Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 109

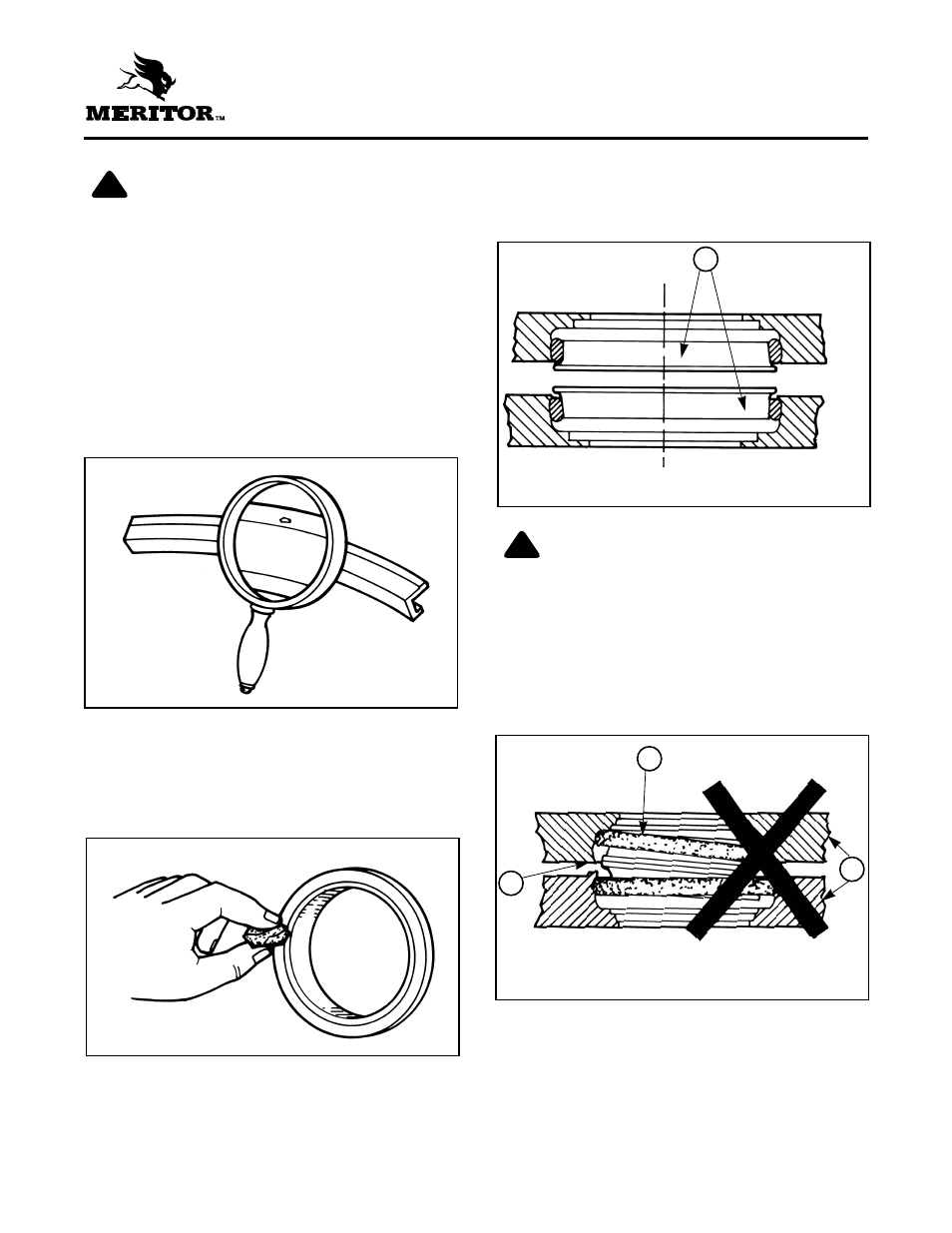

10. Make sure both bores are correctly aligned and

concentric. Move slowly and carefully.

Figure 3.19.

CAUTION

Do not force rings abruptly against each other. A

strong impact may break the oil seal

components. When seal is installed properly,

fasten all components well.

If DUO-CONE oil seal is installed incorrectly, these

conditions can result:

•

Toric ring can warp. Figure 3.20.

!

CAUTION

•

Misalignment or a twisted Toric ring may cause

leakage in the DUO-CONE oil seal. If installation

was not correct, remove oil seal from bore and

repeat steps 3-6.

•

A Toric ring must never slide on any ramp of oil

seal ring or bore. To prevent sliding, wait at

least two minutes for trichloroethylene to

evaporate before continuing with installation.

When in the correct position, Toric ring must

roll only on ramps.

•

A small piece of lint can separate the oil seal

surfaces and cause leaks. Figure 3.17.

8. Clean oil seal surfaces with lint-free cloth or paper.

9. Apply a thin, uniform film of clean oil on oil seal

surfaces with cloth or clean finger. Do not get oil

on Toric ring. Figure 3.18.

!

21

Section 3

Prepare Parts for Assembly

Figure 3.17

Figure 3.19

Figure 3.20

Figure 3.18

1

1

2

5