Assemble trumpet assembly – Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 123

35

Section 4

Assembly and Installation

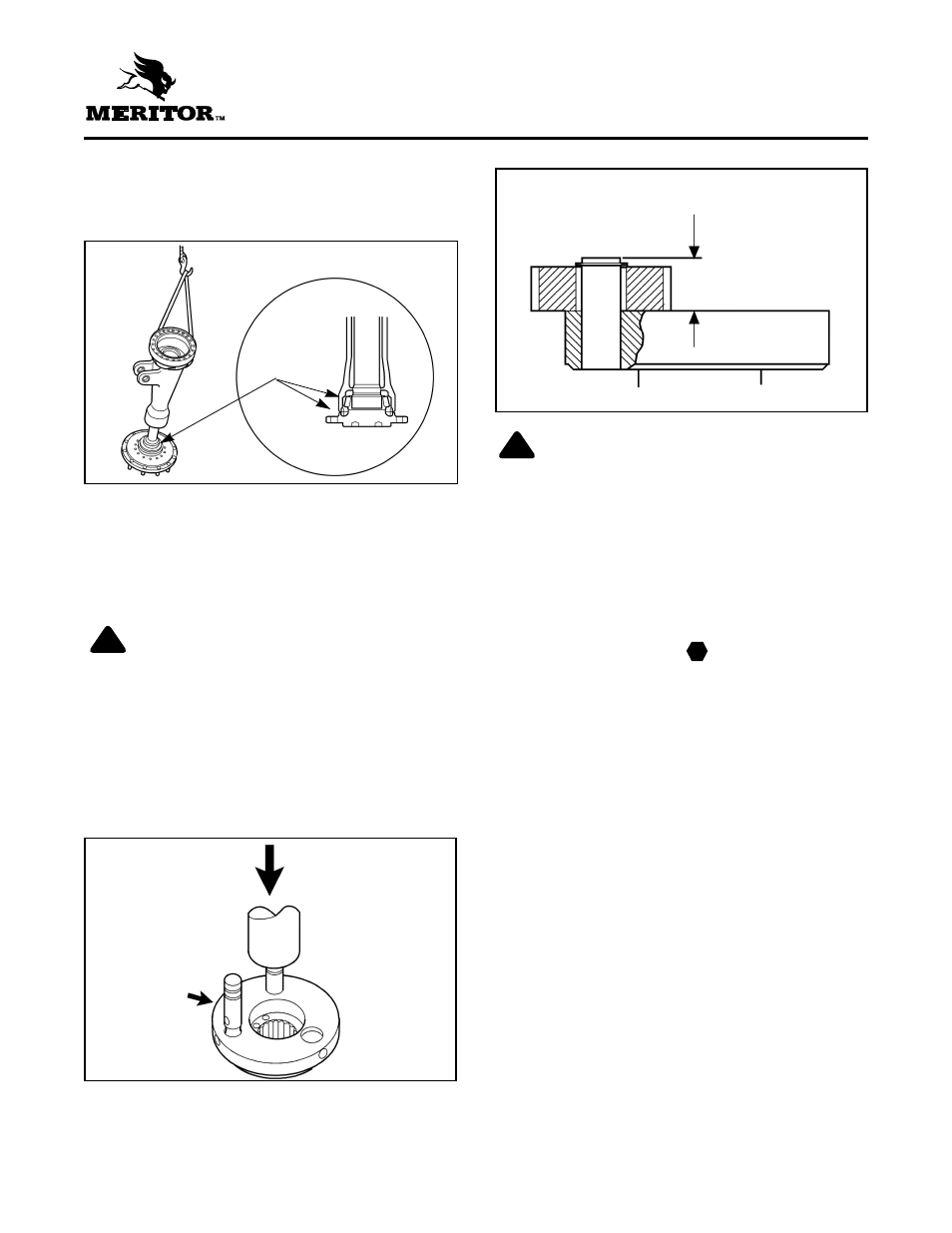

2. Install Duo-Cone oil seal into axle shaft and into

axle shaft housing bore as specified on page 18.

Figure 4.37.

3. With a correct size sleeve, use a press to install

flange side cone bearing. Install axle shaft into

axle shaft housing. Figure 4.37.

Assemble Trumpet Assembly

WARNING

Observe all WARNINGS and CAUTIONS provided

by the press manufacturer concerning press

operation to avoid serious personal injury and

possible damage to components during

assembly and installation procedures.

1. Use press to install new planetary pin into spider.

Make sure proper dimensions are used and holes

are aligned. Figures 4.38 and 4.39.

!

Figure 4.37

DUO-CONE

OIL SEAL

WARNING

To avoid serious personal injury, be careful when

using Loctite. Follow the manufacturer’s

instructions for safe use to prevent irritation to

eyes and skin. Wash after skin contact. If the

Loctite gets in eyes, flush with water for 15

minutes. Have eyes checked by a doctor.

2. Apply Medium Torque liquid adhesive, Loctite 241

or Three Bond 1334, to threads of planetary gear

axle lock capscrews. Install and tighten to

17-23 lb-ft (23-31 N•m).

!

Figure 4.38

Figure 4.39

ALIGNED

HOLES

44.60

44.80

T