Ks series – General Pump KS Repair Manual User Manual

Page 15

GENERAL PUMP

A member of the Interpump Group

KS SERIES

Page 15

Ref 300902 Rev.A

07-12

fig. 34

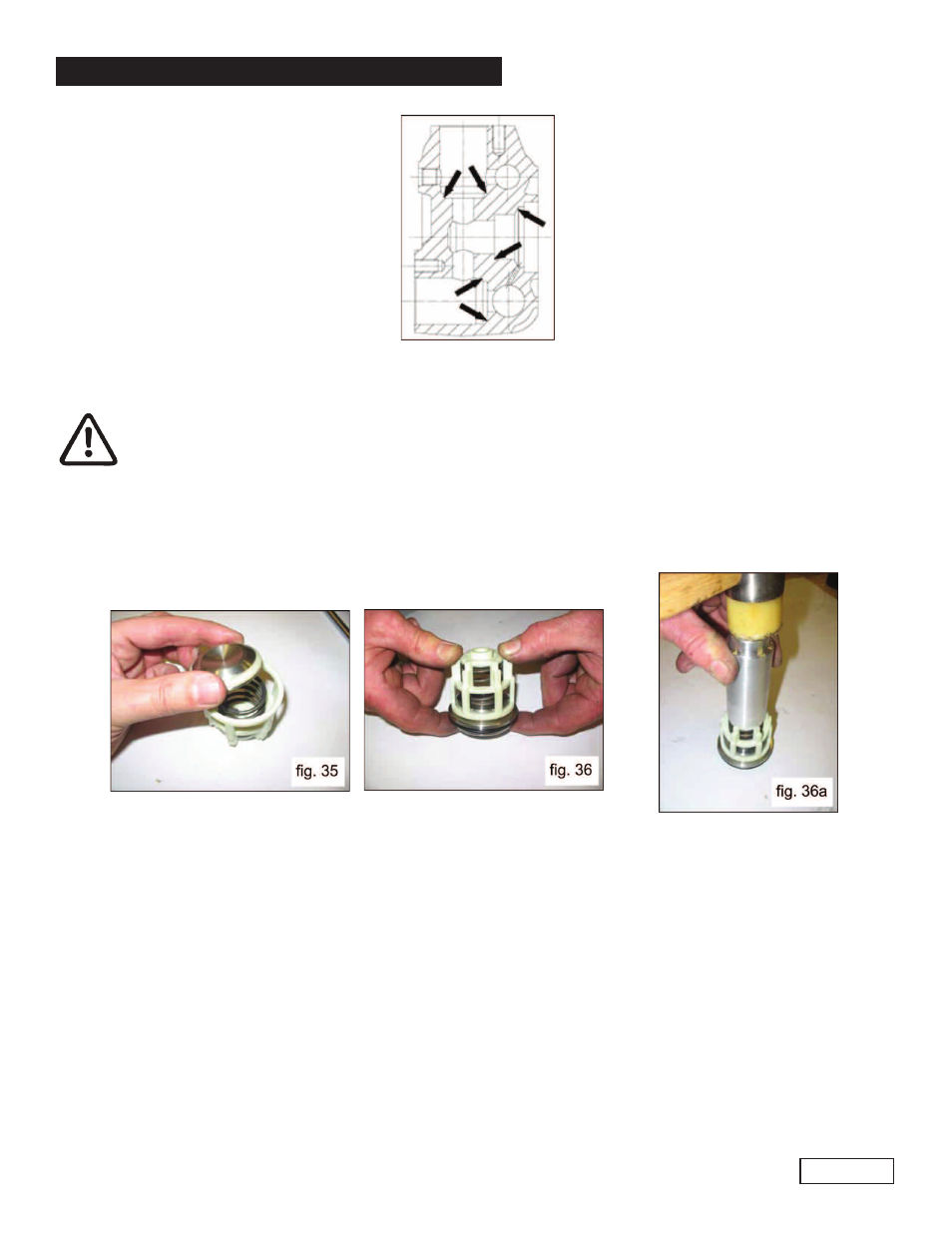

Proceed with reassembly by inverting the procedure indicated in paragraph 2.2.1, paying particular attention

to:

During the assembly of the suction and delivery valve units (fig. 35-fig. 36 - fig. 36a) do not

invert the suction springs with the previously disassembled delivery springs:

a. Suction springs “white”

b. Delivery springs “black”

To facilitate the insertion of the valve guide into its seat, use a pipe that lays on the horizontal shoulders of

the guide (fig. 36a) and use a hammer acting on the entire circumference.

Insert the suction and delivery valve units checking that they are thoroughly inserted in the head seat.

Therefore apply the valve covers and proceed with calibrating the related M12x35 screws with a torque

wrench as indicated in Chapter 3.

2.2.3 Disassembly of the head - seals

The replacement of the seals is necessary if water leaks are detected from the draining holes located at the

rear of the crankcase, and in any case within the intervals indicated in the preventive maintenance table in

Chapter 11 of the Owner’s Manual.

Remove the 4 closing plugs for the holes on the suction valve cover (fig. 37). Unfasten the two external head

screws M12x160, replacing them with two threaded bars M12 (1, fig. 38) to avoid damaging the plungers,

then proceed with removing the rest of the screws.