7 safety discharge 8 fixing jig – Glow-worm Xtramax User Manual

Page 15

15

4000116705-2

9129

Discharge from

HTG prv on jig

Discharge from

DHW safety

valves

Gully

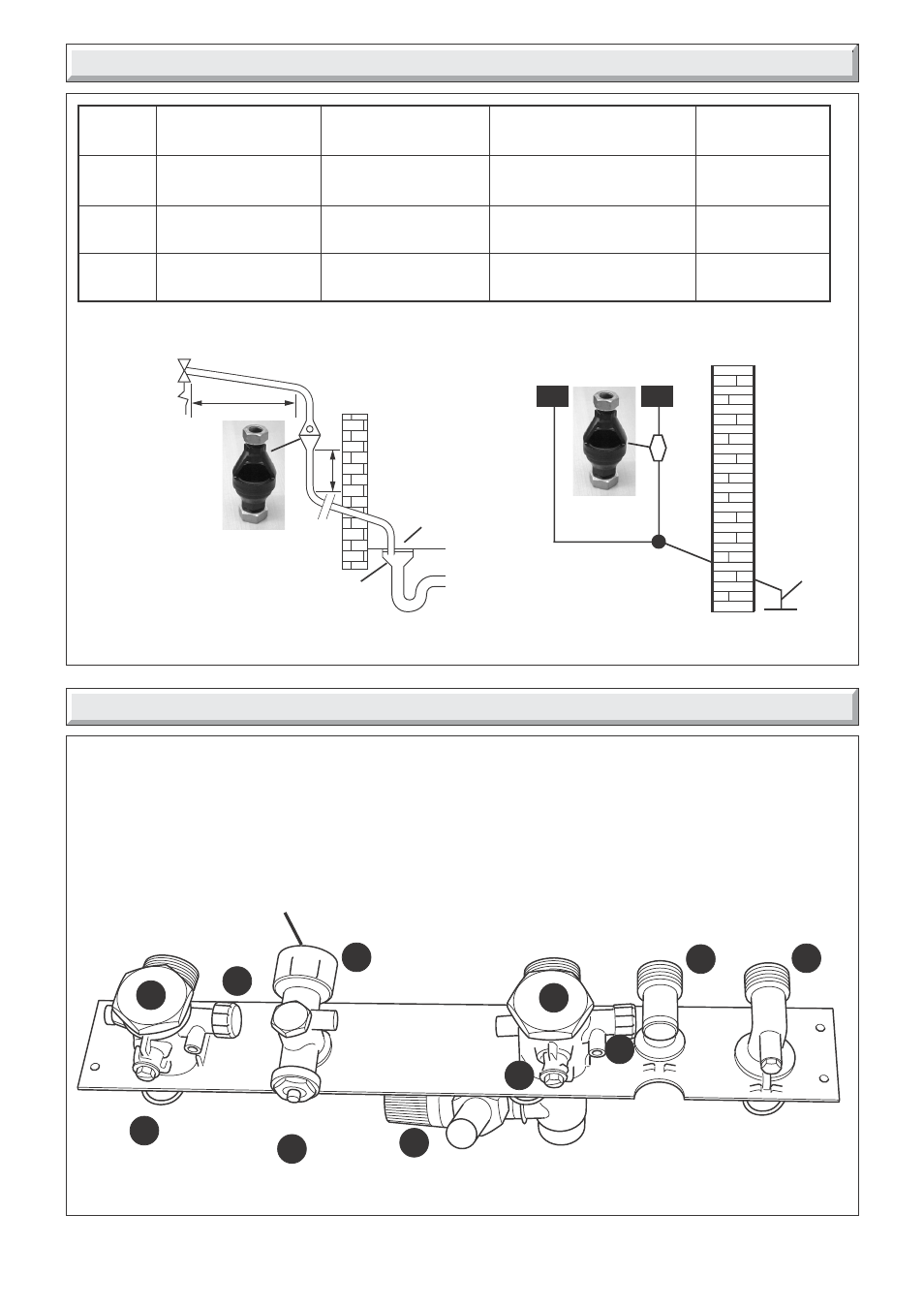

Diagram 7.1

Valve outlet

size

Maximum resistance allowed

expressed as a length of straight

pipe i.e. no elbows or bends

Resistance created

by each elbow

or bend

Minimum size of discharge

pipe D2 from tundish

Minimum size of

discharge to tundish

D1

G 1/2

15 mm

22mm

up to 9 m

0.8 m

28 mm

up to 18 m

1.0 m

35 mm

up to 27 m

1.4 m

G 3/4

22 mm

28 mm

up to 9 m

1.0 m

35 mm

up to 18 m

1.4 m

42 mm

up to 27 m

1.7 m

G 1

28 mm

35 mm

up to 9 m

1.4 m

42 mm

up to 18 m

1.7 m

54 mm

up to 27 m

2.3 m

Discharge pipe (D2) from

turndish with continuous fall see table

above for size examples.

Discharge pipe (D1) from

temperature relief valve to turndish

Tundish

(Supplied)

Fixed grating

Trapped

gully

Safety

device eg.

temperature

relief valve

500mm

max.

300mm min.

9131

7 Safety Discharge

8 Fixing Jig

D1

D2

The fixing jig is made up, from left to right, as follows:

A - Heating return fitting with isolating valve (v) and drain knob (u).

B - Cold water inlet fitting with isolating valve (m) and factory fitted flow restrictor and filter (not shown).

C - Heating flow fitting with isolating valve (q) drain knob (r) and safety valve (10).

D - Domestic hot water outlet.

E - Gas service cock.

Diagram 8.1

9126

Tundish

(Supplied)

➜

u

➜

m

v

q

r

10

A

B

C

D

E

9317

9317

(Fitted inside) Flow

restrictor and cold water

inlet filter