2 general information, 3 heating system design – Glow-worm Xtramax User Manual

Page 10

10

4000116705-2

2 General Information

IMPORTANT NOTICE.

Where no British Standards exists, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.

Refer to Manual Handling Operations, 1992 regulations.

The installation of this boiler must be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

1.1 Sheet Metal Parts

WARNING: When installing the appliance, care should be

taken to avoid any possibility of personal injury when handling

sheet metal parts.

1.2 Statutory Requirements

The installation of the boiler MUST be carried out by a competent

person in accordance with the relevant requirements of the

current issue of:

Manufacturer’s instructions, supplied.

The Gas Safety (Installation and Use) Regulations, The Building

Regulations, The Building Standards (Scotland) Regulations

(applicable in Scotland), local Water Company Bylaws, The

Health and Safety at Work Act, Control of Substances Hazardous

to Health, The Electricity at Work Regulations and any applicable

local regulations.

Detailed recommendations are contained in the current issue of

the following British Standards and Codes of Practice, BS4814,

BS5440 Part 1 and 2, BS5449, BS5546, BS6700, BS6798,

BS6891 and BS7074 Part 1 and 2, BS7478, BS7593, BS7671.

Manufacturer’s notes must not be taken as overriding statutory

obligations.

BSI Certification

This boiler certificated to the current issue of EN 483 for

performance and safety.

It is important that no alteration is made to the boiler, without

permission, in writing, from H

epworth Heating Ltd.

Any alteration that is not approved by

Hepworth Heating Ltd.,

could invalidate the warranty and could also infringe the current

issue of the Statutory Requirements.

1.3 Gas Supply

The gas installation must be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge

in accordance with the above standard.

• The XTRAMAX is for use ONLY with sealed central heating

systems.

• Heating surfaces may consist of radiators, convectors or fan

assisted convectors.

• The appliance

can be piped directly to an underfloor heating

system without the need for a mixing bottle. The maximum

central heating flow temperature can be set to 53°C on the boiler

printed circuit board during commissioning.

0

10

20

30

40

50

60

1200

1000

800

600

400

200

0

1

2

3

4

5

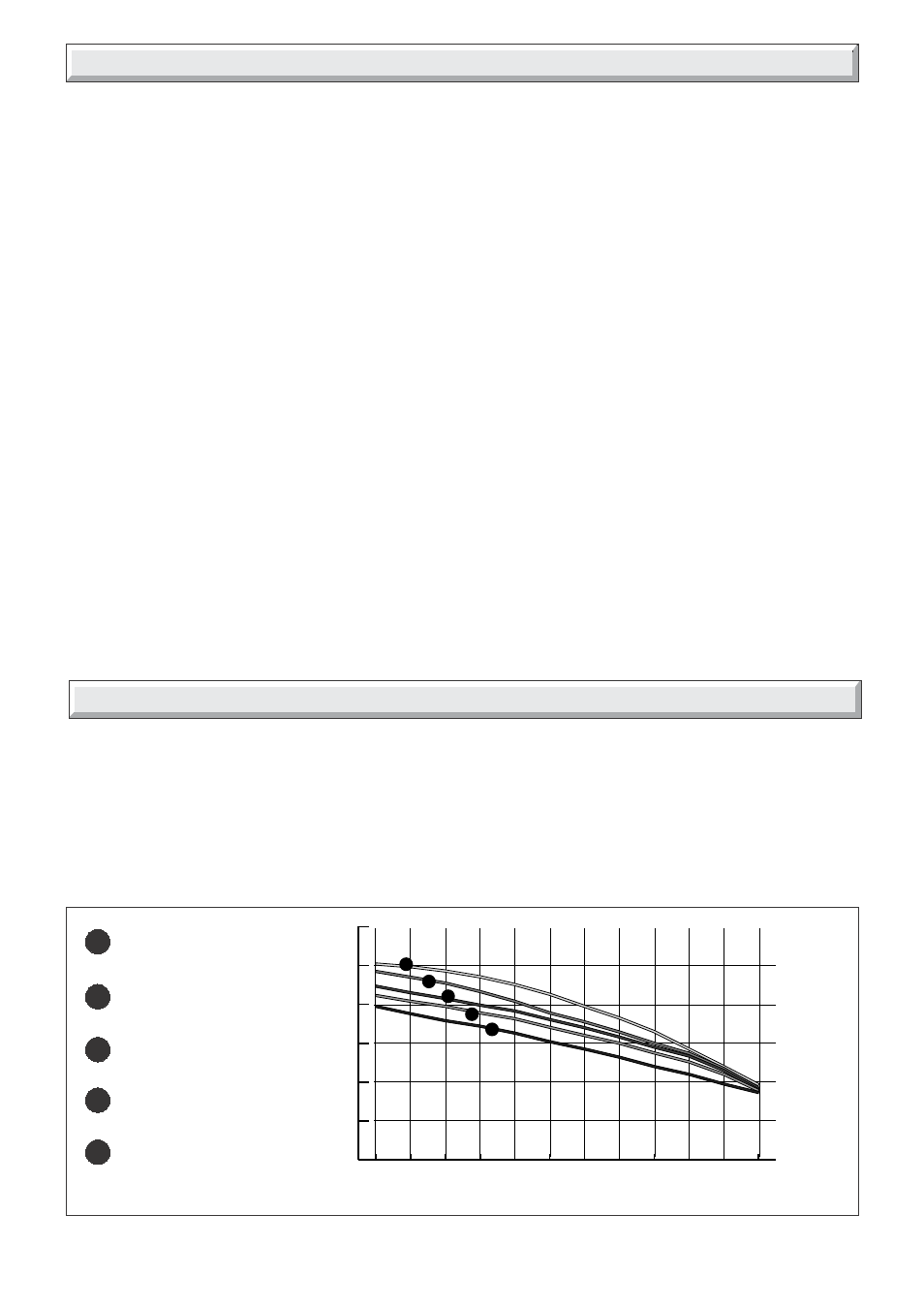

Pom 010 a

Flow rate through heating system (I/h)

(10 kPa = 1 m WG)

1

2

3

4

5

Bypass fully shut

Open 1/4 turn

Open 1/2 turn

Open 1 turn

Open 2 turns

Available pressure (kPa) between

heating supply and return lines

Diagram 3.1

3 Heating System Design

• Pipe sectional areas shall be determined in accordance with

normal practices, using the output/pressure curve

(diagram 3.1). The distribution system shall be calculated in

accordance with the output requirements of the actual system,

not the maximum output of the boiler. However, provision shall

be made to ensure sufficient flow so that the temperature

difference between the flow and return pipes be less than or

equal to 20°C. The minimum flow is 400 l/h.