Changing direction of flow – Fill-Rite TS AA Mechanical Precision Meter User Manual

Page 10

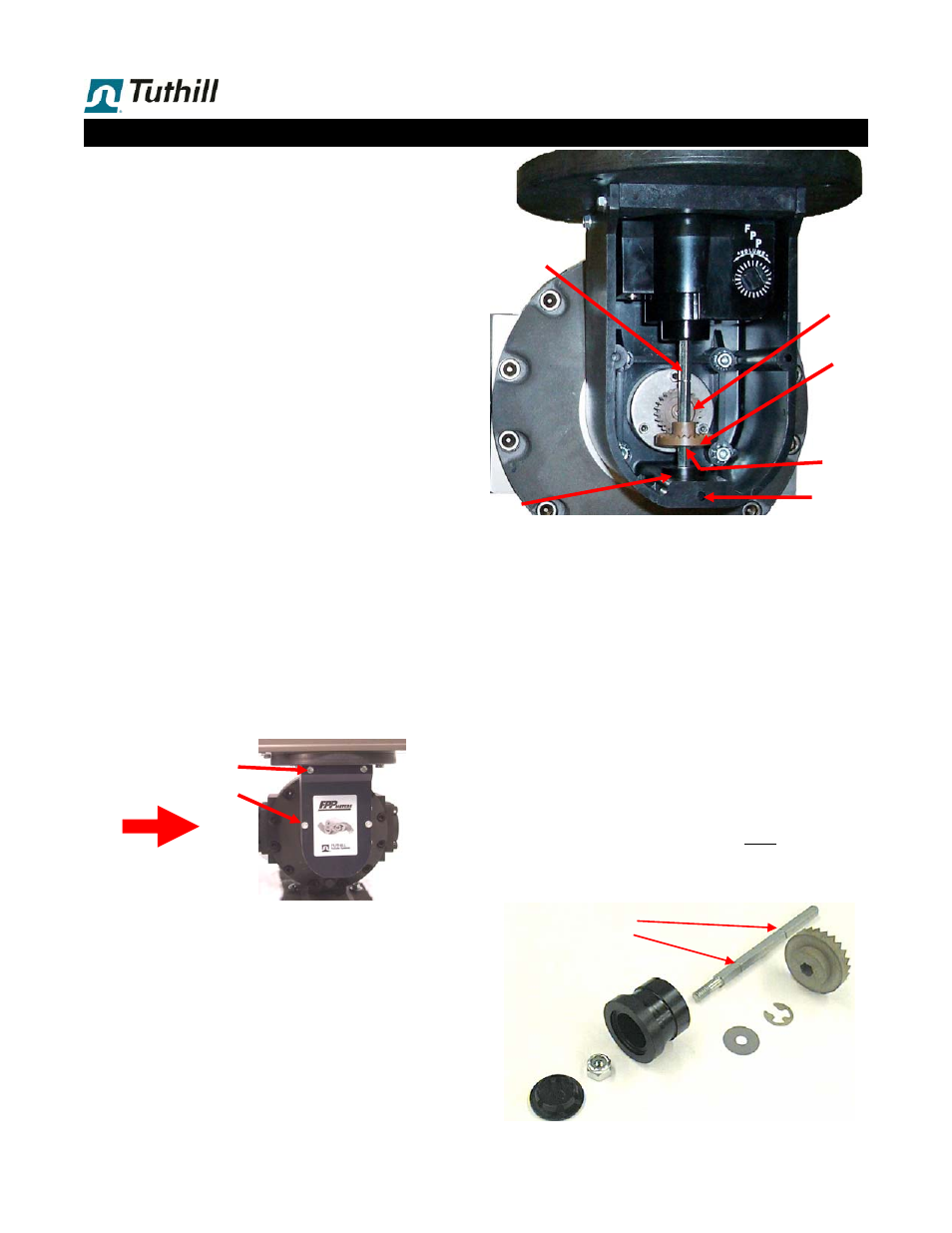

Now loosen the set screw (18) with a 3/32” Allen wrench,

to release the calibrator drive shaft bushing (21B).

Slide the calibrator drive shaft bushing (21B) out of the

bottom of the RAD (14).

Pull the calibrator drive shaft assembly out of the RAD.

Remove the face gear (11E), and turn it 180º, so that the

gear teeth are facing in the opposite direction from the

original installation.

Re-assemble the parts in reverse order.

Make sure that the calibrator drive shaft bushing flange

(21B), is tight against the RAD (14).

Tighten the hex nut (21C)

Re-install the E-ring (21F) in the appropriate grove (

in

the above example, the E-ring now goes into groove above

the pinion

).

Inspect to make sure that there is slight backlash be-

tween the pinion gear (11D) and the face gear (11E).

They must engage without binding or slipping.

1 . 10

Changing Direction of Flow

TS Series flow meters can operate in either direction.

Standard assembly, when facing the flow meter, has the

flow going Left-to-Right, unless specified differently at time

of the order. A label with the word INLET is placed on the

inlet flange, as assembled at the factory.

When the meter is first installed, check that the register is

turning correctly when you start the flow. If it is not (or it is

attempting to run backwards), check position of the face

gear (11E) on the calibrator drive shaft (21A), and if neces-

sary correct the position of the face gear versus the packing

gland pinion (11D) as explained below.

Left-to-Right flow = Face gear below packing gland pinion

Right-to-Left flow = Face gear above packing gland pinion

The direction of flow can be changed in the field. This re-

quires the following steps:

Any accessories (strainer and/or preset valve) attached to

the flow meter must be moved to the opposite side.

Strainer inlet is standard from the front. When mov-

ing the strainer to Right-to-Left position, switch the

inlet flange and strainer basket cover. If rear inlet is

preferred, leave flange & basket cover as is, when

moving the strainer.

Standard outlet on Preset Valve or Air Check Valve

is towards the front. When moving the valve to Right-

to-Left position:

Air Check Valve: Rotate the valve 180º, then in-

stall tubing connecting air eliminator to the valve.

Preset Valve: Rotate the valve 180º. Disassem-

ble the linkage, and re-assemble mirror image to

original assy.

Reverse the position of the face gear (11E) on the cali-

brator drive shaft (21A).

First remove screws (16 & 17) to detach the dust cover

(15) from the RAD (14 = Right Angle Drive) adaptor.

Now refer to photo in next column.

Notice position of the face gear (11E) on the calibrator

drive shaft (21A) in relation to the packing gland pinion

(11D).

Remove E-ring (21F) with a screwdriver or small pliers.

As shown, the E-ring is installed below the face gear,

where it is not visible in the photo.

11E

11D

21A

18

INLET

19

14

INLET

21B

16

17

15

14

21E

21B

21C

21D

21E

21F

11E

21A = Drive shaft with 2 grooves:

Upper

Lower