stockist.