Flow meter calibration – Fill-Rite TS AA Mechanical Precision Meter User Manual

Page 12

When prover/master meter reading is

less than

flow

meter

register reading,

add percentage

calculated

by turning the calibrator in the

+ volume direction

.

When prover/master meter reading is

more than

flow

meter register reading

,

subtract percentage

calcu-

lated by turning the calibrator in the

- volume direction

.

After correcting calibrator setting, circulate product

through the flow meter for a few minutes. Then perform

at least 3 more tests, to confirm flow meter accuracy &

repeatability.

If the flow meter does not repeat, it will likely require a

new set of rotors (oval gears).

Before ordering new gears, inspect the measuring

chamber for scratches or wear. If the measuring

chamber is scratched or scored beyond what can be

smoothed with emery paper, flow meter case should

be replaced.

Finally:

Re-seal the flow meter.

Enter date and % correction on the permanent flow

meter record.

As long as degree of change is moderate, the flow meter is

in good condition.

If there is a sudden significant jump in correction required,

the rotors are likely about worn out. Rotor replacement

should be considered now, rather than letting further wear

cause rotors to start rubbing on flow meter housing.

1 . 12

Flow Meter Calibration

Procedures & Methods

Flow meters used in systems where the flow rate can fluctu-

ate, should be tested at minimum, intermediate & maximum

flow rates. In non-W&M service, a flow meter always oper-

ating at a steady flow rate, can be tested at that flow only.

All tests should be repeated 3 times to confirm repeatability.

All tests should be of at least 60 second duration, to mini-

mize the effect of flow meter error during start-up and shut-

down.

After calibrating a known volume (X) into an accurate

prover, through a master meter, or against a certified

scale with adequate resolution, compare with register

reading (Y) and calculate correction:

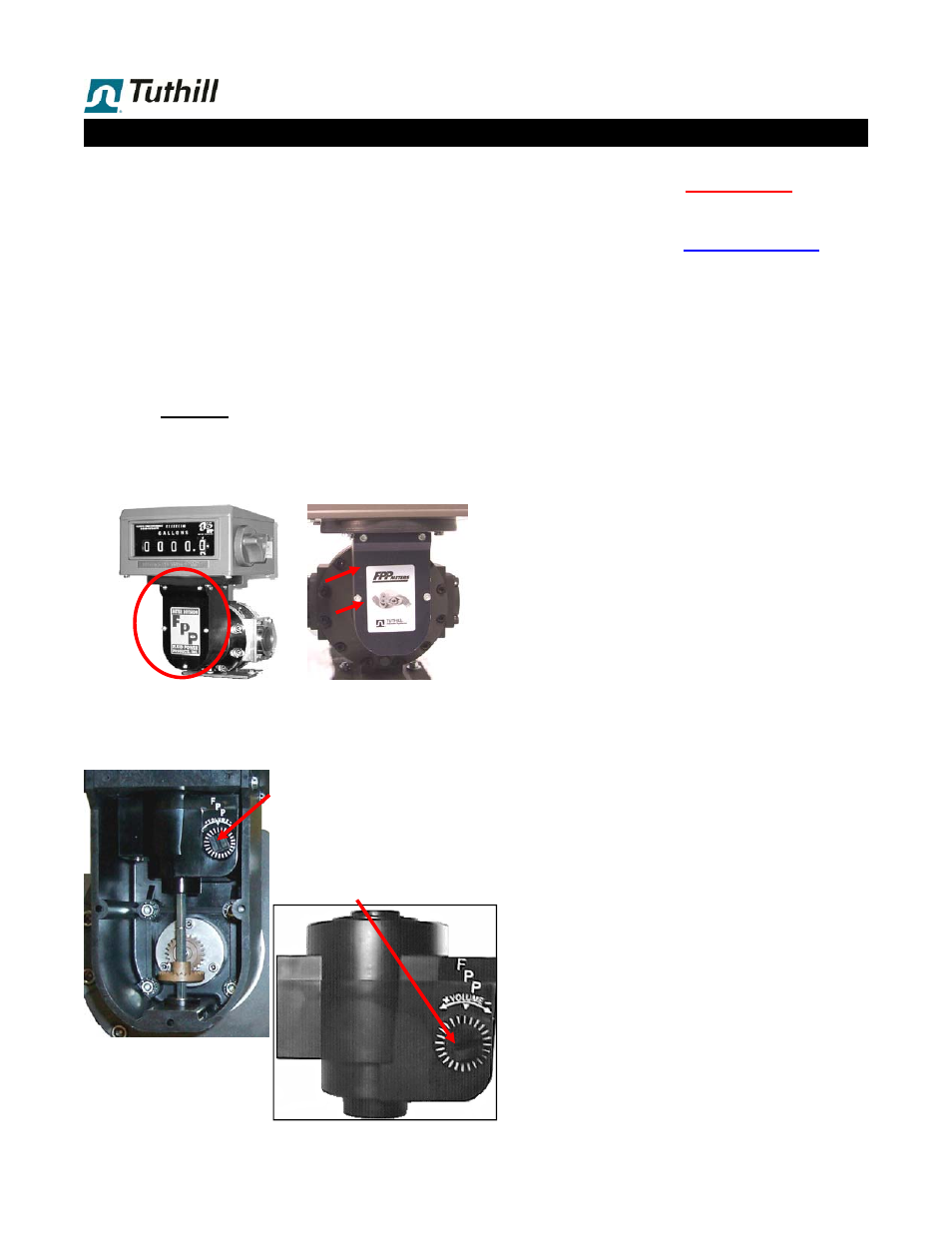

When re-calibration has established that a correction is

required, remove the dust cover (15) from the RAD (14 =

right angle drive adaptor), by detaching screws (16 & 17).

This provides access to the calibrator assembly (19),

which has a dial on the front, and is marked with direc-

tions for + and - Volume. Each graduation of this dial

represents approx. 0.06% change

The dial has a

slot for a

screw driver

in the center, so

the setting can be changed.

As you turn the center, you will

hear two ‘clicks’ for each grad-

uation mark. Each ‘click’ rep-

resents approximately 0.03%

change in the setting.

Do NOT change setting,

unless re-calibration of the

flow meter has established

the need for correction.

19

X - Y

X

x 100

= % correction

17

15

16

14

19