Viii. front motor begin point – Gradall 534C-10 (2460-4129) Service Manual User Manual

Page 69

Definition: The point at which the front motor begins to stroke toward minimum displacement.

Reason for Front Motor Begin Point Check

Without proper adjustment, machine speed on a flat, smooth surface will not meet specifications. The motor may

not be shifting to a maximum speed position.

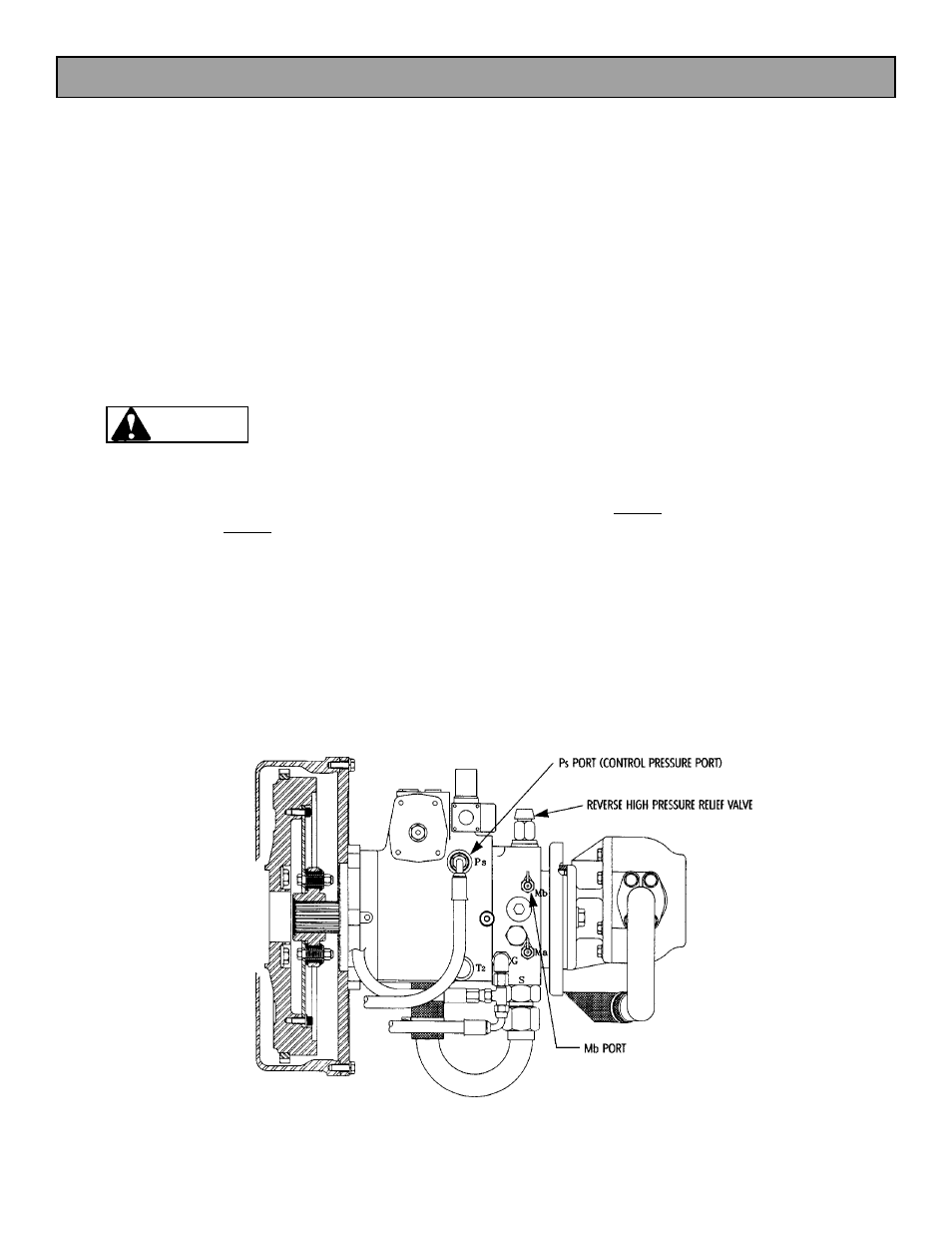

Install a high pressure gauge (10,000 PSI), hose and adapter on MB port on the drive pump. Adjust the reverse

high pressure relief valve to 3,300 PSI by loosening the locknut. The reverse high pressure port relief is on the

top left of the pump. Install adopter, test port (P/N 7713-3089), #6 run tee and low pressure gauge (1,000 PSI)

into the Ps port of the pump. (Ps port is connection for the inching valve hose). Set the parking brake and block

the tires to prevent movement of the machine. Machine should be in 2WD. Shut off the machine. Remove plugs

from G and M ports of the front drive motor. G port is found at the bottom of the front drive motor controls.

M port locates at the top left side of the controls.

See Figure 18 and Figure 19. Install test ports (P/N 7713-

3089) in place of the plugs. Attach a high pressure gauge (10,000 PSI) to both test ports.

During the next two steps, to prevent excessive heat in the hydraulic oil and possible

damage to hydraulic components, do not operate for more than 30 seconds at a time.

Start engine and raise RPM until gauge on Ps port is at 240 PSI. Maintain this RPM and pressure throughout

the test. With pressure on Ps port at 240 PSI, the pressure at G port should read 3,300 PSI. Adjust “begin” point

screw on the motor so that M port on motor sees opproximately 1,650 PSI. (NOTE! Begin point screw adjustment

is very sensitive.) NOTE! The pressure on M port will not be steady. This is the pressure that shifts the motor to

maintain minimum displacement.

Under normal operating conditions, the 3,300 PSI on G port required to shift the motor will not be constant.

When this pressure is reached, the motor shifts. Since the pressure supplied is constant, the motor will not stay in

a partially shifted position. Reset the reverse high pressure relief valve to 6,800 PSI. Use procedure # 9 drive

pump pressure to adjust this relief.

Wrench sizes required: 4mm allen and 10mm box.

FIGURE 18

MAIN PUMP ASSEMBLY (SIDE VIEW)

VIII. Front Motor Begin Point

WARNING

Form No. 29633 3/97

534C-9 & 534C-10

HYDROLASTIC DRIVE PERFORMANCE CHECKS MANUAL

17