Ks series, General pump – General Pump KS Repair Manual User Manual

Page 7

GENERAL PUMP

A member of the Interpump Group

KS SERIES

2.1.3 Disassembly/Assembly of Bearing and Shims

The type of bearings (taper roller) ensures the absence of axial clearance on the crankshaft. the shims are to

be determined to reach this purpose. To disassemble / assemble, or to replace them if needed, carefully fol-

low the instructions below:

A) Disassembly/Assembly of the crankshaft without replacing the bearings

After removing the side covers, as indicated in paragraph 2.1.1, check the rollers and their races for wear; if

all parts are in good condition, thoroughly clean the components with a suitable degreaser and grease them

again evenly using lubricating oil.

The same shims can be used again, being careful to fit them under the cover on the sight glass side. After

installing the complete unit (sight glass flange+ shaft + engine side flange), check that the shaft’s rolling

torque - with the connection rods free - is at least 3 ft. lbs (4 Nm), max 5 ft. lbs (7 Nm).

To position the two side covers on the crankcase, initially use 3 M6x40 screws as shown in fig. 7, and then

the fastening screws.

The shaft’s rolling torque (with connecting rods coupled) must not exceed 6 ft. lbs (8 Nm).

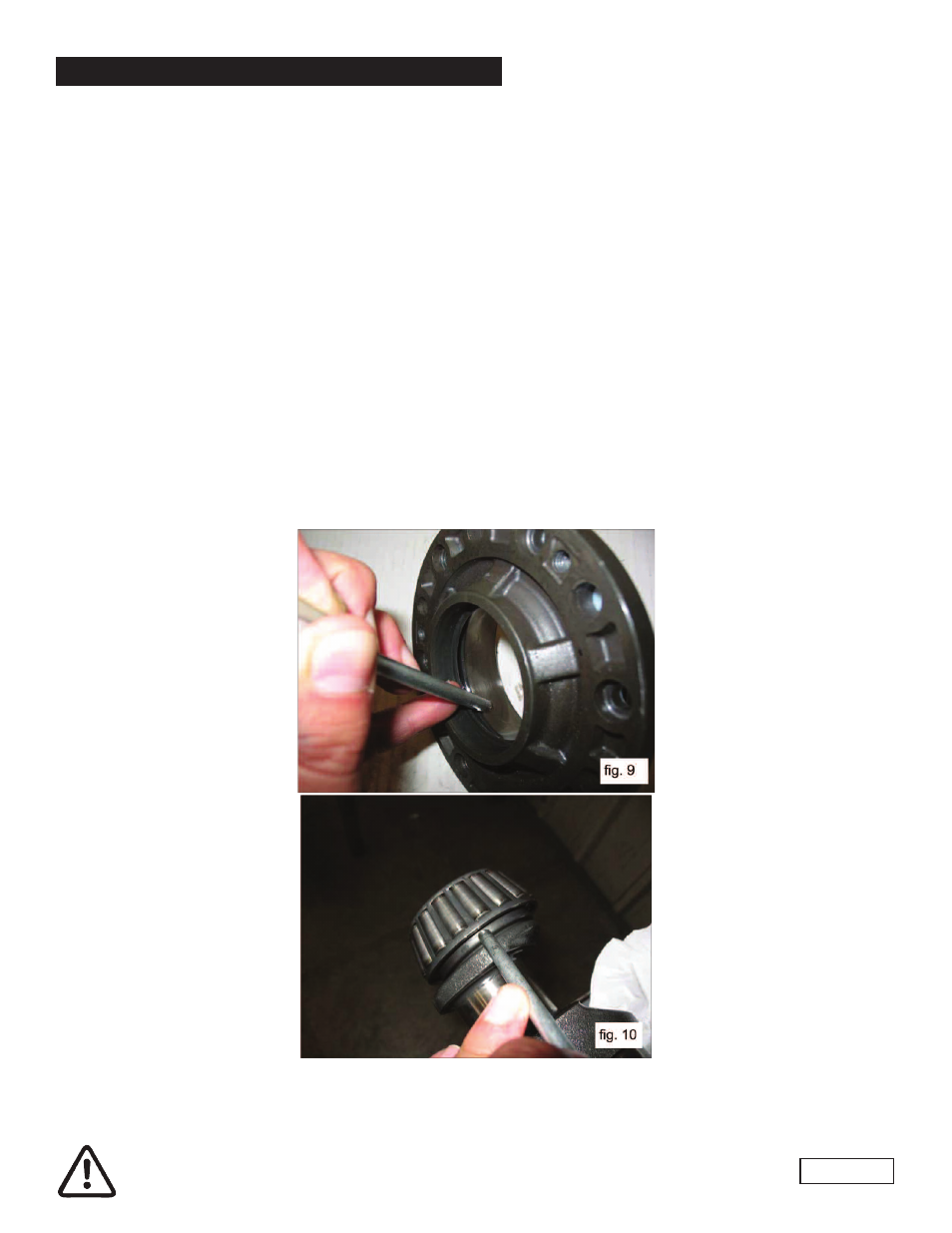

B) Disassembly/Assembly of the crankshaft with bearing replacement

After disassembling the side covers as indicated in paragraph 2.1.1, remove the outer ring nut of the bearings

from their covers and the inner ring nut, with the remaining part of the bearing, from the two shaft

extremities using a standard pin extractor or similar tool as indicated in figures 9-10.

The new roller bearing can be mounted at room temperature with a press or fly press, it is necessary to lay

them on the lateral side of the relevant ring nuts with appropriate rings. The driving operation can be facilitiat-

ed by heating the relevant parts at a temperature ranging between 250

o

-300

o

F(120

o

-150

o

C), making sure

that the ring nuts are correctily fitted into their seats

Never invert the parts of the two bearings.

Page 7

Ref 300902 Rev.A

07-12