Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 117

29

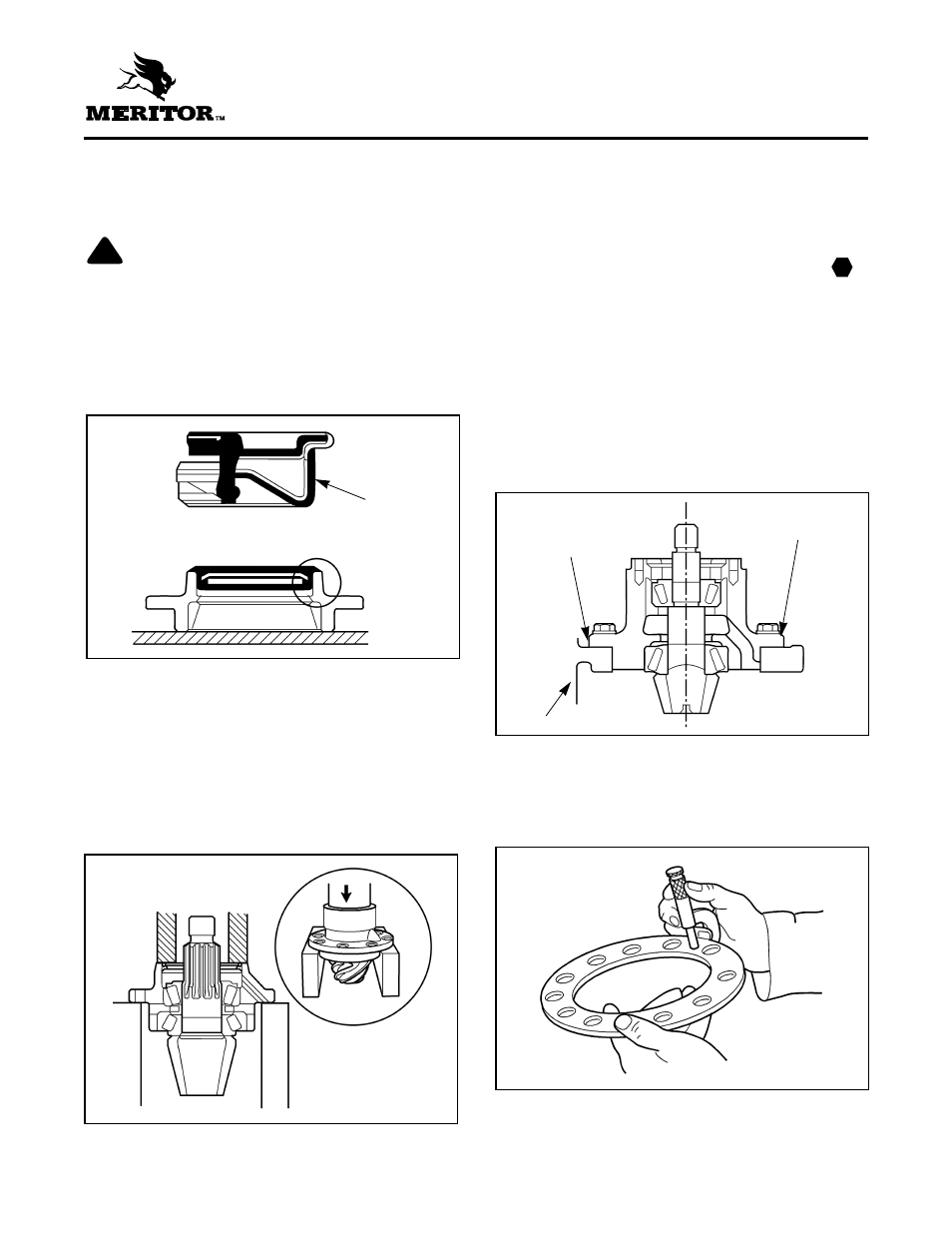

10. After getting specified preload, remove bearing

cage from main housing and disassemble yoke or

input flange.

CAUTION

Make sure oil seal lips are clean and free from

dirt. Dirt can cause leakage between seal and

yoke or flange.

11. Install pinion oil seal with the appropriate tool:

a. Apply extreme pressure lithium soap grease to

oil seal lips. Figure 4.19.

b. Apply 3M Industrial Adhesive or equivalent to

oil seal outer surfaces. Figure 4.19.

c. Press oil seal into bearing until seal flange is

flat against top of bearing cage. Use the

correct size sleeve or seal driver that fits

against metal flange of seal. The diameter of

the sleeve must be larger than diameter of

flange. Figure 4.20.

!

d. Install yoke or flange and pinion nut

into pinion.

e. Tighten pinion nut to specified torque after

installing pinion bearing cage into main

housing of 465-570 lb-ft (630-775 N•m).

Adjust Thickness of Pinion

Bearing Cage Shim Pack

(Depth of Pinion)

NOTE

Use this procedure if a new drive pinion and ring

gear set is installed or if the depth of the drive

pinion has to be adjusted. Figure 4.21.

1. Use a micrometer to measure the thickness of the

old shim pack that was removed from under the

pinion cage. Record the measurement for later

use. Figure 4.22.

Figure 4.19

Figure 4.21

Figure 4.22

Figure 4.20

SHIM PACK

BEARING CAGE

MAIN

HOUSING

INDUSTRIAL

ADHESIVE

Section 4

Assembly and Installation

T