Liquid adhesive, Disassemble locked sets, Cleaning – Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 105: Reassembly, Application

17

Section 3

Prepare Parts for Assembly

Liquid Adhesive

Meritor uses the following liquid adhesives to retain

threaded fasteners:

Product

Type

Color

Cure Time

Loctite

271 High

Red

2 hours

241 Medium

Blue

6 hours

221 Low

Violet

6 hours

Three Bond

1305 High

Red

5 hours

1334 Medium

Green

5 hours

1341 Low

Blue

10 hours

Disassemble Locked Sets

CAUTION

Do not use impact wrenches or strike components

with a hammer.

To disassemble sets originally locked with liquid

adhesive, use the regular mechanical disassembly

procedure.

If the removal of a capscrew, for example, becomes

difficult due to a worn head or unusually high

breakaway torque, the locking strength can be

reduced by heating the threaded area to

approximately 300°F (150°C). Heat slowly to avoid

thermal stresses on the differential case and gears.

Cleaning

WARNING

To avoid serious personal injury, trichloroethylene

must not come in contact with your skin. Do not

smoke and avoid breathing vapors in closed

rooms without ventilation. Do not use

trichloroethylene near flames, welding operations

or hot surfaces exceeding 900°F (482°C).

Clean capscrew, nut or bolt tapped hole and fastener

thread carefully. Use a cleaning solvent such as

trichloroethylene or equivalent to remove dirt, oil,

grease or moisture.

!

!

Reassembly

•

Check the type of liquid adhesive to be used and

where the adhesive is to be applied.

•

In threaded holes where fasteners did not require

removal, check each one for tightness by applying

the minimum amount of specified torque.

•

If fasteners do not rotate, they are tightened

properly.

•

If fasteners rotate to any degree, they must be

removed and liquid adhesive must be applied.

Application

1. Apply liquid adhesive to:

•

Bolt threads when component has open hole.

Before installing bolts, visually check to make

sure that liquid adhesive has filled gap

between threads.

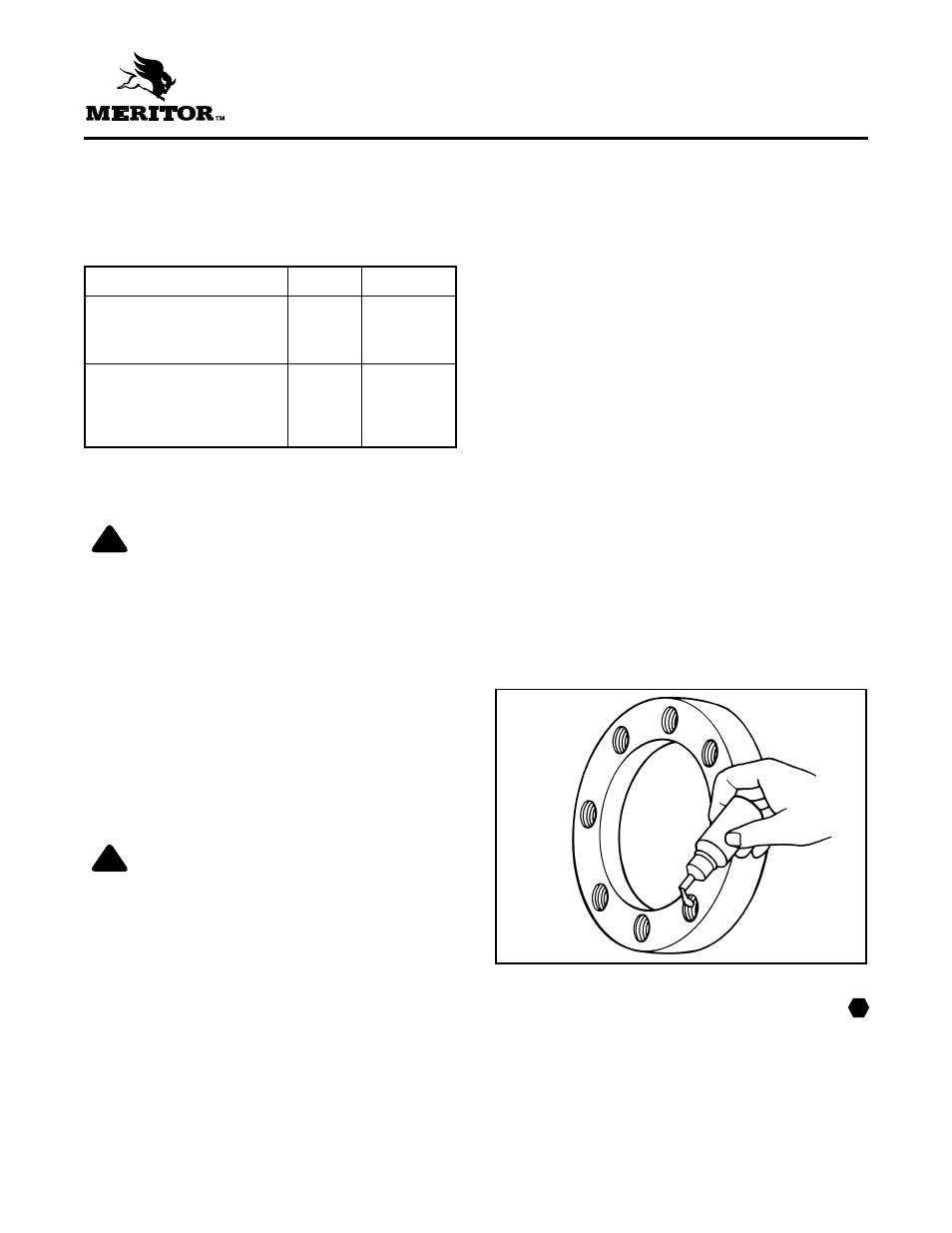

•

Threaded hole when component has blind

hole. Allow 4 to 6 drops to run down side of

each hole. If liquid adhesive is applied to bolt,

trapped air in hole will create back pressure

and “blow out” liquid adhesive as bolt

advances. Figure 3.7.

2. Tighten fasteners with recommended torque.

Figure 3.7

T