Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 119

31

Section 4

Assembly and Installation

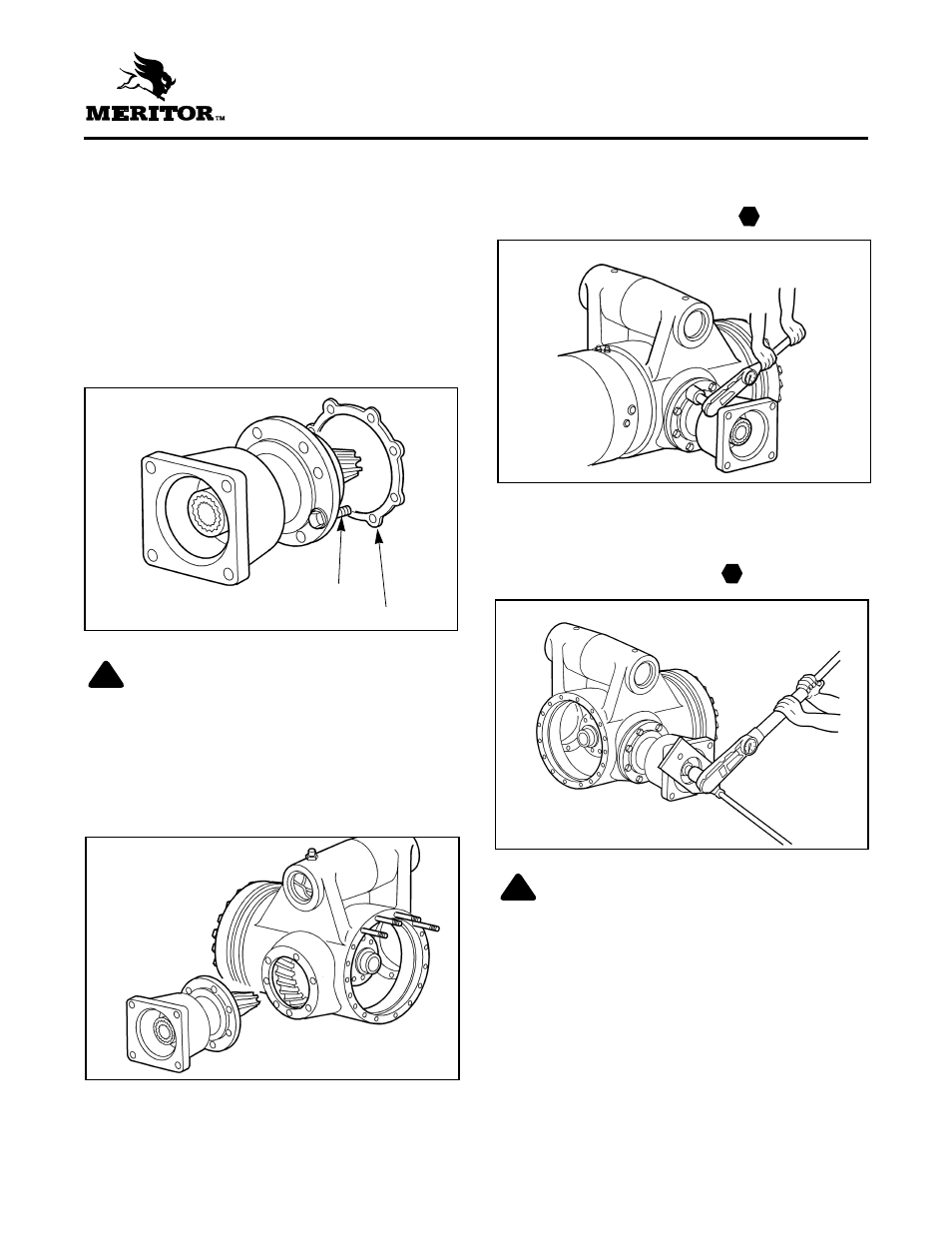

Install Pinion Bearing Cage

Assembly on Main Housing

NOTE

Use minimum of three shims in pack. If pack is

made from different thickness shims, install

thinnest shims on both sides of pack for

maximum sealing.

1. Install correct shim pack between bearing cage

and main housing. Figure 4.24.

WARNING

Do not hit steel parts with a steel hammer during

assembly and installation procedures. Parts can

break and cause serious personal injury.

2. Install drive pinion and bearing cage into carrier. If

necessary, use rubber, plastic or leather mallet to

tap assembly into position. Figure 4.25.

!

3. Install two capscrews and washers that fasten

bearing cage. Tighten to minimum torque of

67 lb-ft (90 N•m). Figure 4.26.

4. Install yoke or flange and pinion nut. Fasten yoke

or flange with appropriate tool. Tighten pinion nut

to minimum specified torque of 465-570 lb-ft

(630-775 N•m). Figure 4.27.

CAUTION

The fit between input yoke or flange splines and

drive pinion is tight. To install yoke or flange into

pinion, use pinion nut and appropriate tool to

fasten it. Never use hammer or mallet. A hammer

or mallet will damage yoke or flange.

!

Figure 4.25

Figure 4.27

Figure 4.26

Figure 4.24

CAPSCREW

SHIM PACK

T

T