Safety instructions, Operating pressure – Fill-Rite TS AA Mechanical Precision Meter User Manual

Page 8

SAFETY INSTRUCTIONS

Make sure that all necessary safety precautions have been

taken, including proper clothing, personal safety equipment

and fire safety equipment if required.

Before Start-Up of the Flow Meter, make certain that:

1. The meter is properly mounted, secured and piped.

2. All connections are tight.

3. All bleed and drain valves are closed.

4. Do NOT smoke near meter, or use meter near an open

flame, when metering flammable liquids. Fire or Explo-

sion could result.

5. This meter is not intended for use on liquids, which re-

quire 3A Sanitary equipment for human consumption. It

may be used on edible liquids, which do not spoil easily,

such as vegetable oils, liquid sweeteners & similar.

Install the Flow Meter and Accessories in compli-

ance with all applicable Local, State & Federal

Construction, Electrical and Safety Codes.

Installation

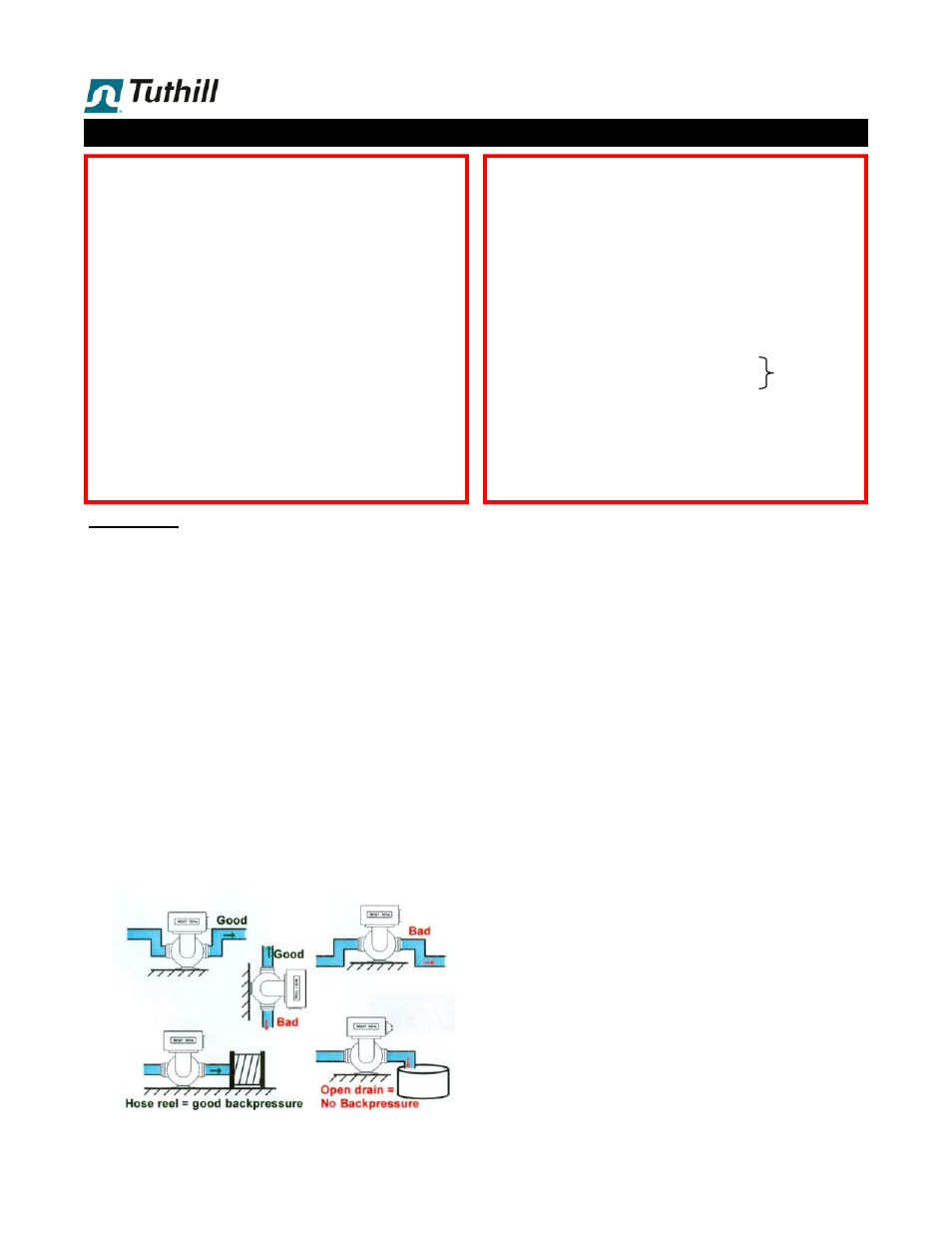

Positive Displacement meters are designed to operate full

of liquid. The meter should be installed in a manner, so

that it remains full of liquid at all times.

The flow meter is not designed to operate on air, but the

design and materials of construction allow for operation

on vapor for short periods of time without damage to the

oval gears or flow meter internals.

The meter should always be supported by bolting firm-

ly to a solid platform or foundation. Never use the con-

necting pipe as the sole means of support.

For most accurate measurement, the flow meter should

operate with some backpressure (avoid delivering into an

open vessel).

The flow meter can operate with liquid going Left-to-Right,

Right-to-Left or Vertical Up, but it must be installed with

rotor shafts in horizontal position

(= with vertical end

covers). Failure to observe this will impact negatively on

flow meter accuracy.

1 . 8

Installation, Start-Up & Operation

OPERATING TEMPERATURE

TS Series V●● assemblies are rated for operation

from -40°F/+180°F (-40°C/+80°C). However:

They are not suitable for cryogenic service.

When operating temperature exceeds +120°F

(+50°C), pressure rating is reduced. Please

refer to FPP Technical Manual for details.

OPERATING PRESSURE

Maximum

non-shock

Operating Pressure is:

Flow Meter/Strainer : 400

PSI

(28

BAR

)

at 100°F

Air Eliminator/Valves: 150

PSI

(10

BAR

) (= +38°C)

The flow meter should never be operated in excess of this

pressure. Care should be taken to eliminate thermal and

hydraulic shock conditions, so that system pressure never

exceeds Maximum Working Pressure rating.

Hydraulic shock

can be harmful to flow meter and other

system components. Consideration to eliminate hydraulic

shock should be given in selection of pump and design of

the piping system.

Protective caps installed in flow meter flanges prior to

shipment should remain in place until you are ready to

install in the piping system.

It is recommended that a Strainer be installed upstream

of each flow meter, to prevent damage from foreign mat-

ter, such as welding slag, pipe scale or parts breaking off

other equipment. If using an FPP right-angle strainer:

Inlet can be either from the front or the rear of the

strainer (inlet flange & strainer basket cover have same

bolt pattern, and can be reversed in the field).

Allow adequate space for removal of strainer basket

cover, so strainer basket can be cleaned.

10” for models TS10A, TS15A & TS20A.

11” for model TS30A

If no fluid is specified, strainer basket comes standard

with 40 mesh.

We also offer:

20 mesh for high viscosity liquids, such as heavy

fuel oil, automotive lube oils, liquid sugars, molas-

ses, etc.

100 mesh for gasoline, alcohol & solvent service.

200 mesh for LPG (Propane) service.

Flush the system to remove all debris, scale and welding

slag prior to flow meter installation. If this is not possi-

ble, temporarily remove rotors (oval gears), and reinstall

after the system has been flushed.

Continued