Disassemble pinion bearing cage – Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 98

Section 2

Removal and Disassembly

10

Disassemble Pinion Bearing

Cage

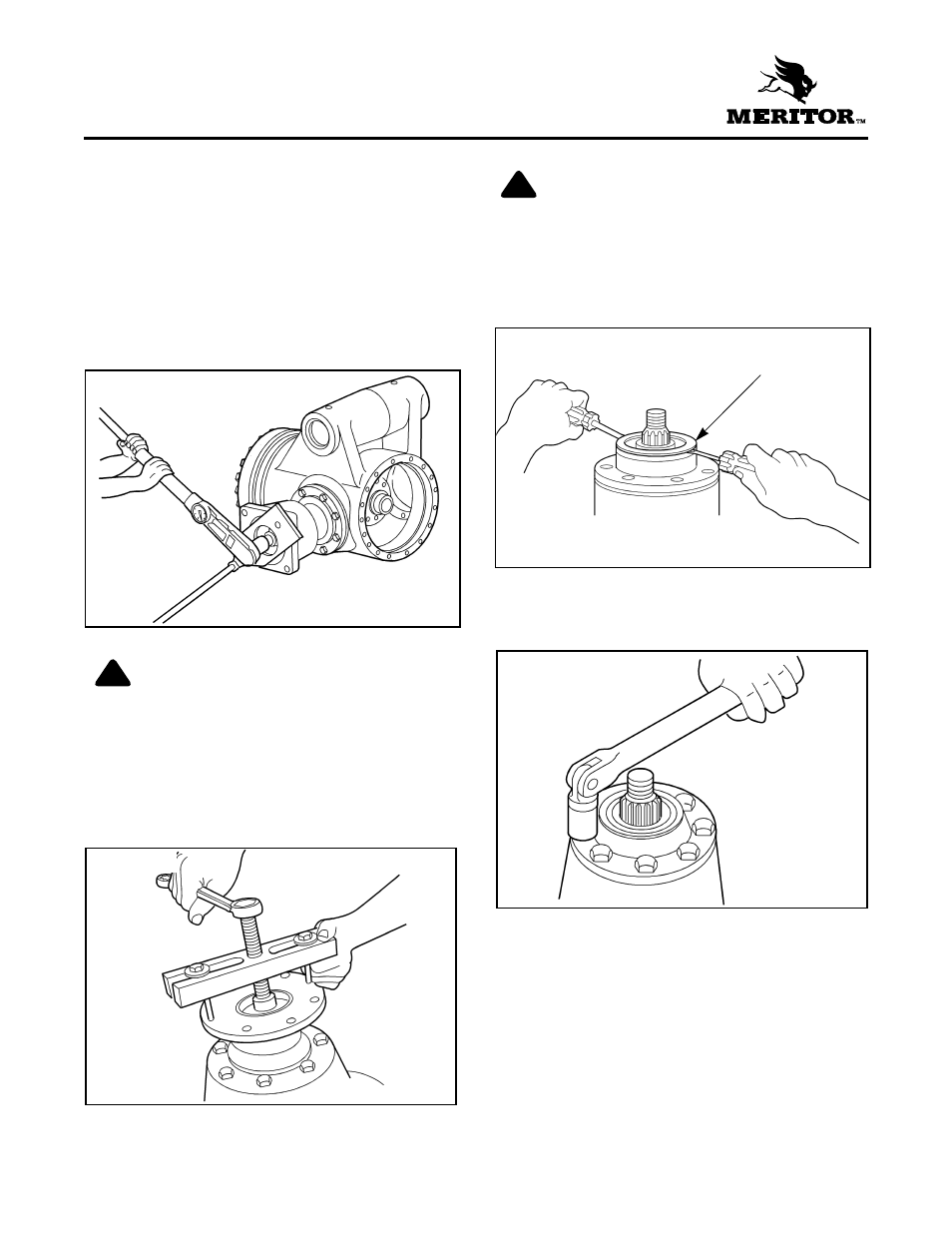

1. If pinion bearing cage was not removed, hold

yoke, flange or splined sleeve with appropriate

holder to remove pinion nut. Figure 2.32

If pinion bearing cage was already removed,

place it on main housing and fasten with two

capscrews.

CAUTION

Do not use a hammer or mallet to loosen or

remove yoke, flange or splined sleeve. The

hammer or mallet can damage the parts or cause

alignment problems. Do not damage the oil seal

surface area.

2. Remove yoke, flange or splined sleeve from drive

pinion with appropriate puller tool. Figure 2.33.

!

CAUTION

To avoid oil leaks, be careful not to damage the

mounting surface of the bearing cage.

3. Remove pinion oil seal. Pry at several points

around circumference between seal, flange and

bearing cage. Figure 2.34.

4. Remove capscrews and washers that fasten pinion

bearing cage on main housing. Figure 2.35.

!

Figure 2.32

Figure 2.34

Figure 2.35

Figure 2.33

OIL SEAL